A kind of preparation method of nano ruthenium carbon supported catalyst

A catalyst and carbon supported technology, applied in the field of catalysis, can solve the problems of low catalytic activity, easy loss of active components, low stability, etc., and achieve the effects of uniform particle size distribution, avoiding desorption and migration, and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

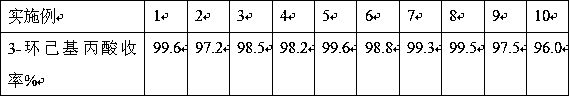

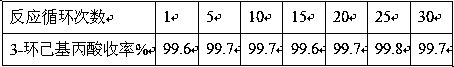

Examples

Embodiment 1

[0022] Accurately weigh 50.00 g of pretreated activated carbon, add it into 300 mL aqueous solution containing 5.56 g ruthenium trichloride hydrate, stir and impregnate for 3 h, and then use 1.0 mol L -1 Adjust the pH of the mixed slurry to 9 with sodium carbonate aqueous solution, continue to stir for 4 h, let it stand for 2 h, filter, wash the filter cake with water until it is neutral and free of chloride ions, and then transfer it to an oven for 4 h at 100 ° C. 2 The atmosphere was first calcined at 150 °C for 4 h, then at 400 °C for 4 h, and finally in H 2 :N 2 =1:9 (v / v) atmosphere at 300 ° C for 3 h, that is, a highly dispersed nano-ruthenium carbon-supported catalyst with a ruthenium loading of 4.0% was obtained.

Embodiment 2

[0024] Accurately weigh 50.00 g of pretreated activated carbon, add it into 300 mL aqueous solution containing 4.13 g of ruthenium trichloride hydrate, stir and impregnate for 3 h, and then use 1.0 mol L -1 Sodium carbonate aqueous solution adjusted the pH of the mixed slurry to 9, continued to stir for 4 h, let it stand for 1 h, filtered, washed the filter cake with water until it was neutral and free of chloride ions, then transferred to an oven for 4 h at 100 °C, and dried under N 2 The atmosphere was first calcined at 150 °C for 4 h, then at 400 °C for 4 h, and finally in H 2 :N 2 =1:9 (v / v) reduction at 300°C for 3 h, and a highly dispersed nano-ruthenium carbon-supported catalyst with a ruthenium loading of 3.0% was obtained.

Embodiment 3

[0026] Accurately weigh 50.00 g of pretreated activated carbon, add it into 300 mL aqueous solution containing 7.02 g of ruthenium trichloride hydrate, stir and impregnate for 3 h, and then use 1.0 mol L -1 Sodium carbonate aqueous solution adjusted the pH of the mixed slurry to 9, continued to stir for 4 hours, stood still for 1 hour, filtered, washed the filter cake with water until it was neutral and free of chloride ions, and then transferred to an oven for drying at 100°C for 6 hours. N 2 The atmosphere was first calcined at 150 °C for 4 h, then at 400 °C for 2 h, and finally in H 2 :N 2 =3:7 (v / v) atmosphere at 120 ℃ for 10 h to obtain a highly dispersed nano-ruthenium carbon-supported catalyst with a ruthenium loading of 5.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com