Process for producing nanometer bamboo carbon fiber by adopting polylactic acid group

A nano-bamboo charcoal fiber, polylactic acid-based technology, applied in the direction of melt spinning, single-component polyester rayon, etc., can solve the problems of high carbon emissions, shortage of petroleum product resources, and difficulty in degradation, and achieve production efficiency. Low energy consumption, significant environmental load characteristics, and resource-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

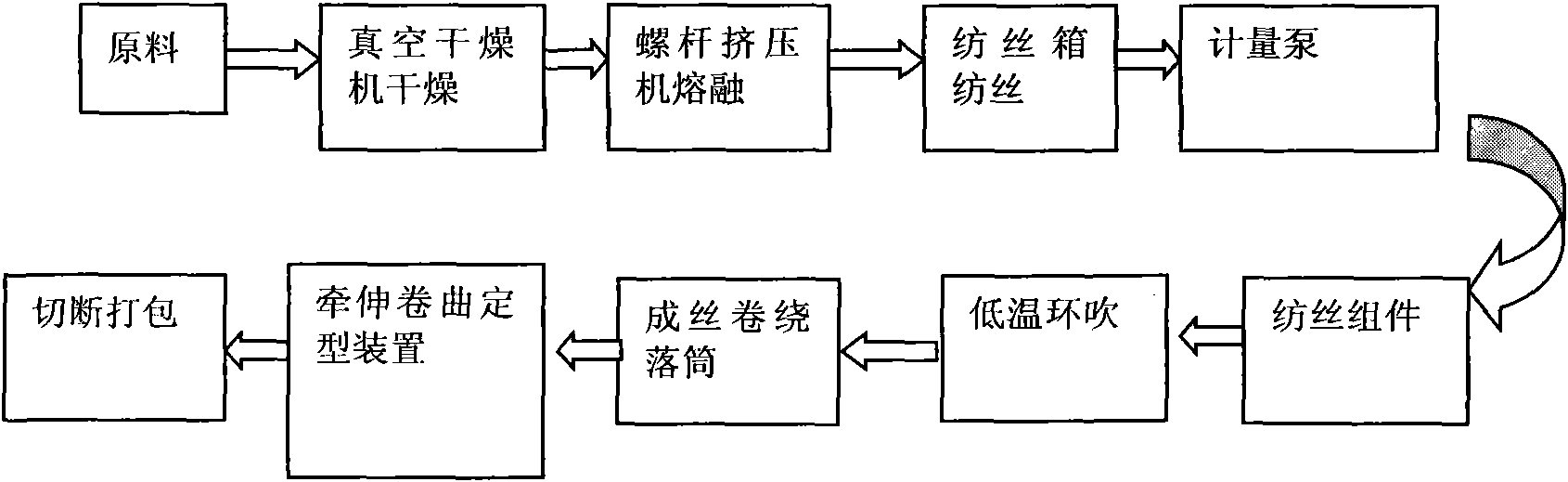

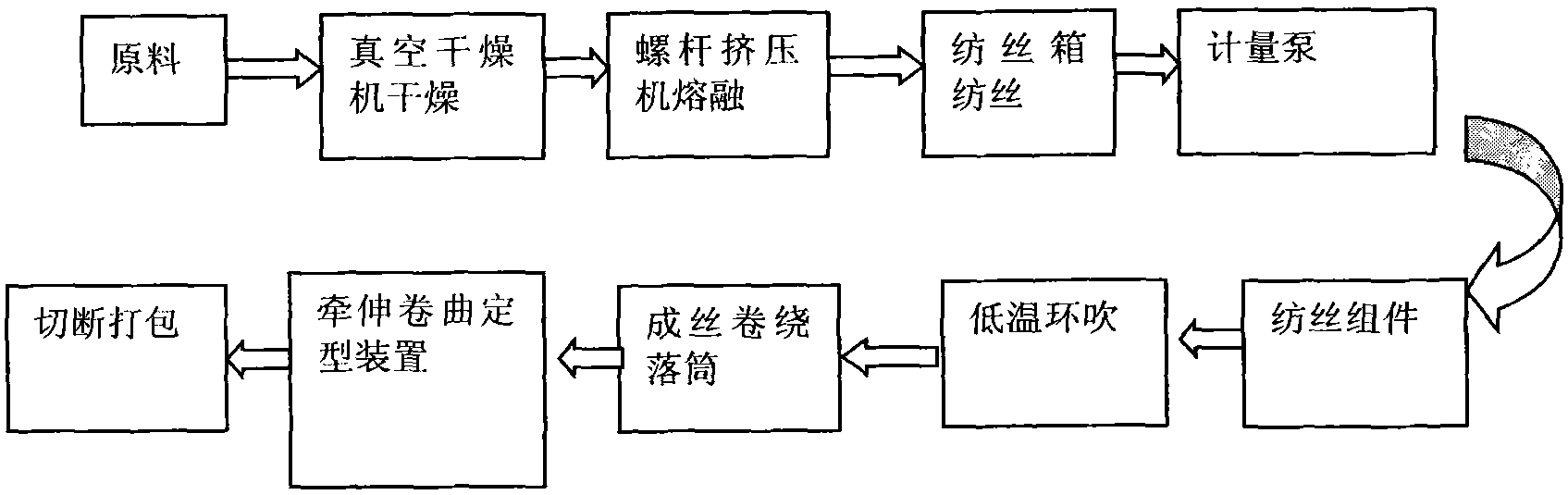

[0023] The technological method that adopts polylactic acid base to produce nano-bamboo charcoal fiber comprises the following technological steps:

[0024] (1) Selection of raw materials:

[0025] The polylactic acid chips used in the present invention are self-made by Anhui Hesheng Technology Co., Ltd., with a molecular weight of 335,000, a melting point of 162°C, a crystallinity of about 76%, a glass transition temperature of 58.5°C, and an L-isomer content of more than 99% of the slice molecules. The nano-bamboo charcoal powder is commercially available black 18000 order of Shanghai Ke Ruisen Environmental Protection Technology Co., Ltd., the specification of 100nm; Among the present invention, the mass ratio of polylactic acid slice and nano-bamboo charcoal powder is: polylactic acid slice 95%, nano-bamboo charcoal powder 5%.

[0026] (2), raw material mixing and drying:

[0027] The polylactic acid slices and nano-bamboo charcoal powder are mixed according to the ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com