Method for preparing hexachlorobutadiene

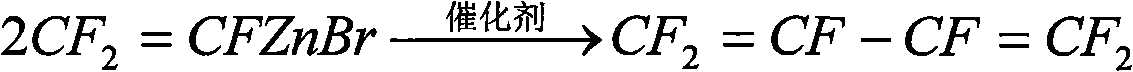

A technology of hexafluorobutadiene and trifluorovinyl zinc bromide, which is applied to the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of limiting the industrial production scale of hexafluorobutadiene, and achieve The synthetic route is short, the equipment requirements are not high, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: In a 250ml three-necked flask under nitrogen atmosphere, add 0.23mol of activated zinc powder with a particle size of 400 mesh, add 0.35mol of N-methylpyrrolidone (moisture content 34ppm), heat to 70°C, Add 0.10 mol of 1,1-dibromotetrafluoroethane dropwise, the dropping time is 1h, adjust the dropping speed, keep the reaction temperature lower than 90°C during the dropwise addition, keep the reaction at 90°C for 2.5h after the dropwise addition, and then drop to to room temperature.

[0035]The second step: the above-mentioned solution down to room temperature is added dropwise to a 500ml three-necked flask containing a solution of anhydrous ferric chloride (0.12mol) dissolved in N-methylpyrrolidone (0.40mol), and the dropping time lasts 1.5h. Control the rate of addition so that the reaction temperature does not exceed 40°C during the dropwise addition, and react at 40°C for 2.5 hours after the dropwise addition is completed. After the generated gas was conden...

Embodiment 2

[0037] Step 1: In a 250ml three-necked flask under nitrogen atmosphere, add 0.23mol of activated zinc powder with a particle size of 450 mesh, add 0.40mol of N-methylpyrrolidone (moisture content 169ppm), heat to 70°C, Add 0.1 mol of 1,1-dibromotetrafluoroethane dropwise, the time for the dropwise addition is 1.5h, adjust the dropping speed, the reaction temperature cannot exceed 90°C during the dropwise addition, keep the reaction at 90°C for 6h after the dropwise addition, and then Bring to room temperature.

[0038] The second step: under stirring, add the above solution dropwise to a 500ml three-necked flask containing a solution of anhydrous ferric chloride (0.14mol) dissolved in N-methylpyrrolidone (0.35mol) at 15°C, and the dropping time is 1.2 h, after the dropwise addition, reacted at 20°C for 4h; the generated gas was condensed at -30°C, and collected with liquid nitrogen as a cold trap. The actual collection obtained 4.70g of liquid, and the actual yield of hexafluo...

Embodiment 3

[0040] Step 1: In a 250ml three-necked flask under nitrogen atmosphere, add 0.2mol of activated zinc powder, the particle size of which is 400 mesh, and 0.30mol of N-methylpyrrolidone (moisture content: 70ppm), heat to 60°C, drop Add 0.1mol of 1,1-dibromotetrafluoroethane, the dropping time is 0.8h, adjust the dropping speed, keep the reaction temperature at 80-90°C during the dropping process, and keep the reaction at 90°C for 3.0h after the dropping is completed , and then cooled to room temperature.

[0041] The second step: the above-mentioned solution cooled to room temperature was added dropwise to a 500ml three-necked flask containing anhydrous copper bromide (0.42mol) dissolved in N-methylpyrrolidone (1.20mol), and the dropwise addition lasted 1.5h, controlled The rate of addition is such that the reaction temperature during the dropping process does not exceed 30°C. After the dropwise addition, react at 30°C for 3 hours. After the generated gas is condensed at -30°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com