Preparation and application of composite dual-network zero-trans low-saturated fatty acid oleogel

A fatty acid and oil gel technology, which is applied in the application, skin care preparations, oil/fat/wax non-effective ingredients, etc., can solve the problems of oil gel oil leakage, unpleasant flavor, weak density and strength, etc., and achieve improvement Healthy, physical performance-enhancing, health-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A method for preparing a composite double-network zero-trans low-saturated oil gel, comprising the steps of:

[0077] (1) Weigh 1.5g of hydroxypropyl methylcellulose and dissolve it in 98.5g of water at 75°C, stir for 10 minutes to dissolve it, and use a high-speed homogenizer to homogenize at a speed of 10,000rpm for 5 minutes to obtain water foam;

[0078] (2) Transfer the water foam in step (1) to a -80°C refrigerator to freeze for 5 hours, then freeze-dry the frozen water foam at -80°C for 48 hours to obtain a porous airgel;

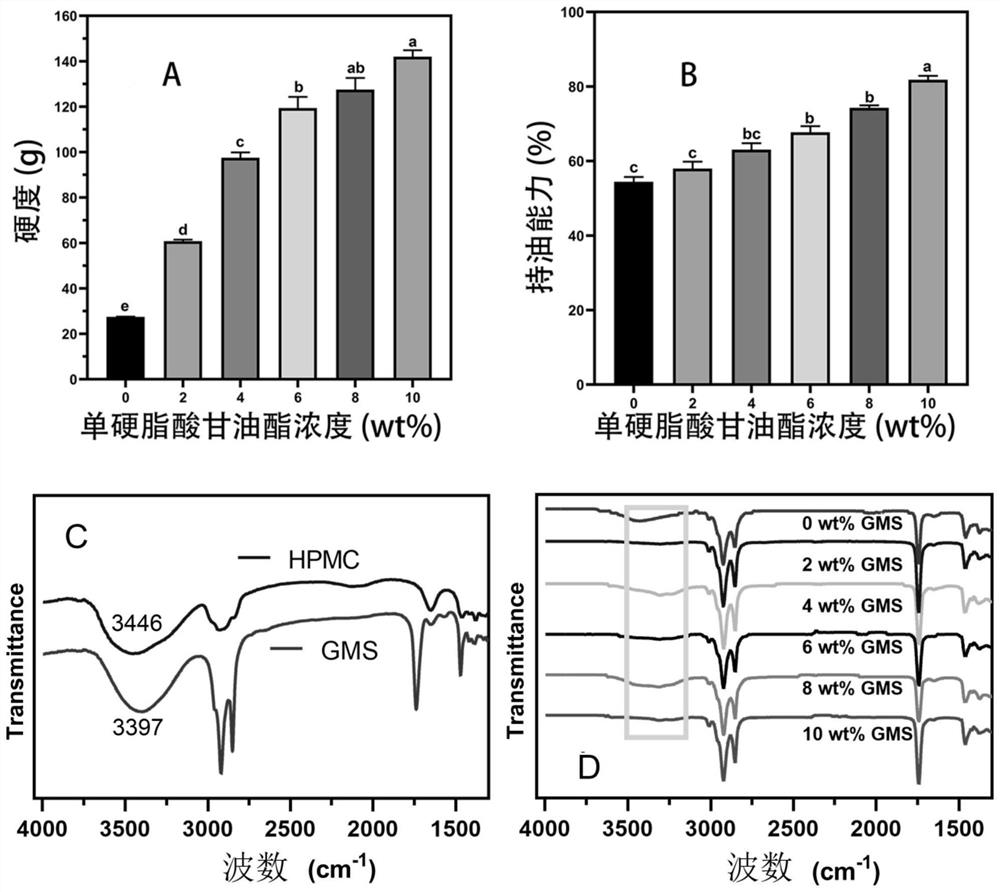

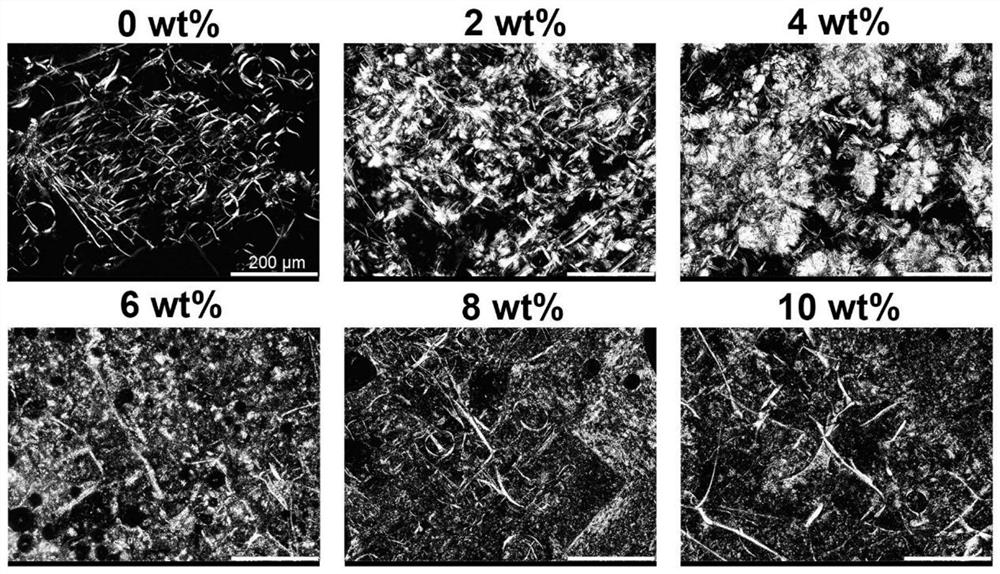

[0079] (3) Weigh 2, 4, 6, 8, and 10 g of glyceryl monostearate and dissolve them in 98, 96, 94, 92, and 90 g of soybean oil heated to 80°C, and stir for 10 minutes to dissolve it; solution;

[0080] (4) Put the porous airgel of step (2) in the 80°C glycerol monostearate oil solution described in step (3) to absorb oil for 30 minutes, take it out, and obtain the airgel that absorbs oil; The airgel was homogenized at 10,000 rpm for 2 minutes, ...

Embodiment 2

[0100] A method for preparing a composite double-network zero-trans low-saturated oil gel, comprising the steps of:

[0101] (1) Weigh 1.5g of hydroxypropyl methylcellulose and dissolve it in 98.5g of water at 75°C, stir for 10 minutes to dissolve it, and use a high-speed homogenizer to homogenize at a speed of 10,000rpm for 5 minutes to obtain water foam;

[0102] (2) Transfer the water foam in step (1) to a -80°C refrigerator to freeze for 5 hours, then freeze-dry the frozen water foam at -80°C for 48 hours to obtain a porous airgel;

[0103] (3) Weigh 50 g of soybean oil, palm oil, coconut oil, palm kernel oil, and palm stearin respectively and mix them with 50 g of soybean oil at 60° C., stir for 10 minutes to make them evenly mixed, and obtain mixed fats and oils.

[0104] (4) Put the porous airgel of step (2) in the mixed oil of step (3) at 60°C for 30 minutes to absorb oil to obtain an oil-absorbing airgel; then homogenize the oil-absorbing airgel at 10,000 rpm for 2 mi...

Embodiment 3

[0112] Application of embodiment 3 in cookie biscuit baking

[0113] A method for preparing cookies, comprising the steps of:

[0114] (1) Take the double-network zero-trans low saturated fatty acid oil gel prepared in Example 1 and carry out 1:1 mixing with commercially available butter to prepare mixed fat;

[0115] (2) Heat and soften 130 parts of mixed fat, then mix it with 65 parts of powdered sugar and 100 parts of white granulated sugar and whip to obtain a paste;

[0116] (3) Add 50 parts of eggs and 100 parts of low-gluten flour to the paste in sequence, beat the paste for 1 min to form a uniform batter;

[0117] (4) Put the batter into a piping bag and extrude the biscuit-shaped dough, and bake it in the oven for 20 minutes. During the first 10 minutes of baking, the temperatures of the upper and lower parts of the oven are respectively 170 and 150 ° C. After 10 minutes of baking, the temperatures of the upper and lower parts of the oven are 150°C, and finally obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com