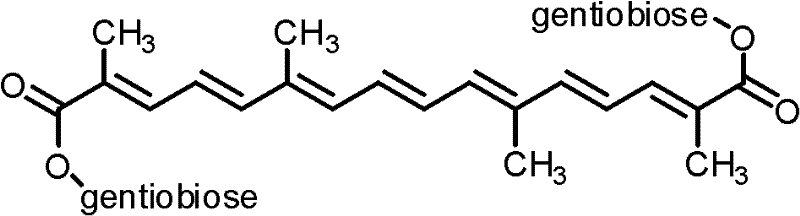

Method for extracting gardenia yellow pigment from gardeniae longicarpae fruit

A technology of gardenia yellow pigment and water gardenia, applied in chemical instruments and methods, azo dyes, organic dyes, etc., to achieve the effect of good product purity, short process route and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Put 10g of dried water gardenia fruits with a moisture content of 9% into a ball mill together with 1.0g of sodium carbonate, and ball mill at a speed of 1920rpm for 5min; take out the ball mill powder, add 110g of water to the obtained ball mill powder, and stir at 50°C for 60min; filter , take the supernatant, pass through the HPD-100 macroporous resin chromatography column, elute with 80wt% ethanol aqueous solution of 2 times the column volume, collect the eluate, concentrate, evaporate the solvent, and dry to obtain 0.50 g of gardenia yellow pigment, The yield of the product is 5%, the color value is 370, and the OD value is 0.36.

Embodiment 2

[0035] Put 10 g of dried water gardenia fruits with a moisture content of 9% into a ball mill together with 20 g of sodium bicarbonate, and ball mill for 60 min at a speed of 2220 rpm; take out the ball mill powder, add 300 g of water to the obtained ball mill powder, and stir for 5 min at 30° C.; filter , take the supernatant, put it on HPD-450 macroporous resin chromatography column, elute with 60wt% ethanol aqueous solution of 10 times the column volume, collect the eluate, concentrate, evaporate the solvent, and dry to obtain 0.46g of gardenia yellow pigment, The yield of the product is 4.6%, the color value is 395, and the OD value is 0.31.

Embodiment 3

[0037] Put 10g of dried water gardenia fruits with a water content of 9% into a ball mill together with 5g of potassium bicarbonate, and ball mill at a speed of 2220rpm for 15min; take out the ball mill powder, add 75g of water to the obtained ball mill powder, and stir at 45°C for 50min; filter , take the supernatant, put it on a HPD-600 macroporous resin chromatography column, elute with 60wt% ethanol aqueous solution of 8 times the column volume, collect the eluate, concentrate, evaporate the solvent, and dry to obtain 0.53g of gardenia yellow pigment, The yield of the product is 5.3%, the color value is 356, and the OD value is 0.41.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com