Environment-friendly polymer cement wall waterproof slurry and preparation method thereof

A technology of waterproof slurry and polymer, which is applied in the field of building materials, can solve the problems of reducing the service life of buildings, high maintenance costs, affecting life, production order, etc., and achieves the advantages of reducing air bubbles, green production technology, and excellent construction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

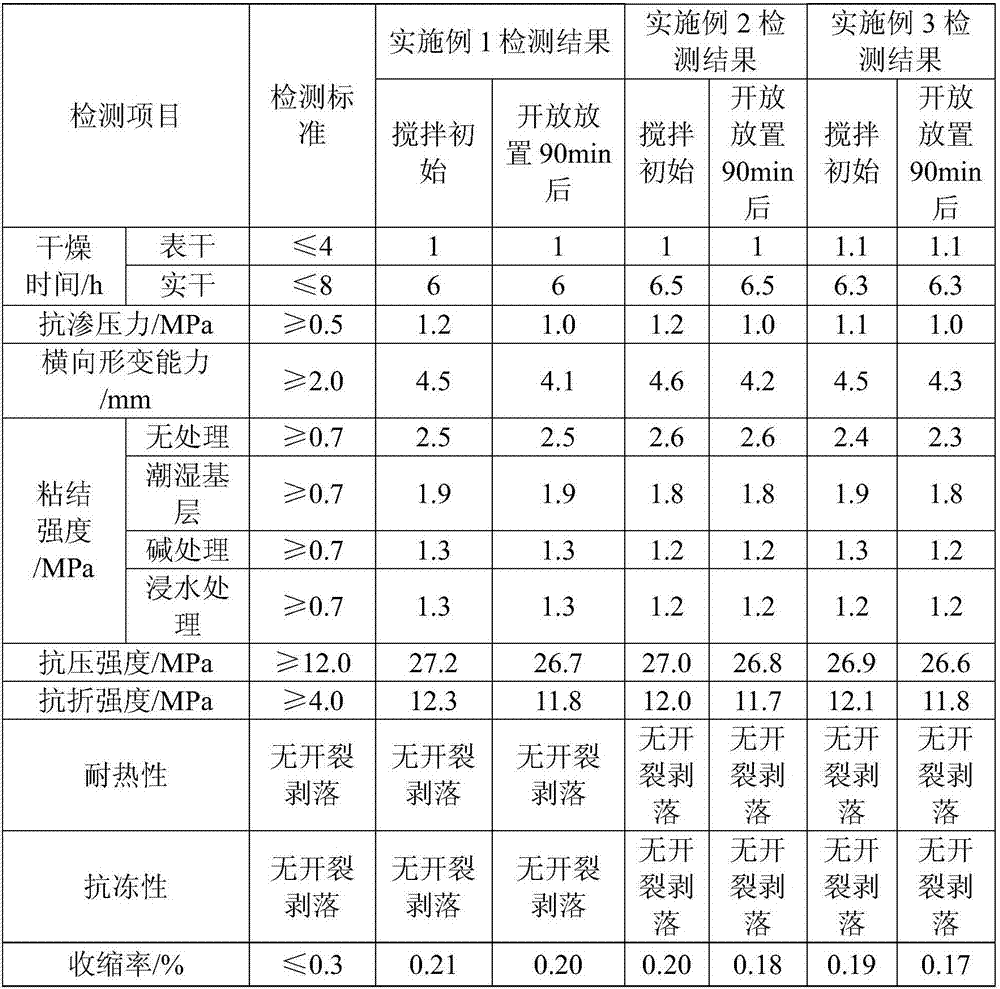

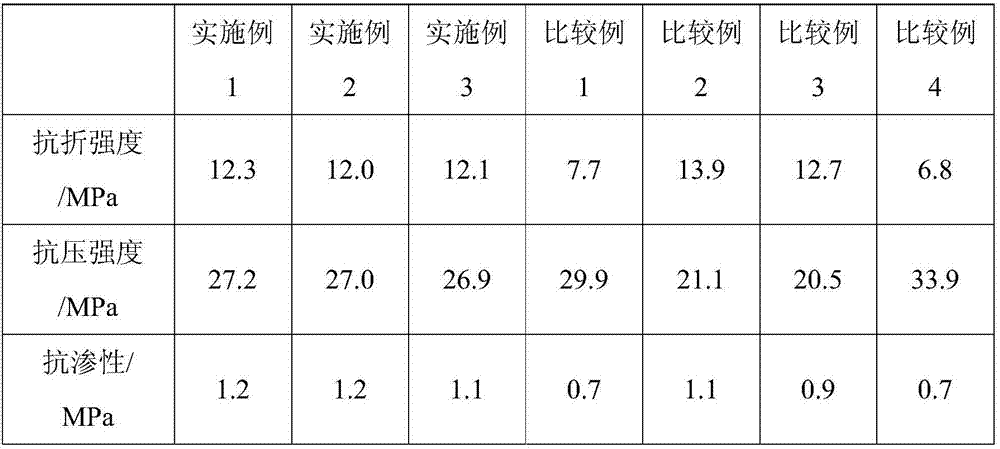

Examples

Embodiment 1

[0044] (1) Preparation of liquid material: First, add 490g of water and 5g of environmentally friendly sodium salt dispersant into the stirring pot, turn on the machine at a speed of 180r / min, and then add 2 / 3 of the total defoaming dose of defoaming agent, After the dispersion is uniform, add 500g of polymer emulsion, then adjust the rotation speed to 500r / min for dispersion, add a pH regulator to adjust the pH value of the material to 9.5, and after 30 minutes, adjust the dispersion speed to 180r / min min, then add the remaining defoamer, after stirring for 15 minutes, stop stirring, leave it to stand and filter to obtain the liquid material, the defoamer is composed of mineral oil defoamer and silicone oil defoamer with a mass ratio of 3:1 Composition, described polymer emulsion is made up of pure acrylic emulsion and styrene-acrylic emulsion that mass ratio is 1:4;

[0045] (2) Preparation of powder: first add 380g of cement, 380g of quartz sand, and 230g of heavy calcium i...

Embodiment 2

[0047] (1) Preparation of liquid material: First, add the required 550g of water and 6g of environmentally friendly sodium salt dispersant into the stirring pot, turn on the machine at a speed of 150r / min, and then add 2 / 3 of the total defoaming dose of defoaming agent, After the dispersion is uniform, add 450g of polymer emulsion, then adjust the rotation speed to 400r / min for dispersion, add a pH regulator to adjust the pH value of the material to within the range of 10, and after 30 minutes, adjust the dispersion speed to 150r / min min, then add the remaining defoamer, after stirring for 15 minutes, stop stirring, leave it to stand and filter to obtain the liquid material, the defoamer is composed of mineral oil defoamer and silicone oil defoamer with a mass ratio of 3:1 Composition, described polymer emulsion is made up of pure acrylic emulsion and styrene-acrylic emulsion that mass ratio is 1:3;

[0048] (2) Preparation of powder: first add 400g of cement, 350g of quartz s...

Embodiment 3

[0050] (1) Preparation of liquid material: First, add the required 450g of water and 4g of environmentally friendly sodium salt dispersant into the stirring pot, turn on the machine at a speed of 200r / min, and then add 2 / 3 of the total defoaming dose of defoaming agent, After the dispersion is uniform, add 550g of polymer emulsion, then adjust the rotation speed to 600r / min for dispersion, add a pH regulator to adjust the pH value of the material to 9.5, and after 30 minutes, adjust the dispersion speed to 200r / min min, then add the remaining defoamer, after stirring for 15 minutes, stop stirring, leave it to stand and filter to obtain the liquid material, the defoamer is composed of mineral oil defoamer and silicone oil defoamer with a mass ratio of 3:1 Composition, described polymer emulsion is made up of pure acrylic emulsion and styrene-acrylic emulsion that mass ratio is 1:5;

[0051] (2) Preparation of powder: First add 350g of cement, 400g of quartz sand, and 200g of he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com