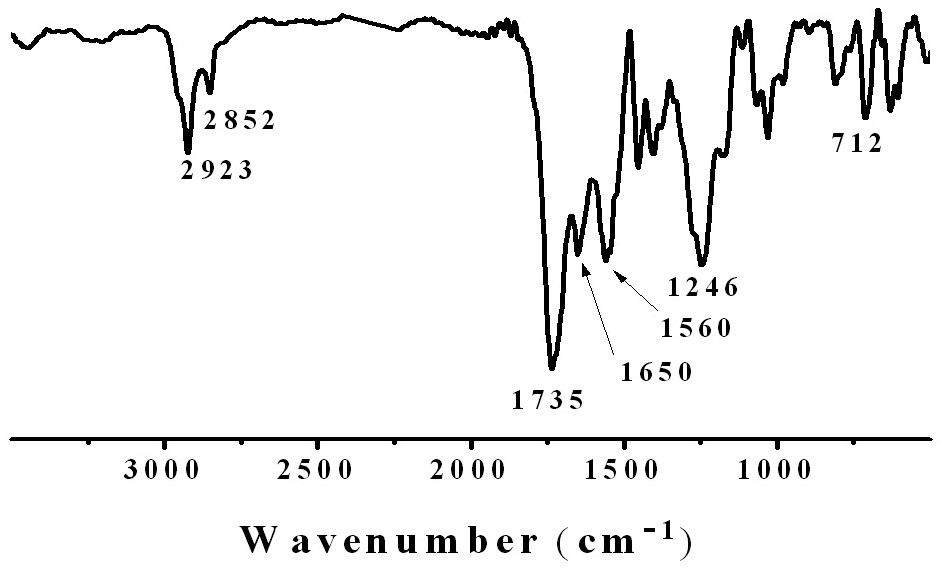

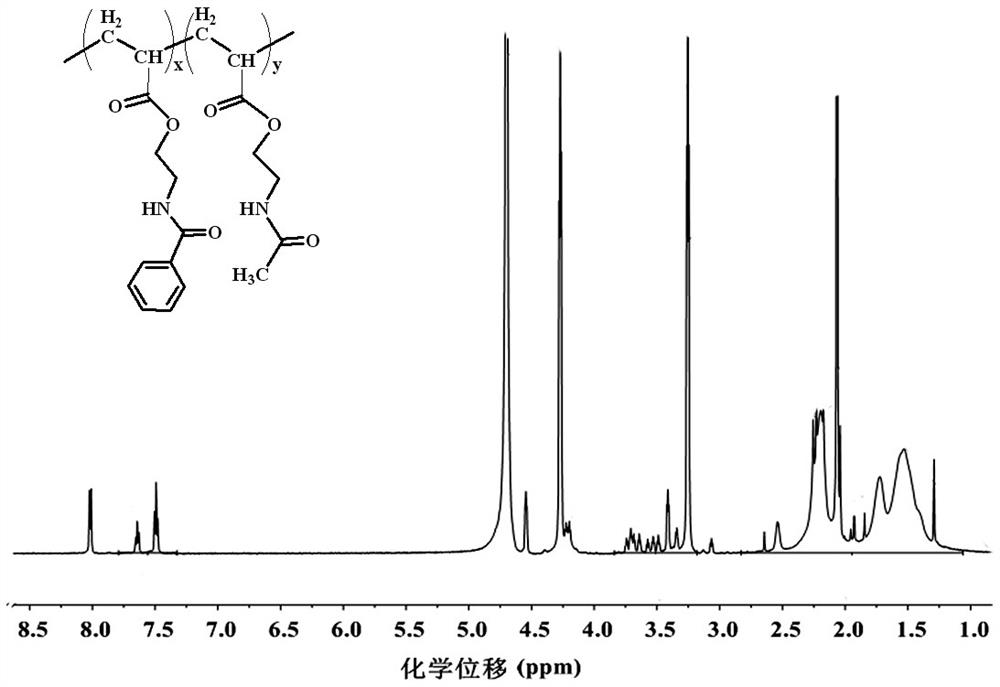

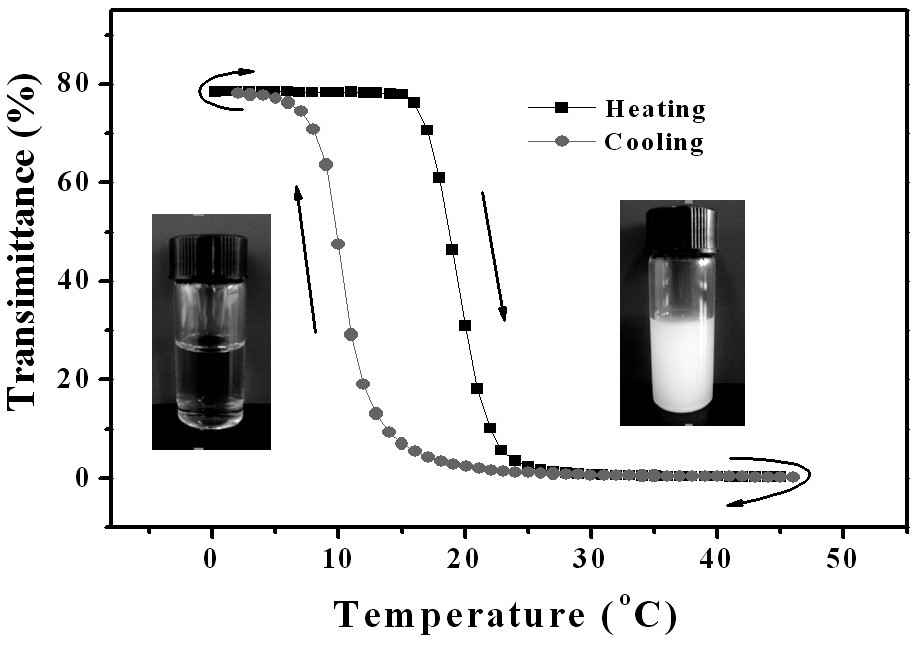

A temperature-sensitive poly(acetamidoethylacrylate-co-benzamidoethylacrylate) and its preparation method

A technology of benzamido ethyl acrylate and acetamido ethyl acrylate is applied in the field of polymers and their preparation, and achieves the effects of simple preparation method, good temperature-sensitive properties, and excellent temperature-sensitive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (a) Typical small molecule ring-opening reaction

[0039] In a 25 mL flask equipped with a magnet, add accurately weighed 0.720 g of acrylic acid monomer and 6 mL of absolute ethanol, and stir for 5 min to make the acrylic acid and ethanol mix evenly. Accurately weigh 0.6375 g of 2-methyl-2-oxazoline and 0.3675 g of 2-phenyl-2-oxazoline, add them into the flask, and stir at room temperature for 6 h to ensure that the ring-opening reaction is complete. Thin-layer chromatography (TLC) was used to observe whether the ring-opening reaction of oxazoline and acrylic acid monomer was complete or not with anhydrous ether as developing solvent.

[0040] (b) Free radical copolymerization reaction

[0041] After the reaction of the acrylic acid monomer is complete, accurately weigh 0.025 g of azobisisobutyronitrile (AIBN) and add it to the reaction flask, pump out the air in the flask and fill it with dry high-purity nitrogen, repeat 5 times to eliminate the oxygen in the air , ...

Embodiment 2

[0046] (a) Typical small molecule ring-opening reaction

[0047] In a 25 mL flask equipped with a magnet, add accurately weighed 0.720 g of acrylic acid monomer and 6 mL of absolute ethanol, and stir for 5 min to make the acrylic acid and ethanol mix evenly. Accurately weigh 0.680 g of 2-methyl-2-oxazoline and 0.294 g of 2-phenyl-2-oxazoline, add them into the flask, and stir at room temperature for 10 h to ensure that the ring-opening reaction is complete. Thin-layer chromatography (TLC) was used to observe whether the ring-opening reaction of oxazoline and acrylic acid monomer was complete or not with anhydrous ether as developing solvent.

[0048] (b) Free radical copolymerization reaction

[0049] After the reaction of the acrylic acid monomer is complete, accurately weigh 0.030 g of azobisisobutyronitrile (AIBN) and add it to the reaction flask, pump out the air in the flask and fill it with dry high-purity nitrogen, repeat 5 times to eliminate the oxygen in the air , t...

Embodiment 3

[0051] (a) Typical small molecule ring-opening reaction

[0052] In a 25 mL flask equipped with a magnet, add accurately weighed 0.720 g of acrylic acid monomer and 6 mL of anhydrous methanol, and stir for 5 min to make the acrylic acid and ethanol mix evenly. Accurately weigh 0.723 g of 2-methyl-2-oxazoline and 0.221 g of 2-phenyl-2-oxazoline, add them into the flask, and stir at room temperature for 8 h to ensure that the ring-opening reaction is complete. Thin-layer chromatography (TLC) was used to observe whether the ring-opening reaction of oxazoline and acrylic acid monomer was complete or not with anhydrous ether as developing solvent.

[0053] (b) Free radical copolymerization reaction

[0054] After the reaction of the acrylic acid monomer is complete, accurately weigh 0.0250 g of azobisisoheptanonitrile and add it to the reaction flask, extract the air in the flask and fill it with dry high-purity nitrogen, repeat 5 times to eliminate the oxygen in the air and preve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com