Novel process for resource recycling of acid and alkali from high-salinity and high-hardness wastewater

A technology for recovering acid, alkali and high hardness, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc. Scaling and other problems, to achieve significant environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

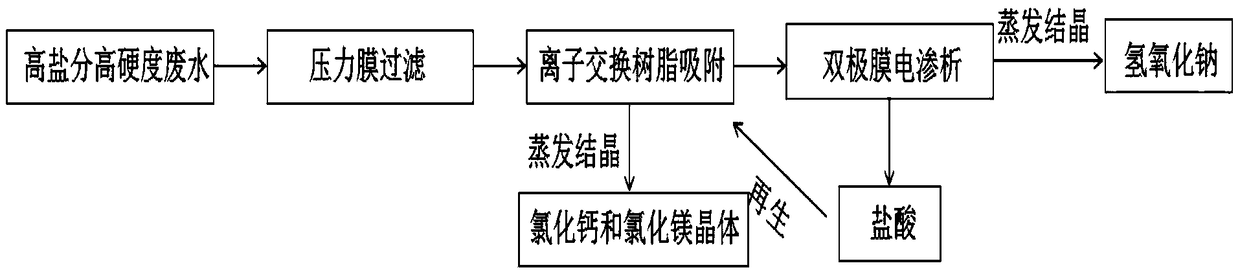

[0024] See attached figure 1 with attached figure 2 , technical scheme of the present invention comprises the following steps:

[0025] (1) The content of calcium ions in the high-salt and high-hardness wastewater used in the embodiment of the present invention is 2189 ppm, the content of magnesium ions is 1523 ppm, and the content of sodium ions is 2211 ppm. Pass the collected wastewater through the pressure membrane device, the ceramic membrane pore size is 20nm, the pressure used is between 2.0-6.0MPa, the flow rate is controlled at about 40L / h, and the suspended particles in the produced water are below 1ppm.

[0026] (2) Pass 20L of clarified waste water gained in step (1) into a 500mL CH-93 type cation exchange resin column, adjust the peristaltic pump flow rate 10BV / h, react for 4h, and take a sample to detect that the calcium ion content in the effluent is 65.67 ppm, the magnesium ion content is 30.46ppm, the calcium ion removal rate is 97%, and the magnesium ion re...

Embodiment 2

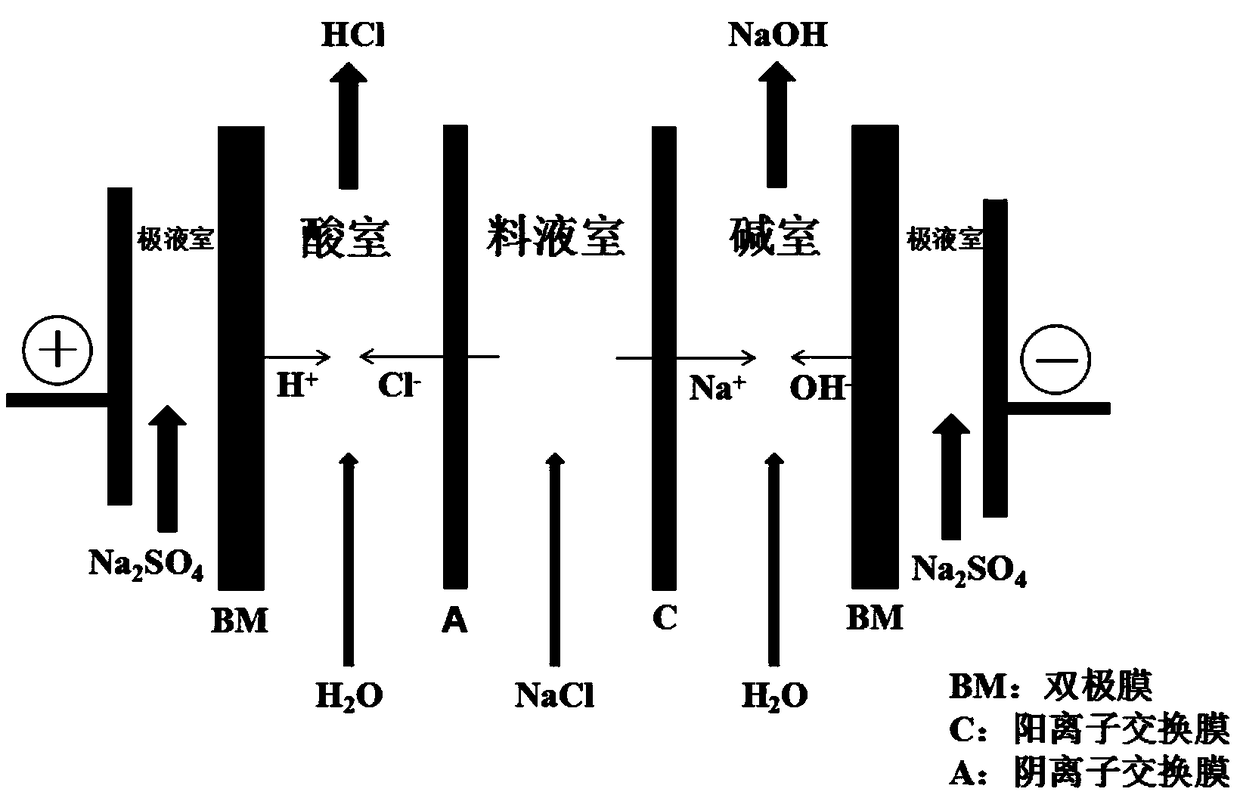

[0030] The operation of step (1), (2) and (4) is the same as embodiment 1, and the difference between step (3) and embodiment 1 is only: the membrane stack of each unit electrodialysis is composed of FBM / AHA / CMB / FBM, Adjust the voltage to 15V and react for 60 minutes. The acid chamber generates 5.90% hydrochloric acid, and the alkali chamber produces 4.80% sodium hydroxide solution. The current efficiency is 57.09%, and the energy consumption is 3.09kWh / kg.

Embodiment 3

[0032] The operation of step (1), (2) and (4) is the same as embodiment 1, and the difference between step (3) and embodiment 1 is only: the membrane stack of each unit electrodialysis is composed of FBM / AHA / CMB / FBM, Adjust the voltage to 20V and react for 50 minutes. The acid chamber generates 6.20% hydrochloric acid, and the alkali chamber produces 5.20% sodium hydroxide solution. The current efficiency is 60.43%, and the energy consumption is 3.47kWh / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com