A sleeve-type microchannel electrolytic reaction device and its application

An electrolytic reaction and channel technology, applied in electrolytic components, electrolytic processes, electrolytic organic production, etc., can solve the problems of low current efficiency of micro-electrolytic reaction devices, unfavorable environmental protection industrial production, and the burden of large-scale waste treatment, etc., to improve reaction conversion The effect of improving the efficiency, improving the stability of use, and reducing the three industrial wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

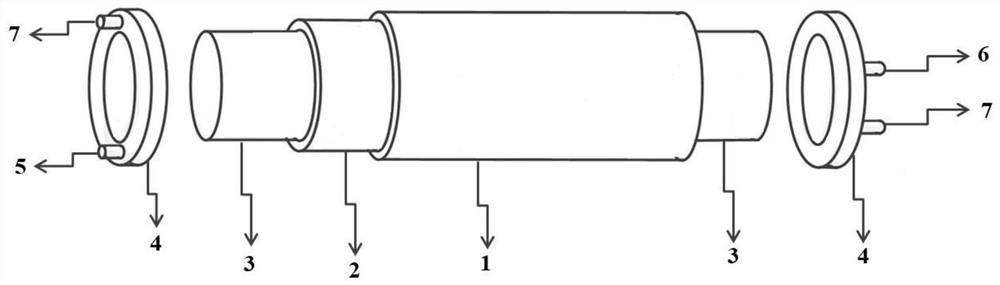

[0077] A casing type microchannel electrolysis reaction device, the structure schematic diagram is as follows figure 1 As shown, among them, 1 represents the outer tube electrode, 2 represents the insulating diaphragm, 3 represents the internal electrode, 4 represents the O-ring, 5 represents the feed pipe, 6 represents the discharge pipe, and 7 represents the wiring pile.

[0078] The inner diameter of the outer tube electrode is 6mm, and the outer diameter is 9mm, which is connected to the terminal through a wire; the thickness of the 0.2mm insulating diaphragm (polytetrafluoroethylene PTFE) is tightly wrapped on the outer diameter of the inner electrode surface of 5.5mm, The two are placed together in the outer tube electrode, so that the central axes of the outer tube electrode and the inner electrode coincide. At this time, the distance between the outer tube electrode and the inner electrode is 0.25mm; use an O-ring (PEEK ring) to connect the outer tube electrode It is f...

Embodiment 2

[0084] A sleeve-type microchannel electrolysis reaction device, which differs from Embodiment 1 only in that the inner electrode is an isostatic graphite rod with a diameter of 5.5 mm.

Embodiment 3

[0086] A sleeve-type microchannel electrolysis reaction device, the only difference from Example 1 is that the inner electrode is an isostatic graphite rod with a diameter of 5 mm, and the distance between the outer tube electrode and the inner electrode is 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com