Separation and purification method of mixed waste gas containing chlorine and hydrogen chloride

A purification method and technology of hydrogen chloride gas, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of low economic value of treatment and recovery, complicated equipment, long treatment process, etc., and achieve low cost, low treatment cost, The effect of obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

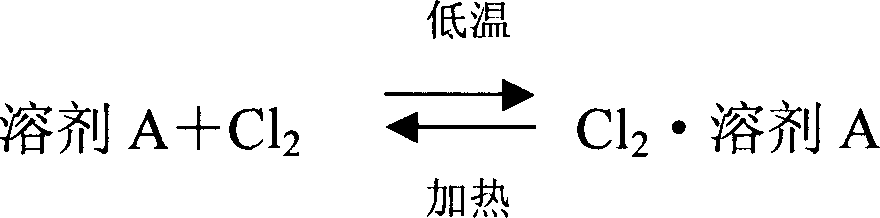

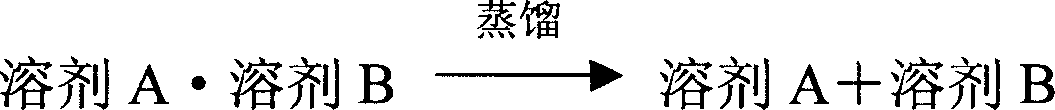

Method used

Image

Examples

Embodiment 1

[0038]The separation and purification device of the present invention is mainly composed of the following equipment: a chlorine gas absorption tower, which is a packed tower made of carbon steel and filled with Raschig ring packing made of carbon steel. Waste gas enters from the bottom of the tower, and the absorbed gas escapes from the top of the tower. The solvent A cooled by the condenser is sprayed from the upper part of the tower and contacted with the exhaust gas countercurrently, and the absorbed liquid enters the circulation tank from the bottom of the tower; the chlorine gas desorption tower is a packed tower made of carbon steel, and the upper part of the tower body It is a shell and tube condenser with a carbon steel Raschig ring packing in the middle. The gas phase heated by the desorption kettle enters the lower part of the desorption tower. After desorption, the gas escapes from the top of the tower, and the solvent A after absorbing chlorine is sprayed from the mi...

Embodiment 2

[0041] The mixed waste gas containing chlorine and hydrogen chloride is composed of: 80% by weight of hydrogen chloride, 19.8% by weight of chlorine gas, and 0.2% by weight of organic matter. In the packed absorption tower, carbon tetrachloride solvent is used to absorb chlorine in the waste gas, and the addition of solvent carbon tetrachloride The amount is 10% excess after ensuring that all the chlorine in the mixed exhaust gas is absorbed, and the absorption temperature is less than 15°C. After absorbing the chlorine gas, the carbon tetrachloride solvent is heated to 70°C in the desorption tower to desorb the chlorine gas to obtain chlorine gas with a purity of 99%, and the chlorine gas can be returned to the system for recycling. The mixed gas of hydrogen chloride gas and carbon tetrachloride solvent that escapes from the top of the tower is further removed in the secondary packing absorption tower with hexachlorobutadiene solvent in the mixed gas of carbon tetrachloride so...

Embodiment 3

[0043] The mixed waste gas containing chlorine and hydrogen chloride is composed of: 50% by weight of hydrogen chloride, 49.5% by weight of chlorine, and 0.5% by weight of organic matter. The chlorine in the waste gas is absorbed by benzene solvent in the packed absorption tower, and the amount of solvent benzene is ensured in the mixed waste gas. After all the chlorine gas is absorbed, the excess is 10%, and the absorption temperature is less than 15°C. The benzene solvent after absorbing chlorine gas is heated to 75°C in the desorption tower to desorb chlorine gas to obtain chlorine gas with a purity of 99%, which can be returned to the system for recycling. The mixed gas of hydrogen chloride gas and benzene solvent escaped from the top of the tower is further removed by the hexachlorobutadiene solvent in the secondary packed absorption tower to remove the benzene solvent in the mixed gas, and the hydrogen chloride gas after preliminary purification is removed by washing with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com