Process method for producing antibacterial and deodorant polyester fibers by adopting monocarboxy-chitosan

A technology of monohydroxy chitosan and process method, which is applied in the direction of fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., to achieve the effects of low production energy consumption, green production process, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

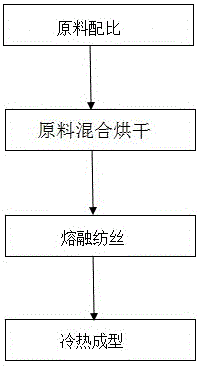

[0014] Embodiment: a kind of processing method that adopts water-soluble antibacterial monocarboxyl chitosan to produce antibacterial deodorant polyester fiber, comprises the steps:

[0015] (1) Raw material ratio: Dissolve light yellow monohydroxy chitosan solid slices in water to make a 75% aqueous solution of water-soluble antibacterial monocarboxy chitosan;

[0016] (2) Mixing and drying of raw materials: fully mix polyester melt with 75% water-soluble antibacterial monocarboxyl chitosan aqueous solution for half an hour, and then put it into a vacuum dryer for drying. The pre-drying temperature is 106°C. The drying time is 2 hours, then the temperature is raised to 120°C and dried for 5 hours, and the moisture content of the dried polyester melt is kept below 30ppm;

[0017] (3) Melt spinning: transport the dried mixed raw materials in step (1) to six-box screw extruders for heating and melting, and control the temperature from one to six. The temperature of each box is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com