High-selectivity acetonitrile preparation method

A technology selected from acetonitrile, applied in the field of organic matter preparation, to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

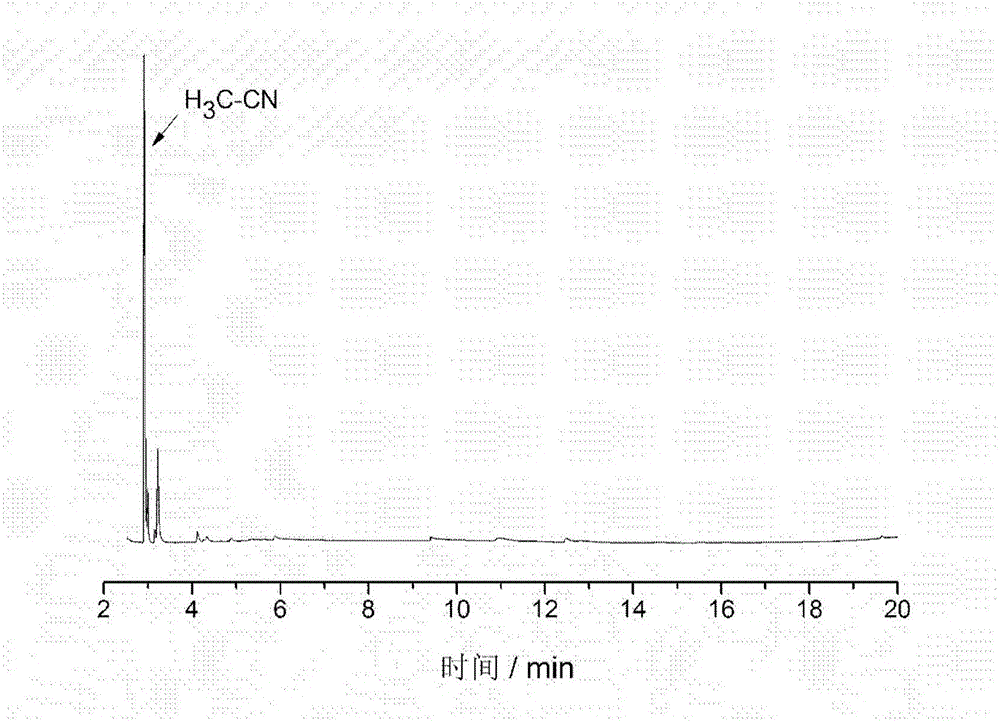

[0037] In this example, a quartz tubular reactor with a diameter of 10 mm and a length of 250 mm was used. In the reactor, the catalyst was supported by quartz wool. Install the quartz reactor in a temperature-controlled furnace. Reactor temperature was monitored by thermocouples inserted into the surface of the temperature-controlled furnace packed bed. During operation, use NH 3 , NH 3 / N 2 or NH 3 / He mixed gas is used as the carrier gas, and its flow rate is controlled by a gas flow meter. The powdery raw materials flow together with the carrier gas flow from the opening of the quartz tube to the pyrolysis interface. The reaction temperature is 200-900°C, and the carrier gas flow rate is 5-200mL / min. Liquid products flow from the reactor to the condenser and gaseous products are collected in gas sampling bags. Liquid and gaseous products were analyzed using a gas chromatograph.

[0038] As representative of several embodiments, the catalytic pyrolysis tests descri...

Embodiment 2

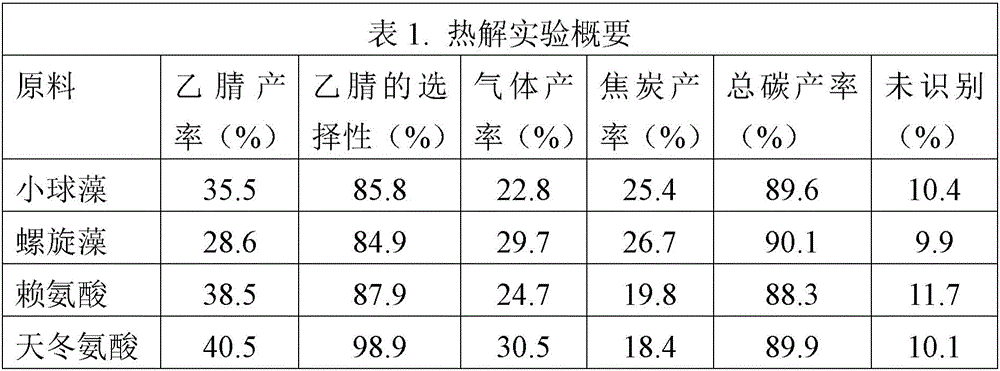

[0041] In this example, the preparation of acetonitrile by catalytic pyrolysis of different raw materials such as chlorella, spirulina, lysine, aspartic acid, duckweed, rapeseed cake, and activated sludge was tested.

[0042]

[0043]

[0044] Reaction conditions: the reaction temperature is 800° C.; the catalyst is ZSM-5; the flow rate of ammonia gas is 40 mL / min. Example 3:

Embodiment 3

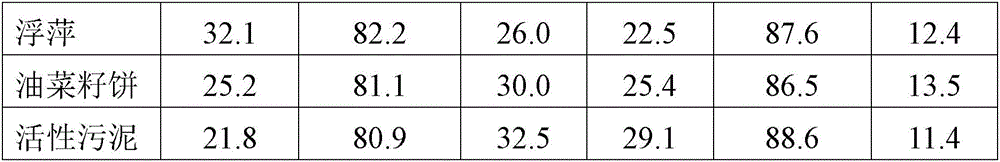

[0045] In this embodiment, the influence of different reaction temperatures on the yield and selectivity of acetonitrile was tested.

[0046]

[0047] Reaction conditions: the raw material is chlorella; the catalyst is ZSM-5; the flow rate of ammonia gas=40mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com