Method for producing cordyceps sinensis feed additive and product

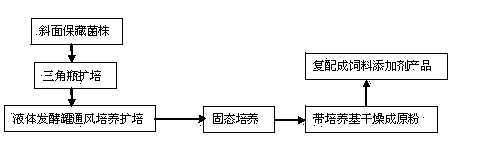

A technology of feed additive and Cordyceps sinensis, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, animal feed, etc., can solve the problems of low water content in the medium, difficult control of temperature, humidity and other culture conditions, and low quality. Achieve the effects of shortening the fermentation cycle, promoting heat and mass transfer, and promoting oxygen absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Example 1

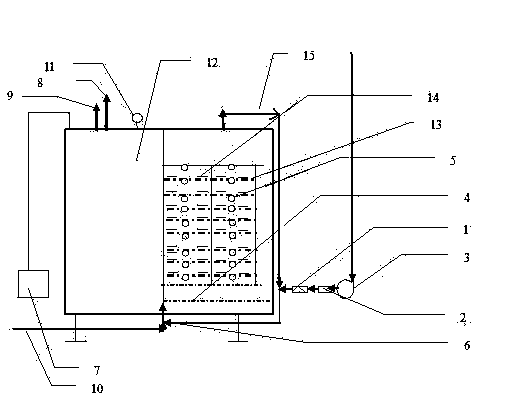

[0029] Primary seed culture: medium (g / L): potato 200, glucose 20, peptone 2, KH 2 PO 4 0.5, MgSO 4 ·7H 2 O 1.0, agar 20, pH natural. The slant was transferred to the Cordyceps militaris strain and high-pressure steam sterilized Erlenmeyer flask containing the above medium 200 mL / 500 mL, placed on a shaker at 150 r / min, and cultured at 18 °C for 4 days.

[0030] Secondary seed culture: cultured in a 7 L liquid mechanically stirred fermenter produced by Zhenjiang Dongfang Bioengineering Equipment Technology Co., Ltd. Medium: 35 g brewer's grains, 20 g glucose, 10 g beer dry yeast, KH 2 PO 4 3 g, MgSO 4 ·7H 2 O 1.5 g, add water to 1000 mL, pH 6.5, sterilize at 121 °C for 40 min. Ventilation V / V: 0.6; rotating speed: 150 r / min; tank pressure: 0.05 MPa, culture at 20°C for 3.5 days.

[0031] Solid medium formula: 15% dry brewer's grains, 5% rice flour, 65% wheat bran, 5% silkworm chrysalis powder, 10% beer dry yeast, KH 2 PO 4 0.05%, MgSO 4 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com