Patents

Literature

73 results about "Chlorine production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

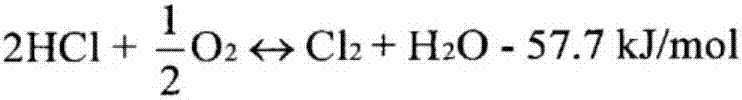

This article presents the industrial and laboratory methods to prepare elemental chlorine.

Method for refining byproduct hydrogen chloride during production process of organochlorine products

InactiveCN101200286AHigh economic valueLarge adsorption capacityChlorine/hydrogen-chloride purificationDispersed particle separationBenzeneDesorption

The utility model relates to a refining method of by-product HCl gas in organic chlorine production process, the by-product HCl gas passes by the absorption post filled with absorption resin at flow speed of 0.1-0.5m / s under constant-temperature constant-pressure, the removal ratio of the organic in the HCl gas can reach 99.8 percent, afterwards the absorption resin that absorbs the organic is desorbed by 110-160 DEG C saturation vapor, the desorption ratio can exceed more than 99 percent, the desorption liquid is condensed, oil-gas separated, recycled to obtain the organic mixture containing benzene or chlorobezene, the mixture is furthermore distilled and separated to obtain the benzene or chlorobezene, finally the absorption resin after desorbed by the vapor is dried by 110-140 DEG C hot air, and then cooled to room temperature for next stage absorption. The absorption resin can be reused after desorption and regeneration.

Owner:NANJING UNIV +1

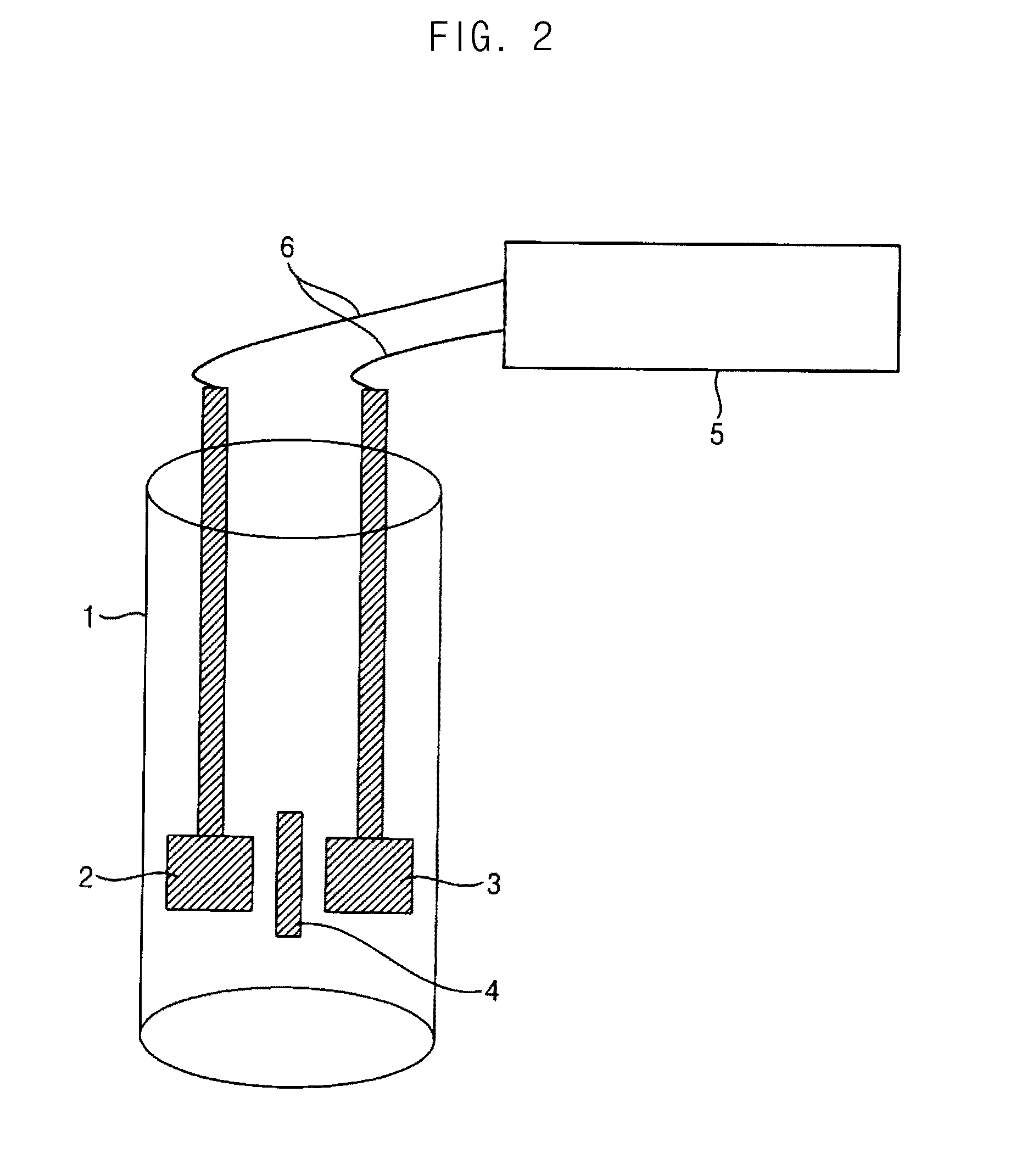

Electrode for electrolysis cell

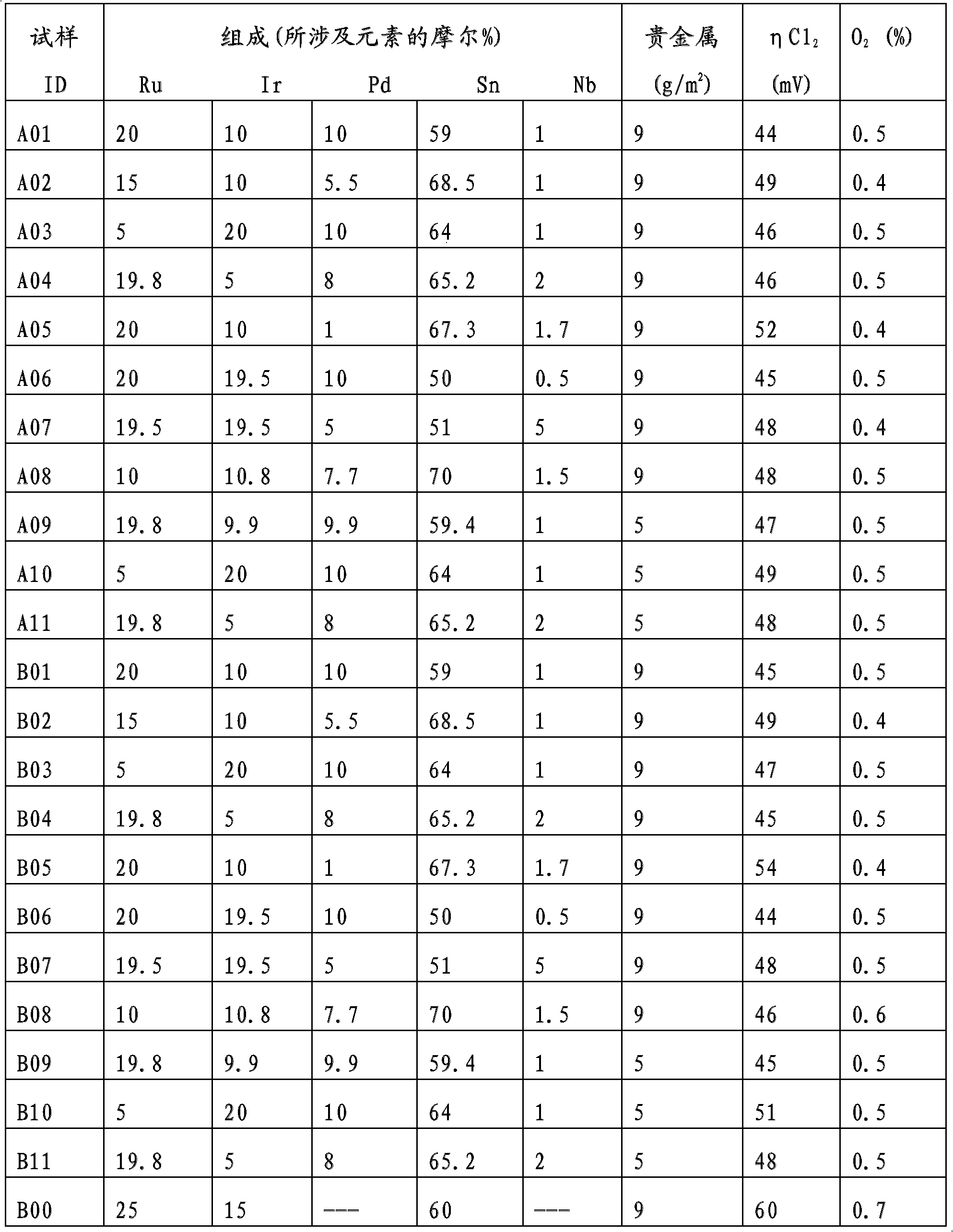

The invention relates to an electrode formulation comprising a catalytic layer containing tin, ruthenium, iridium, palladium and niobium oxides applied to a titanium or other valve metal substrate. A protective layer based on titanium oxide modified with oxides of other elements such as tantalum, niobium or bismuth may be interposed between the substrate and the catalytic layer. The thus obtained electrode is suitable for use as anode in electrolysis cells for chlorine production.

Owner:IND DE NORA SPA

Methods of producing hydrochloric acid from hydrogen gas and chlorine gas

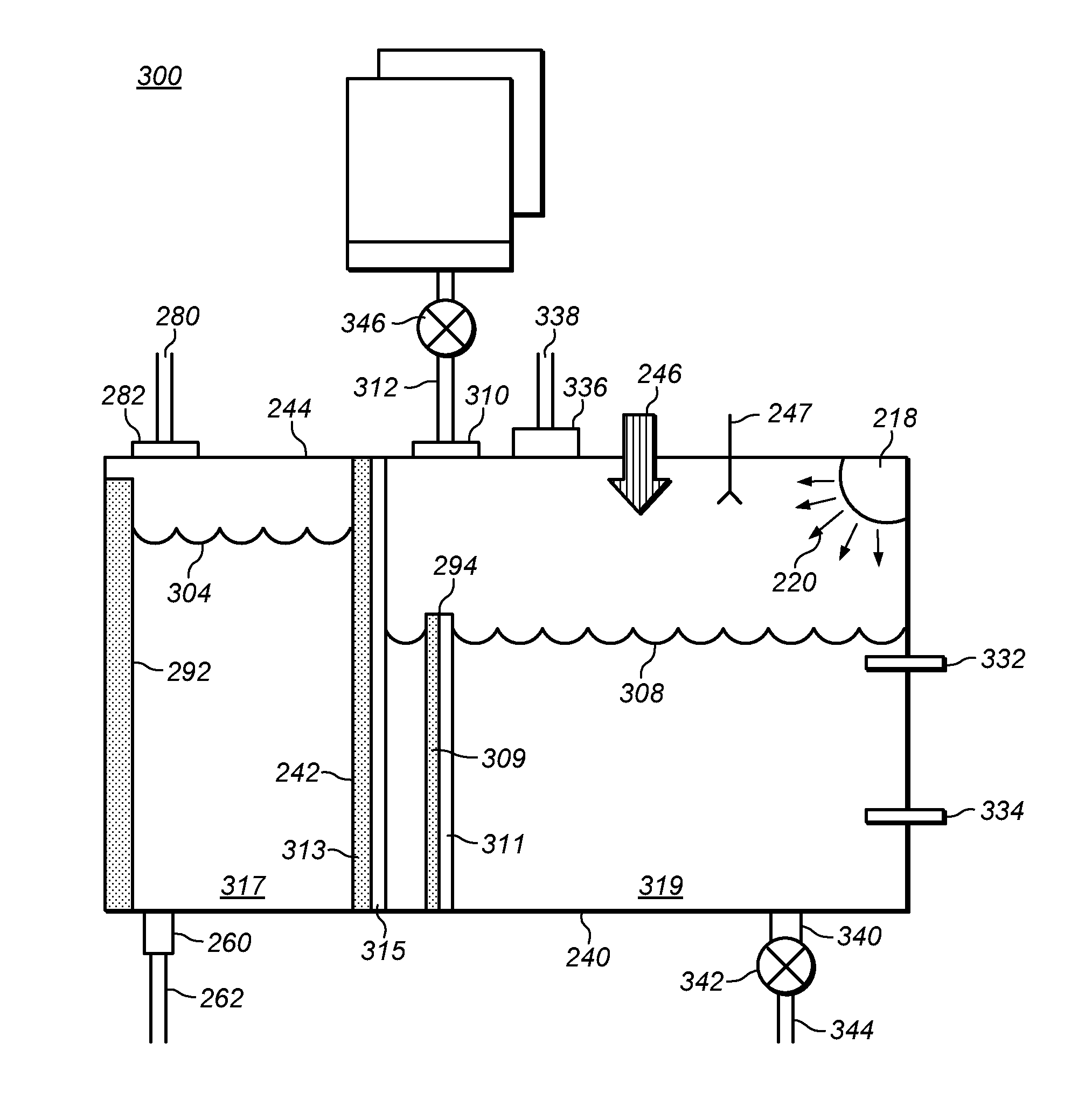

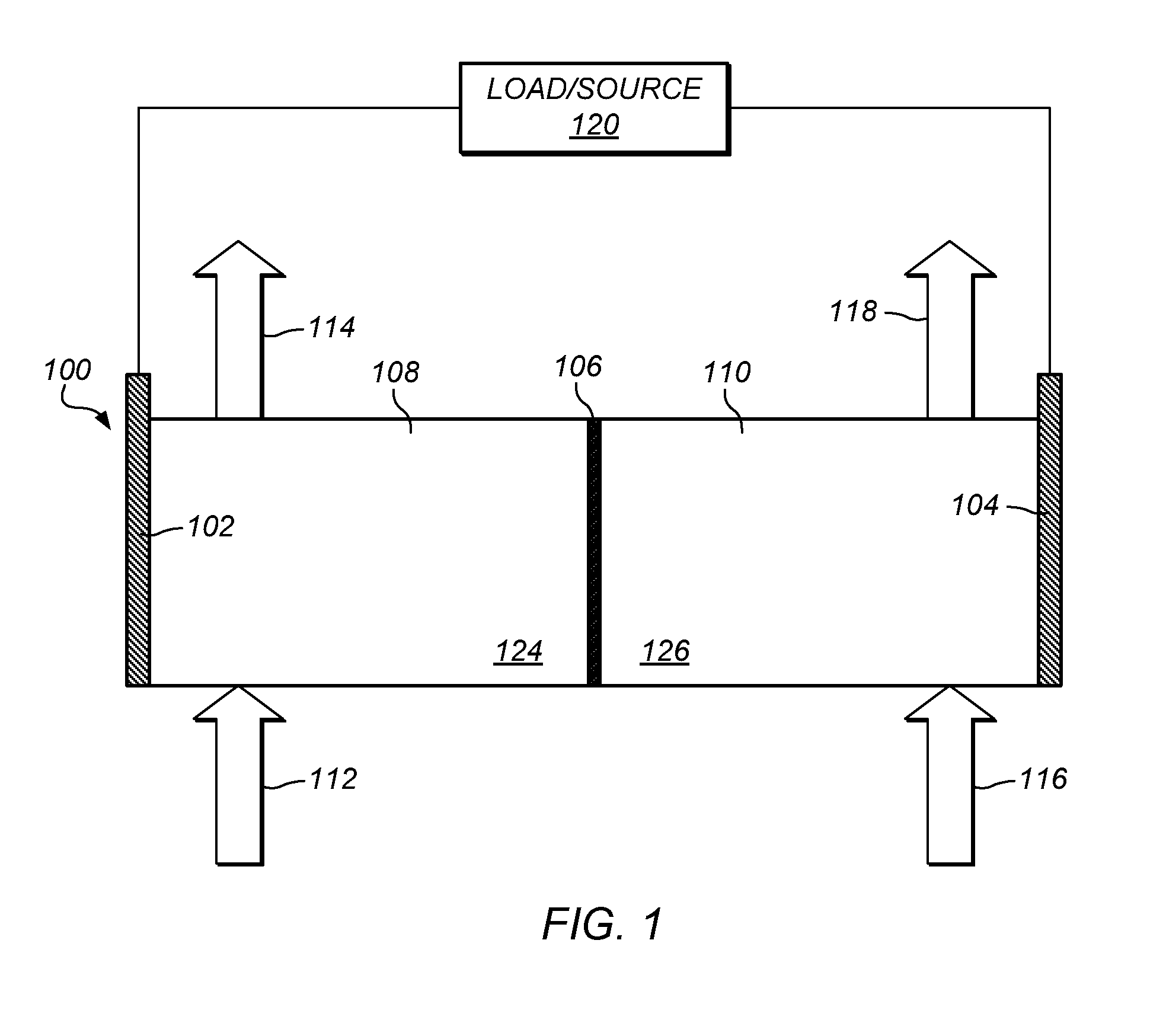

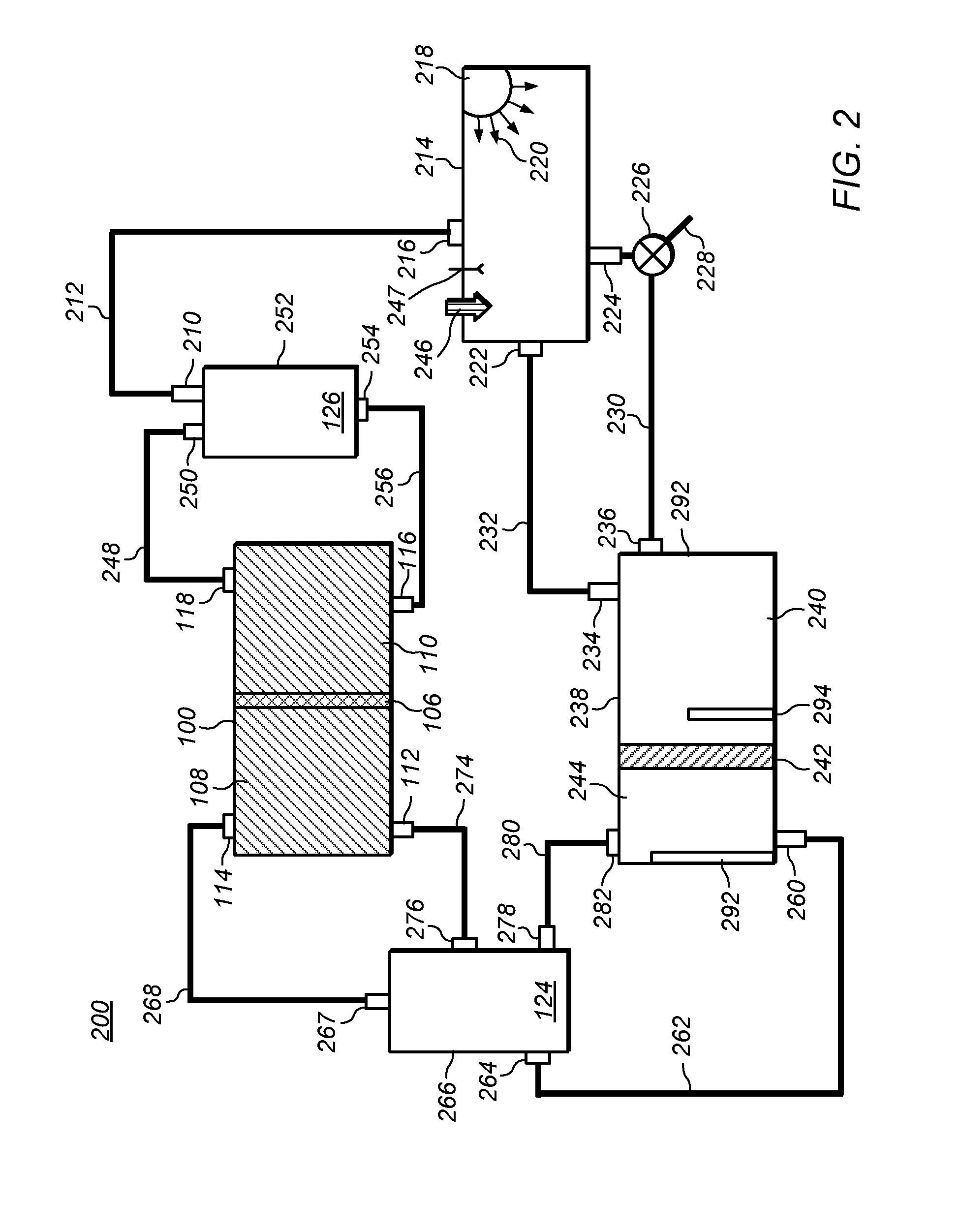

A method of producing HCl from H2 and Cl2 is provided. In some embodiments, the method comprises at least one photochemical chamber placed in fluid communication with at least one source of H2 and at least one source of Cl2. In some embodiments, the photochemical chamber effects the formation of HCl through the use of at least one source of ultraviolet radiation contained therein. In some embodiments, the HCl product may be captured and used as a gas. In some embodiments, the HCl product may be absorbed into water to form an aqueous HCl solution.

Owner:IMERGY POWER SYST

Catalyst and production process thereof, and chlorine production using the catalyst

ActiveUS20100196255A1High activityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRare earthChlorine production

A catalyst has high activity and is suitable for use in producing chlorine by oxidizing hydrogen chloride with oxygen. The catalyst includes copper, an alkali metal and a rare earth and has pores of which pores having a diameter of 5 to 15 nm have a pore volume of 0.4 to 2.0 ml / g.

Owner:MITSUI CHEM INC

Electrode for Electrolysis Cell

The invention relates to an electrode formulation comprising a catalytic layer containing tin, ruthenium, iridium, palladium and niobium oxides applied to a titanium or other valve metal substrate. A protective layer based on titanium oxide modified with oxides of other elements such as tantalum, niobium or bismuth may be interposed between the substrate and the catalytic layer. The thus obtained electrode is suitable for use as an anode in electrolysis cells for chlorine production.

Owner:IND DE NORA SPA

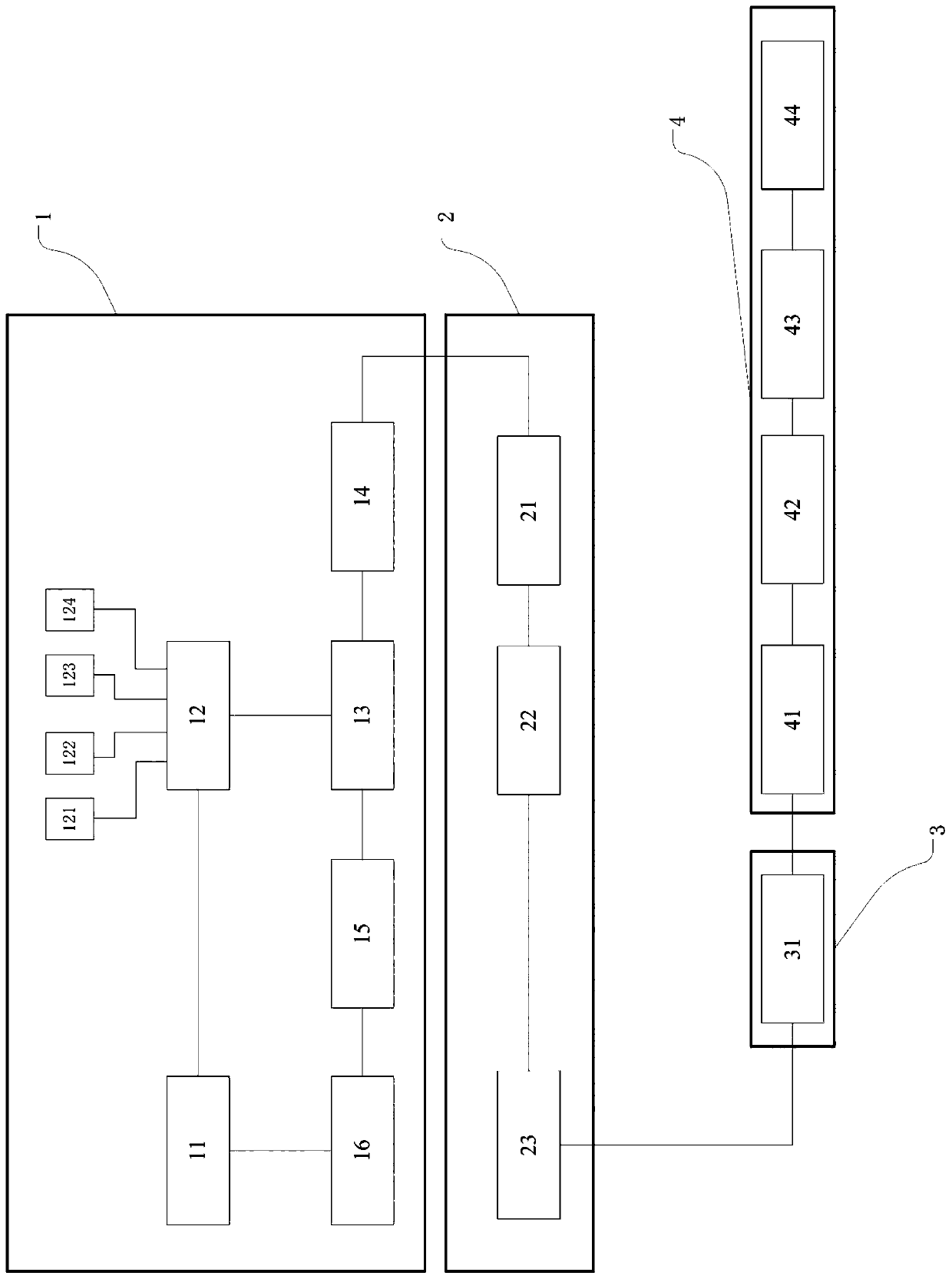

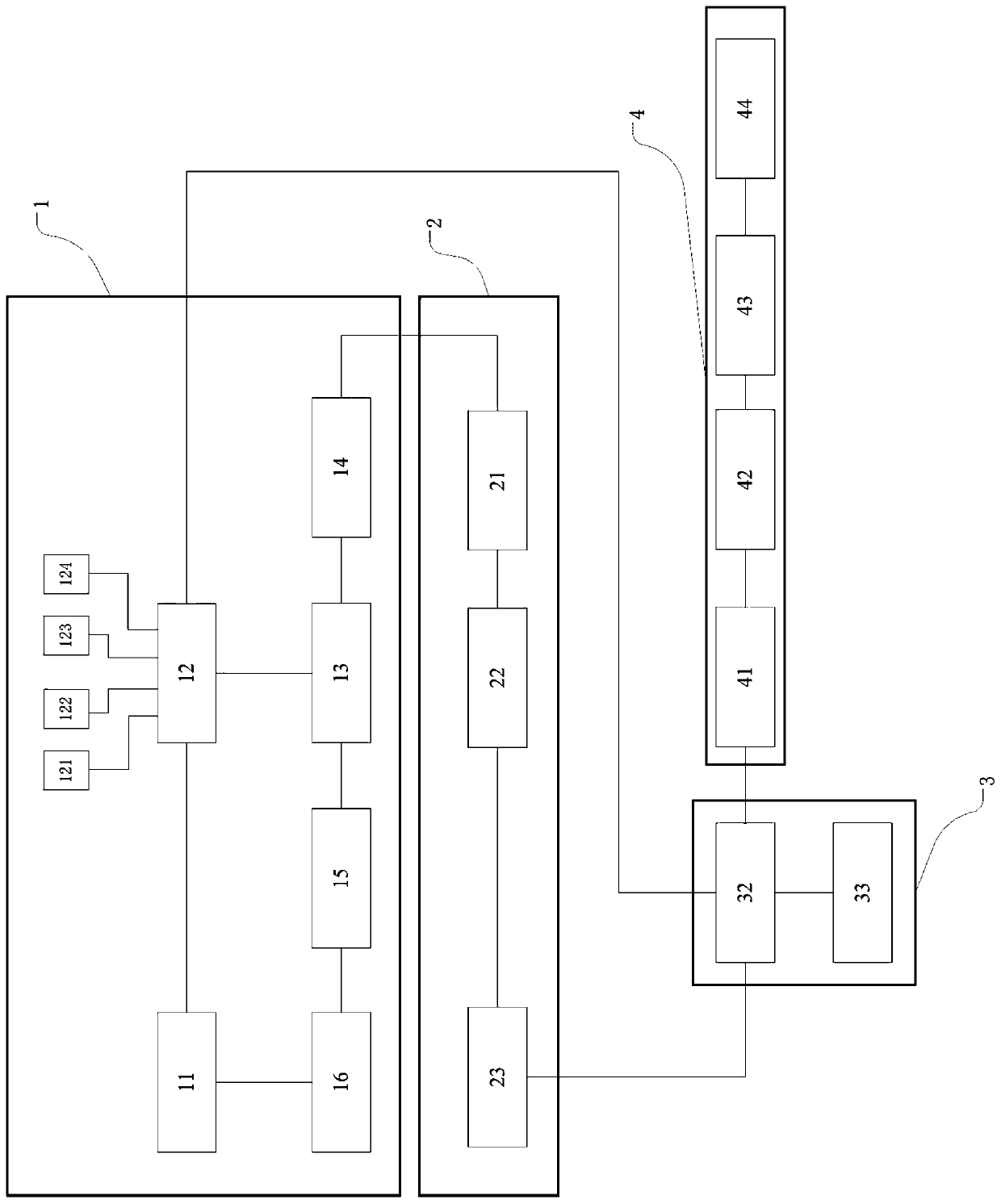

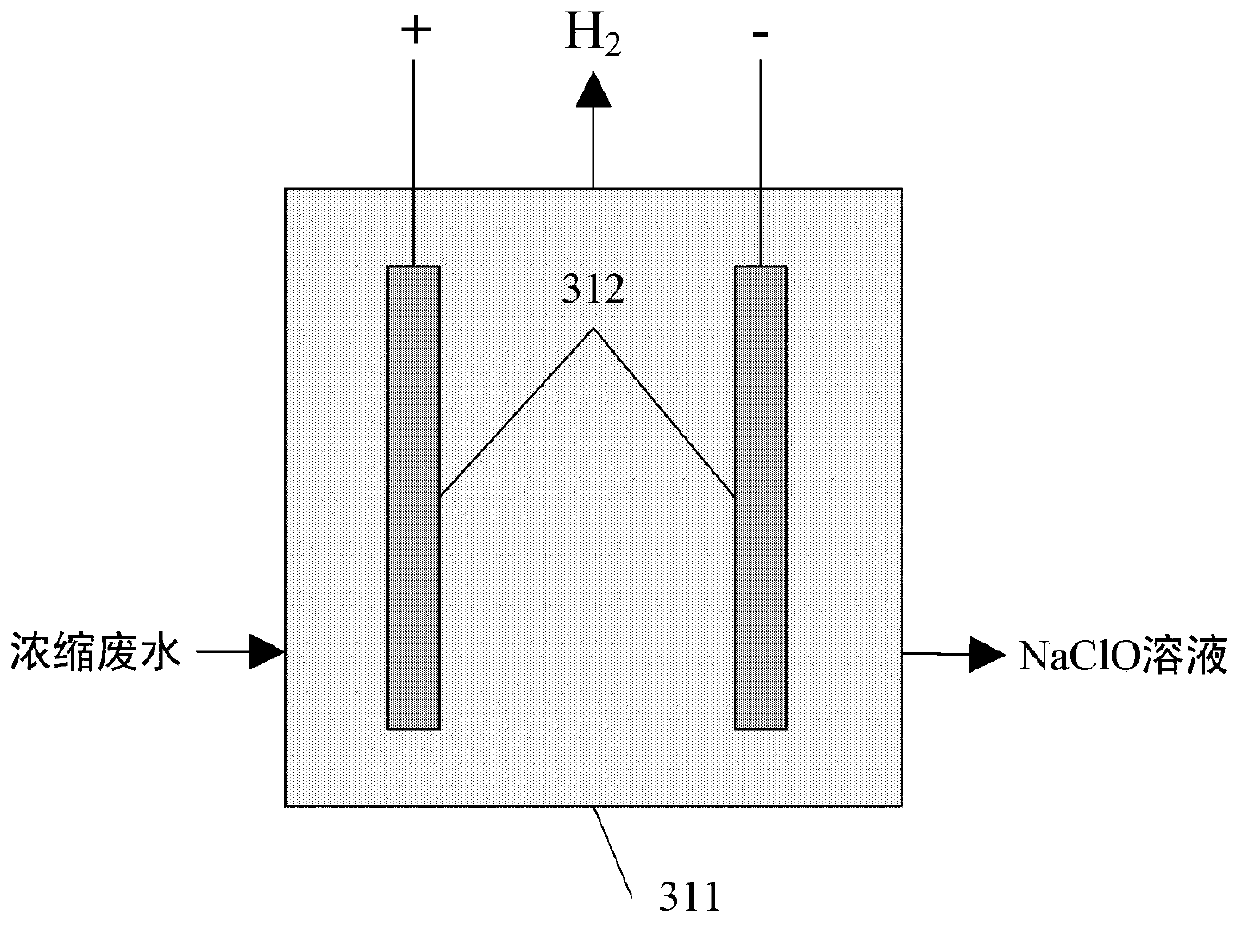

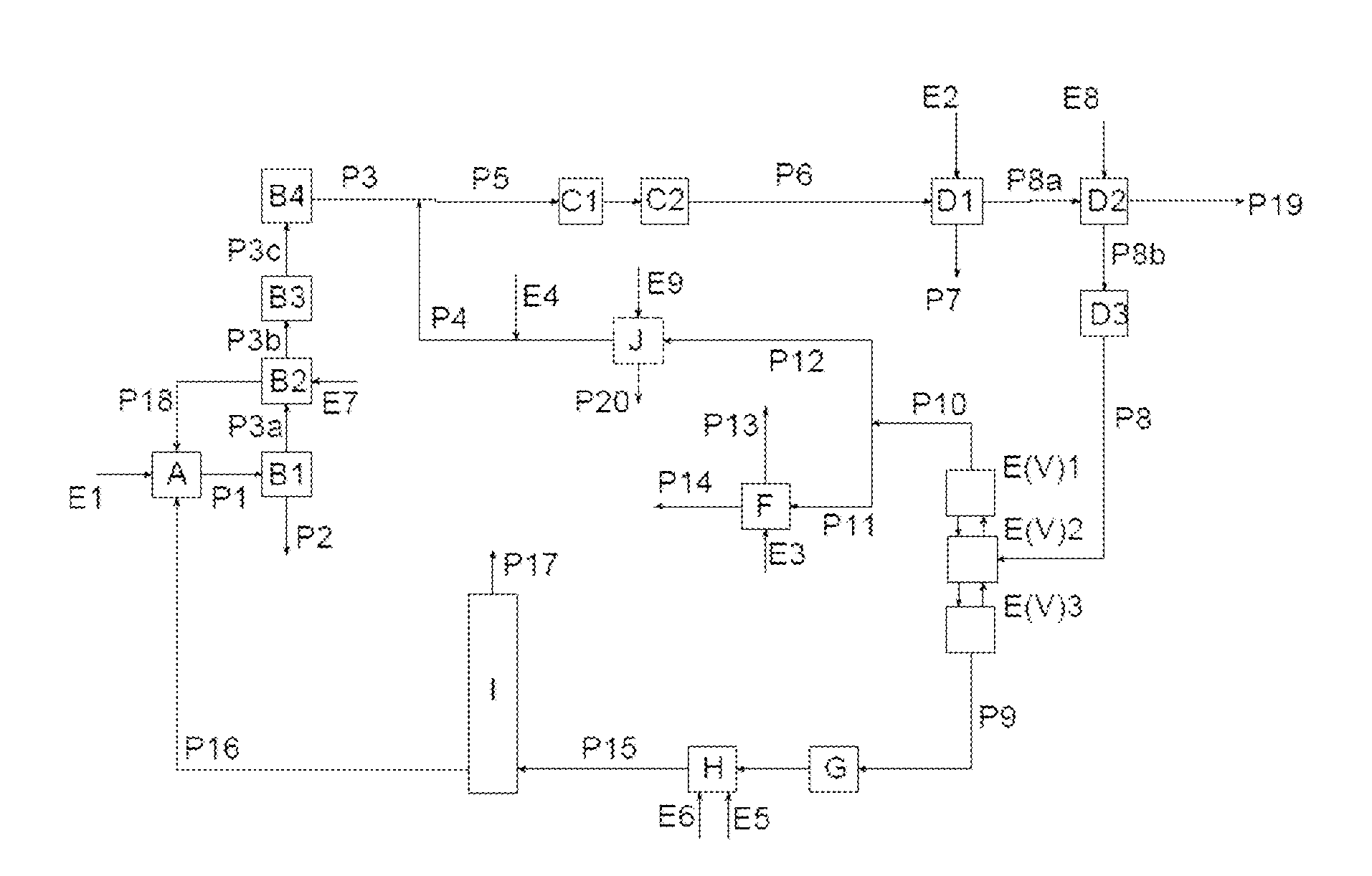

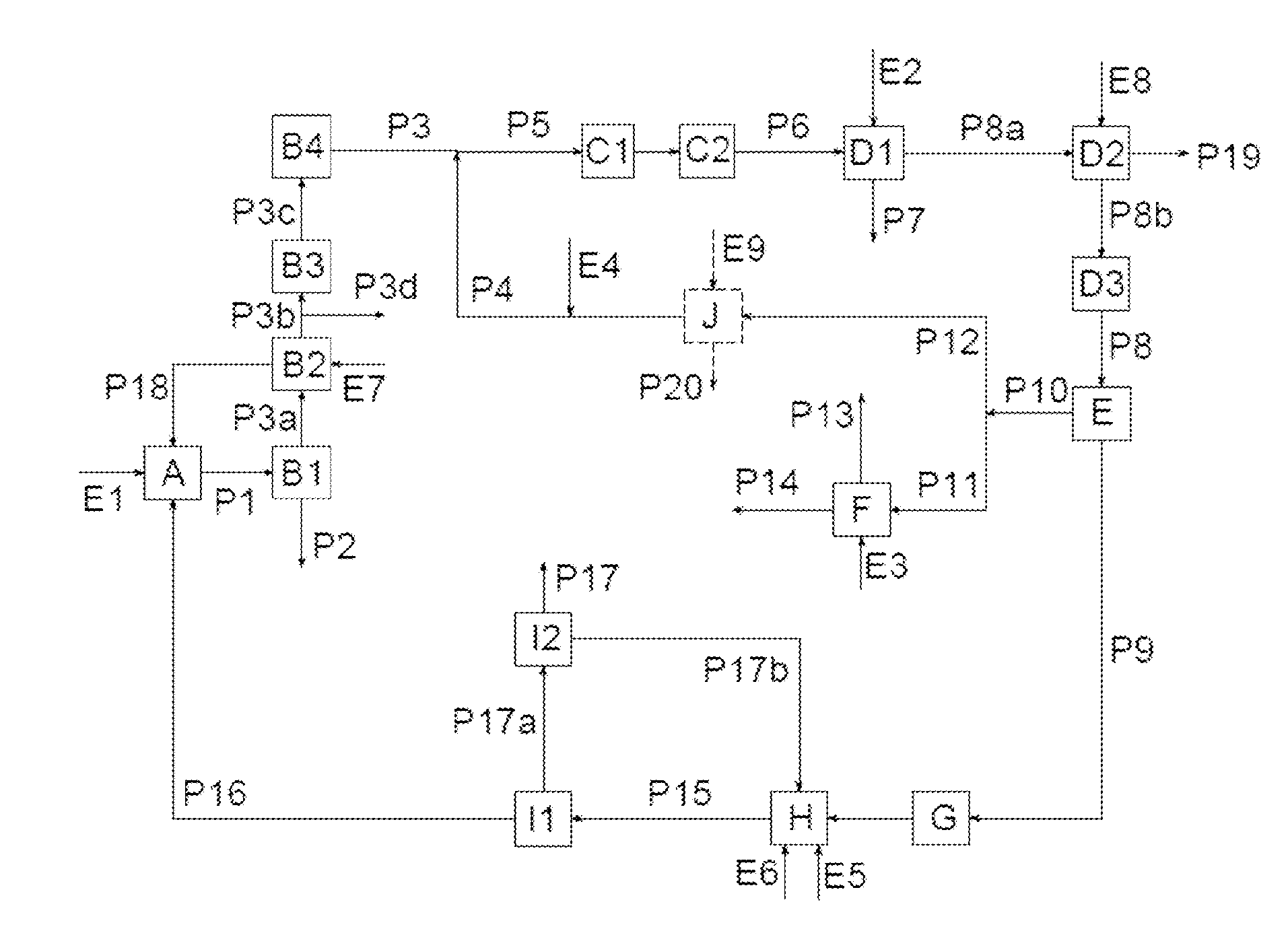

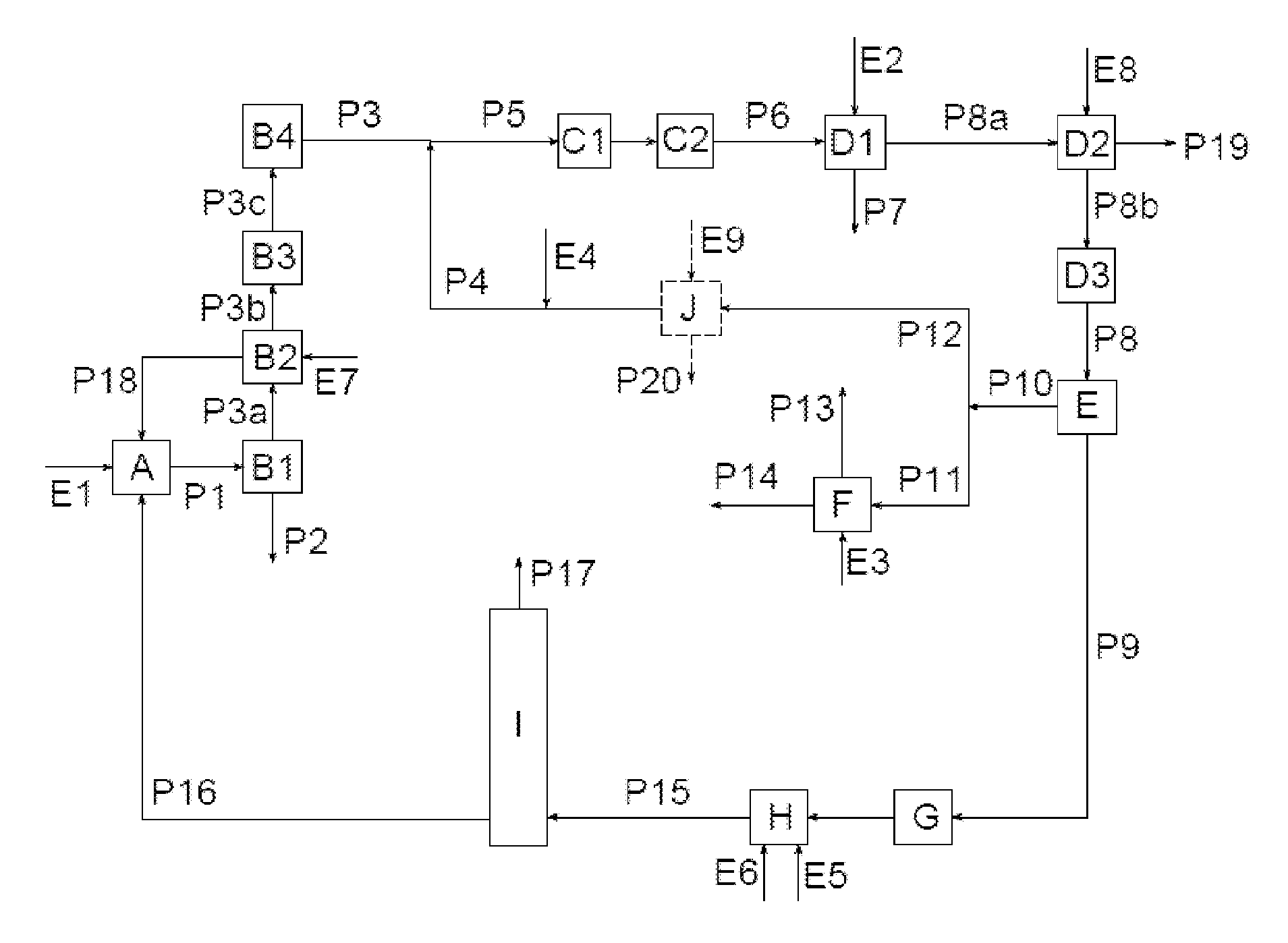

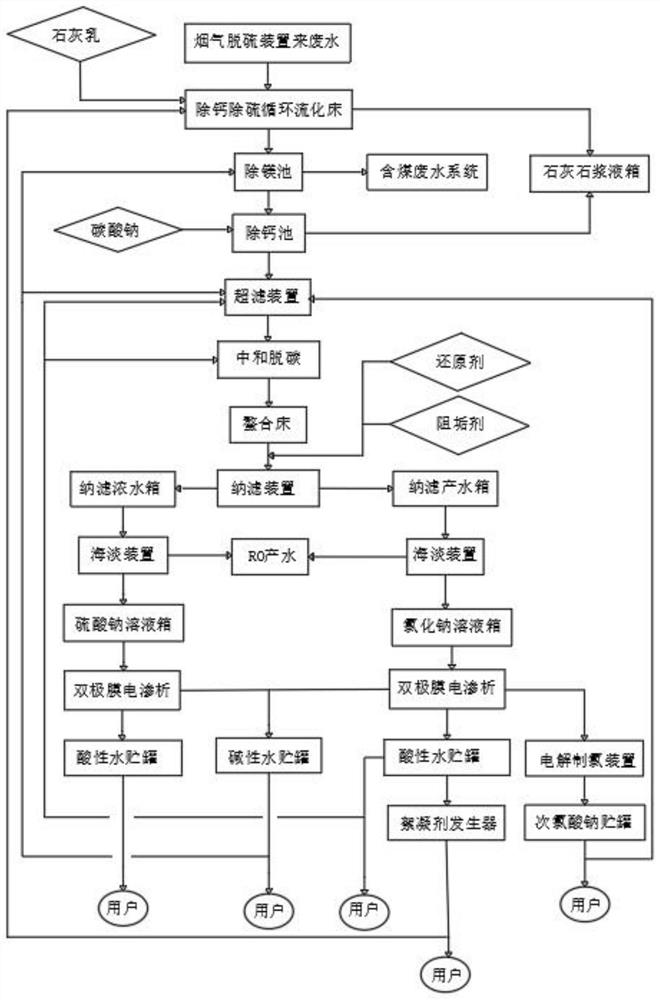

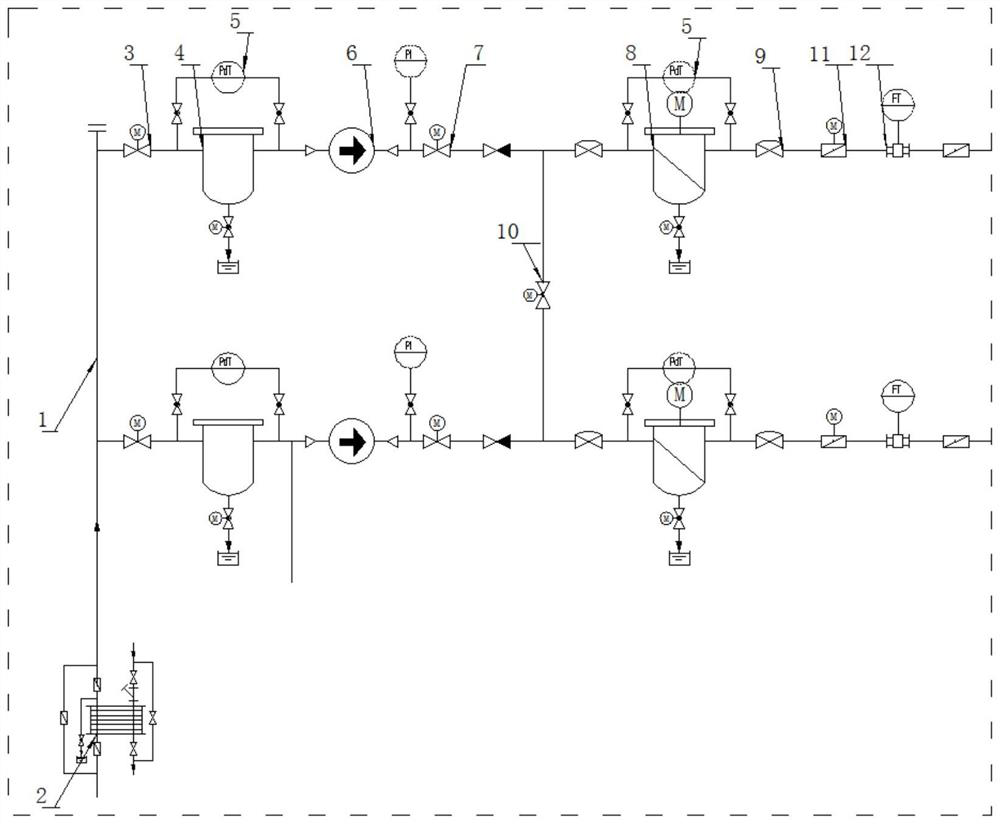

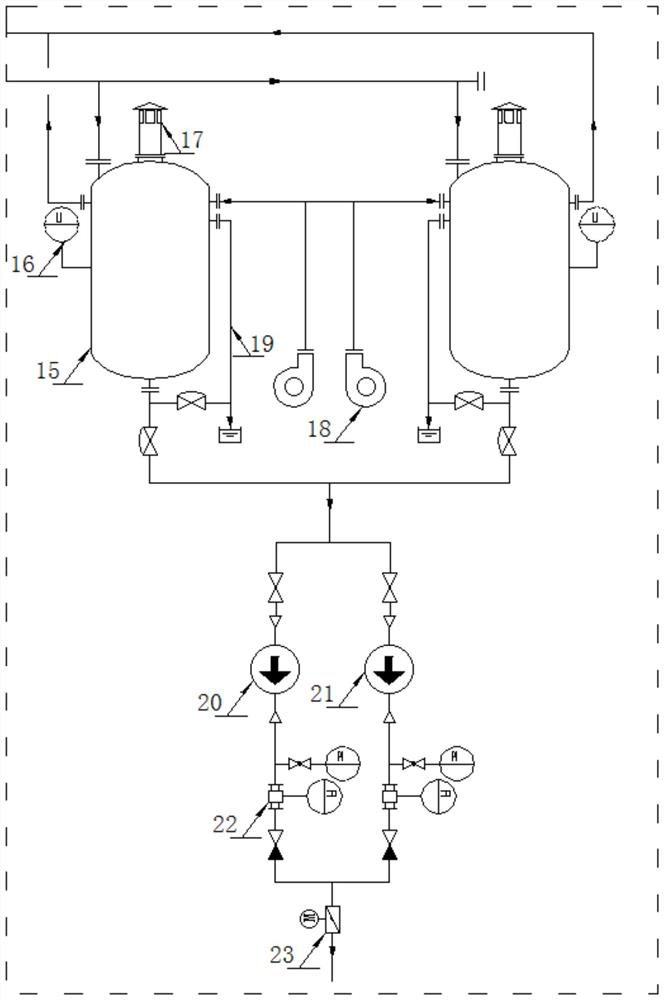

Desulfurization wastewater treatment system and method

InactiveCN109851137AImprove processing efficiencySave resource costSludge treatment by de-watering/drying/thickeningWater contaminantsEthyl ChlorideElectric generator

The invention provides a desulfurization wastewater treatment system. The system comprises a softening pretreatment unit, a membrane salt-separation concentration unit and an electrolytic chlorine-production unit, wherein the softening pretreatment unit is used to remove hardness, solid suspended matters and heavy metal ions in a desulfurization wastewater; the membrane salt-separation concentration unit is used to carry out monovalent salt and divalent salt separation and deep concentration separation on the wastewater subjected to the softening pretreatment unit; and the electrolytic chlorine-production unit is used to carry out electrolytic chlorine production on the concentrated wastewater produced by the membrane salt-concentration unit. The system can further comprise a hydrogen purification and recovery unit, and the hydrogen purification and recovery unit comprises a chlorine removal apparatus, a water removal apparatus, a deoxidization apparatus and a pressure-swing temperature-changing adsorption apparatus, high purity hydrogen gas is generated and transported to a hydrogen cooling system of an electric generator. On the basis of realizing zero discharge, products of eachlink are rationally treated and recycled according to the technical scheme of the system, the wastewater treatment efficiency is improved, the resource cost is reduced, and the purpose of resource comprehensive utilization of the desulfurization wastewater is achieved.

Owner:GUODIAN NEW ENERGY TECH INST +1

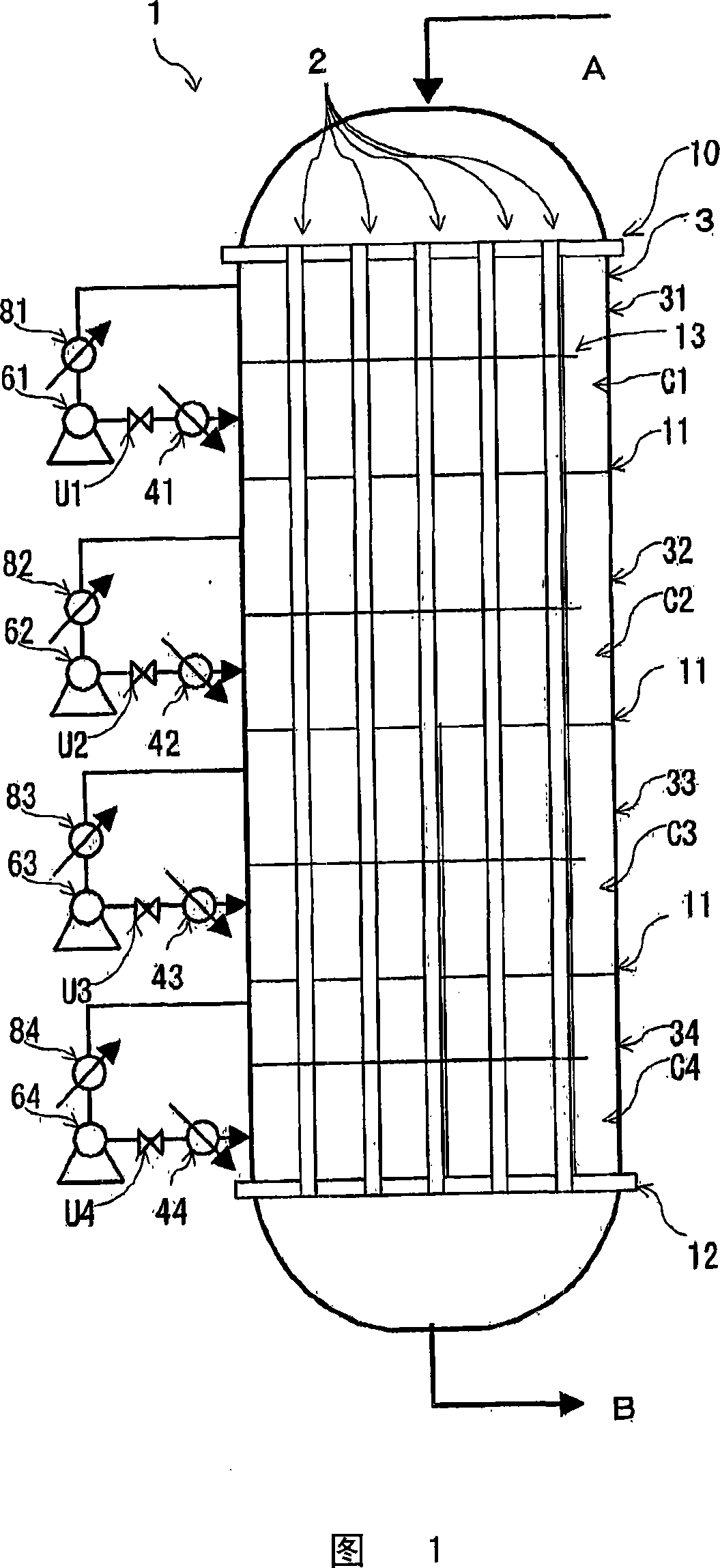

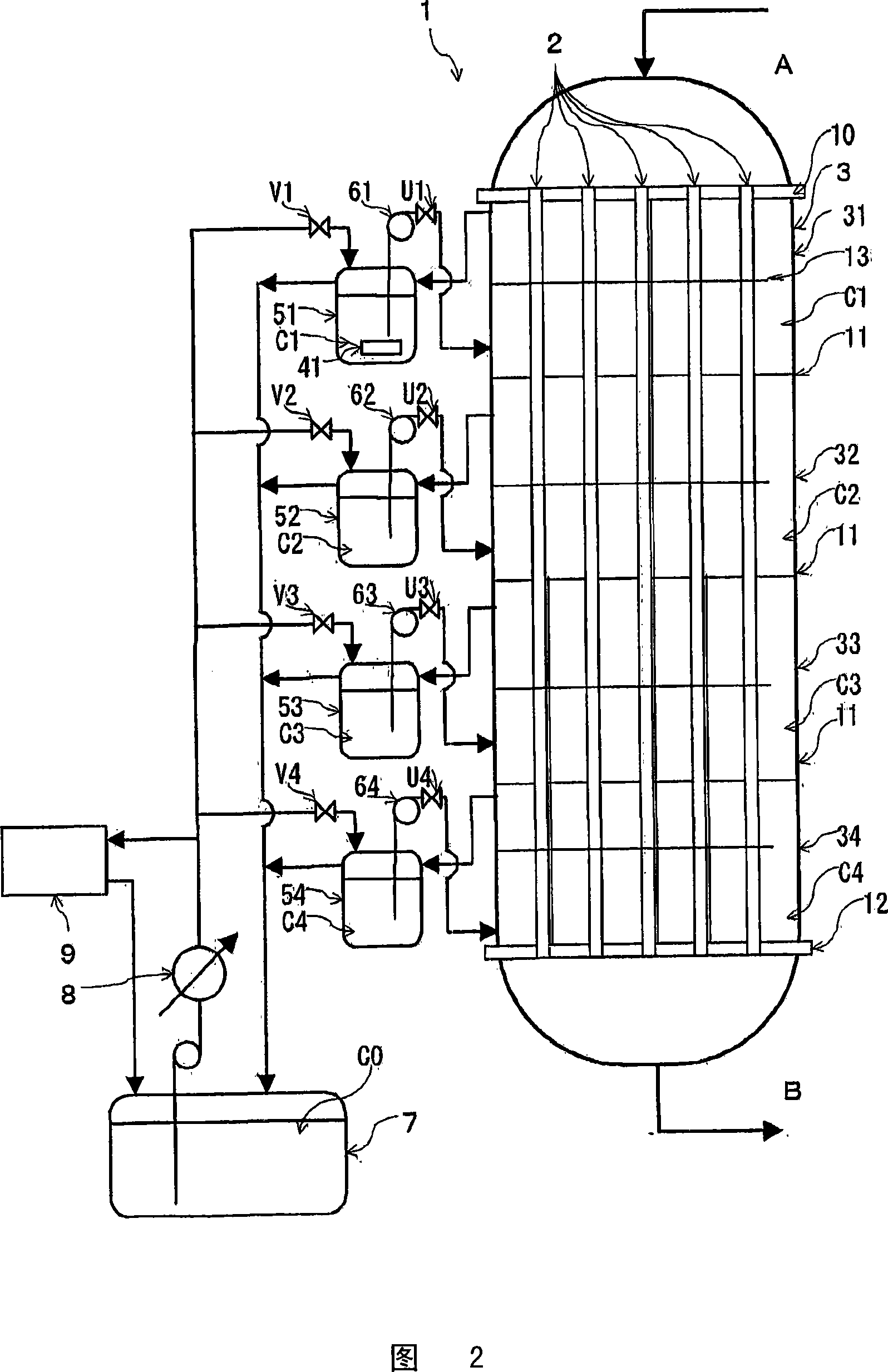

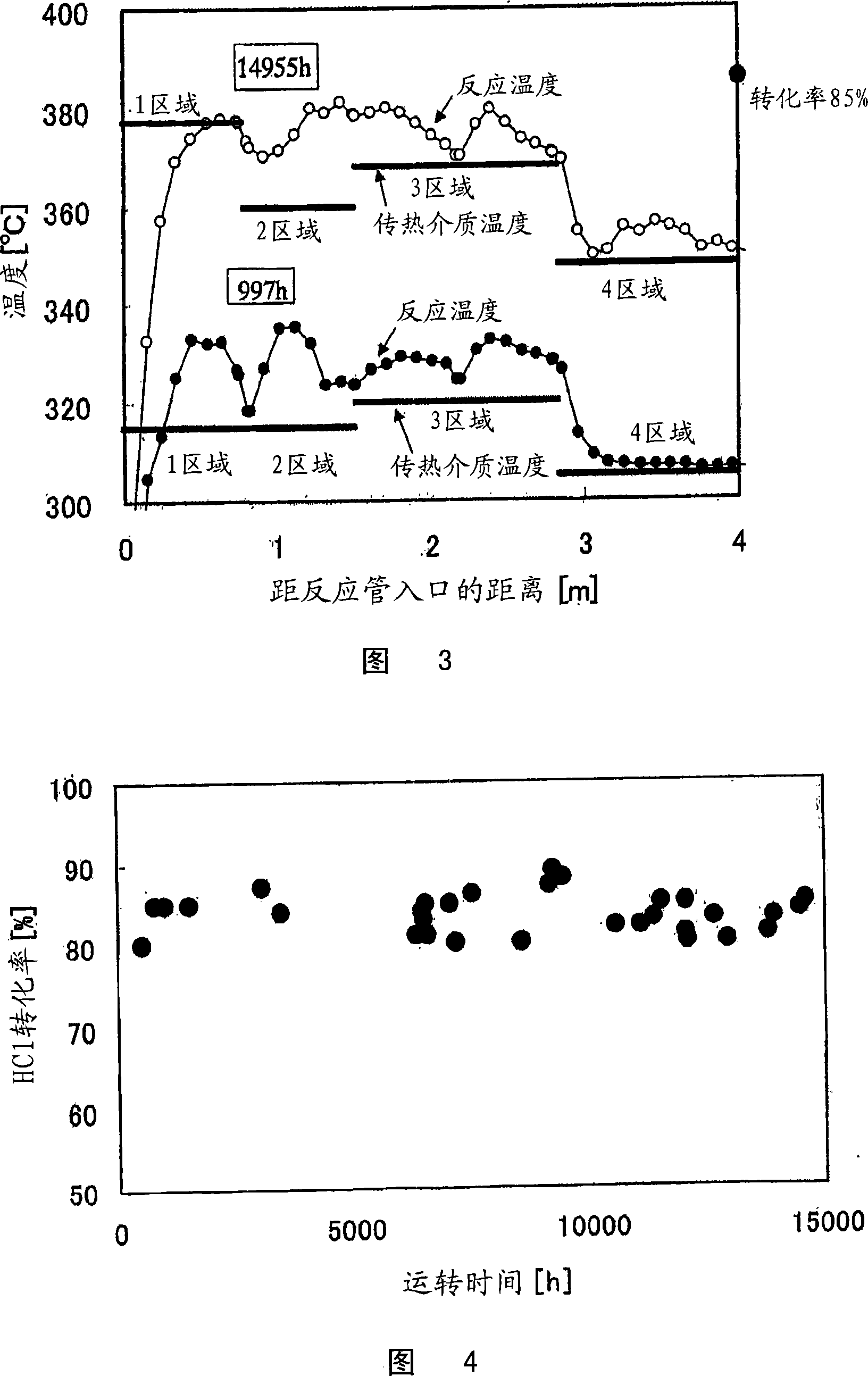

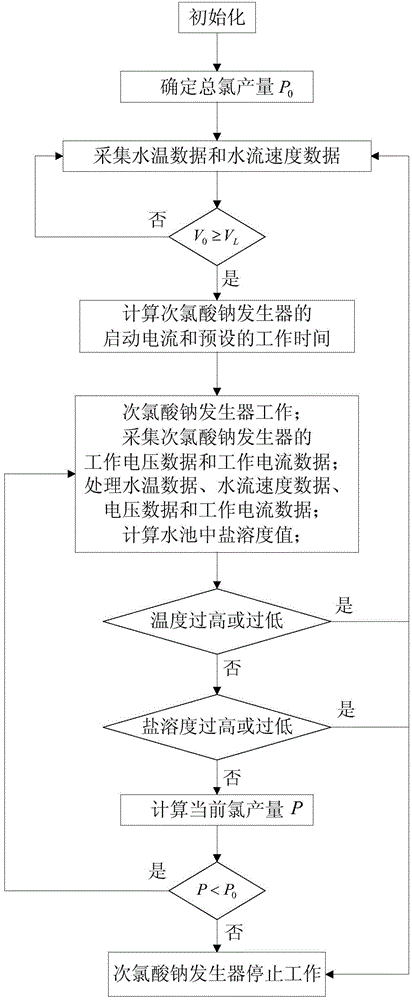

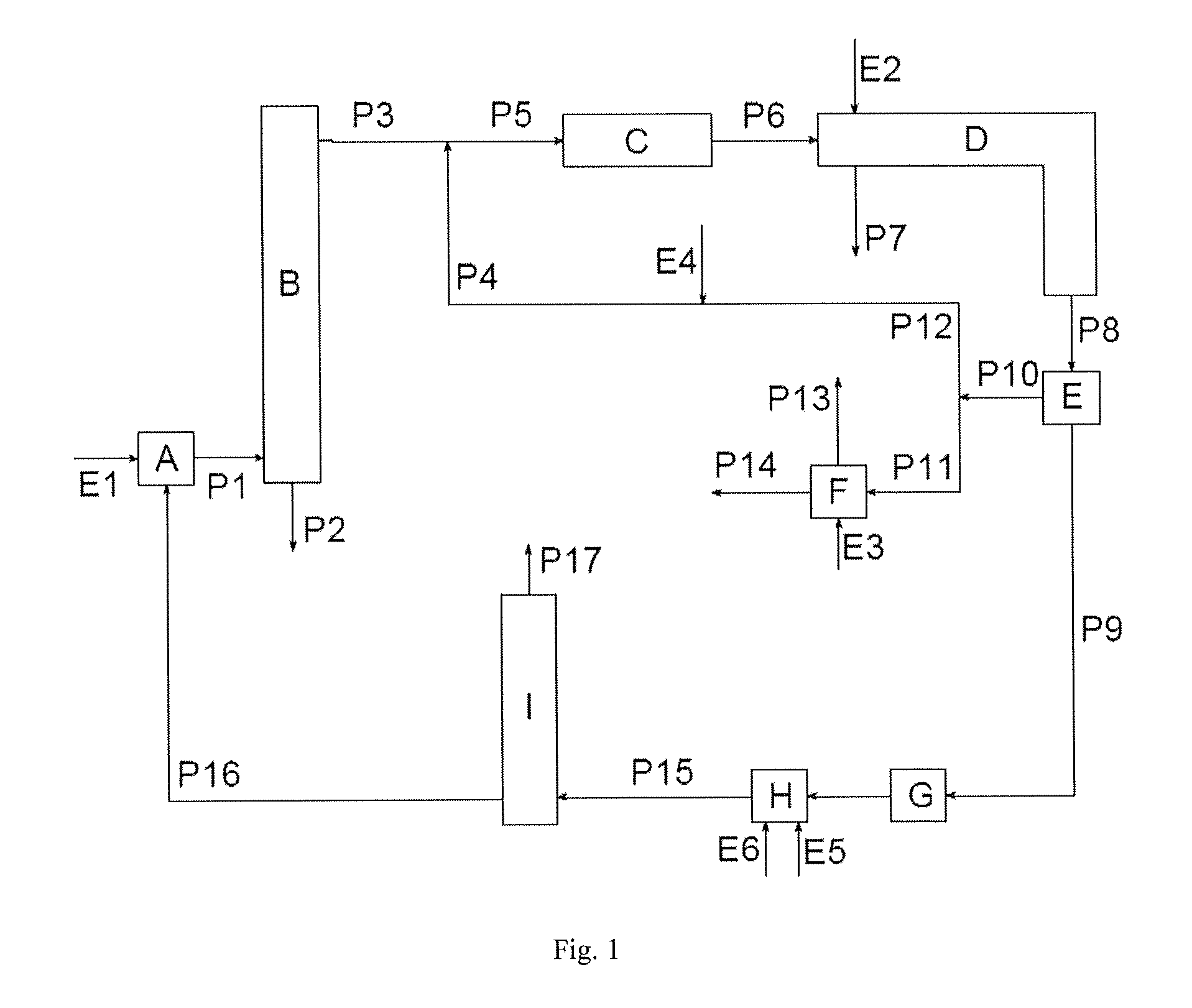

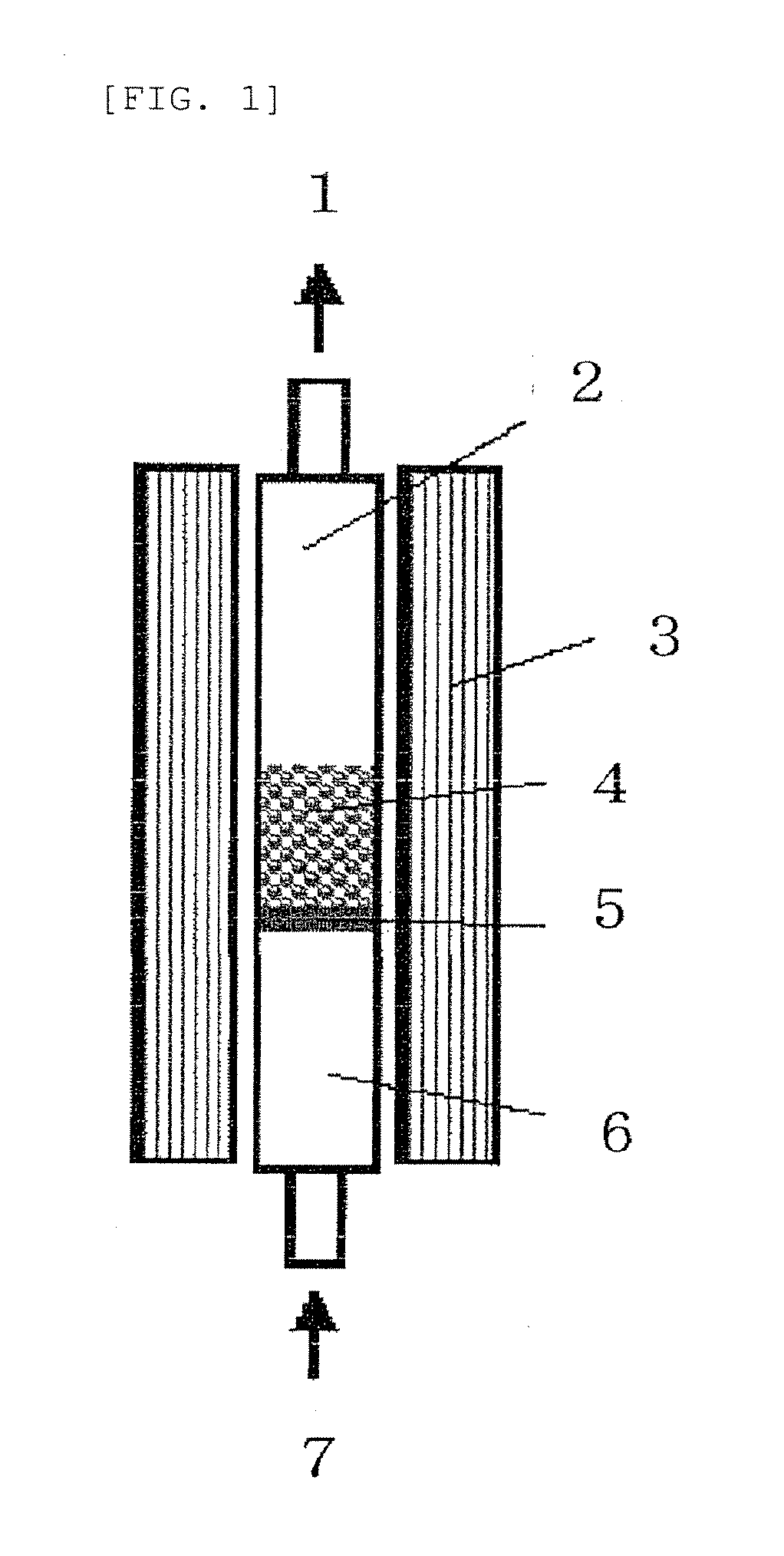

Reactor for chlorine production and process for producing chlorine

ActiveCN101223104AUse effectivelyStable maintenance of catalytic activityCatalyst activation/preparationStationary tubular conduit assembliesOxygenReaction tube

The reactor for chlorine production of the present invention is a multi-tubular heat exchange type reactor used when chlorine is produced by oxidizing hydrogen chloride, and is characterized in that the shell of the reactor is divided into a plurality of regions in the direction of the tube axis by partitions. In each zone, a heat transfer medium is circulated, and at least one temperature control device for the heat transfer medium is provided. The temperature control device is composed of a cooler and / or a heater. In the direction from the inlet to the outlet of the reactor reaction tube, the layer Filled with catalysts with different catalytic activities, the catalyst is a ruthenium oxide catalyst, filling less than 40% of the total amount of ruthenium in the area from the entrance of the reaction tube to less than 50%, and filling 60% of the total amount of ruthenium in the area of 50% to 100%. %above. In addition, the method for producing chlorine according to the present invention is characterized in that the chlorine production reactor is used, hydrogen chloride-containing gas and oxygen-containing gas are supplied to the chlorine production reactor, and at a pressure of 0.1 to 1 MPaG and a temperature of 200 to 500°C, Hydrogen chloride is oxidized with oxygen.

Owner:SUMITOMO CHEM CO LTD

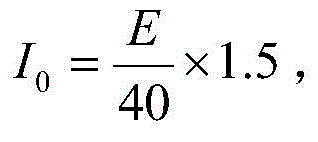

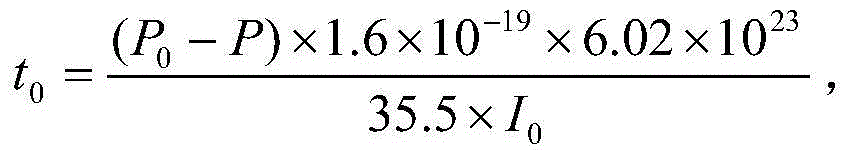

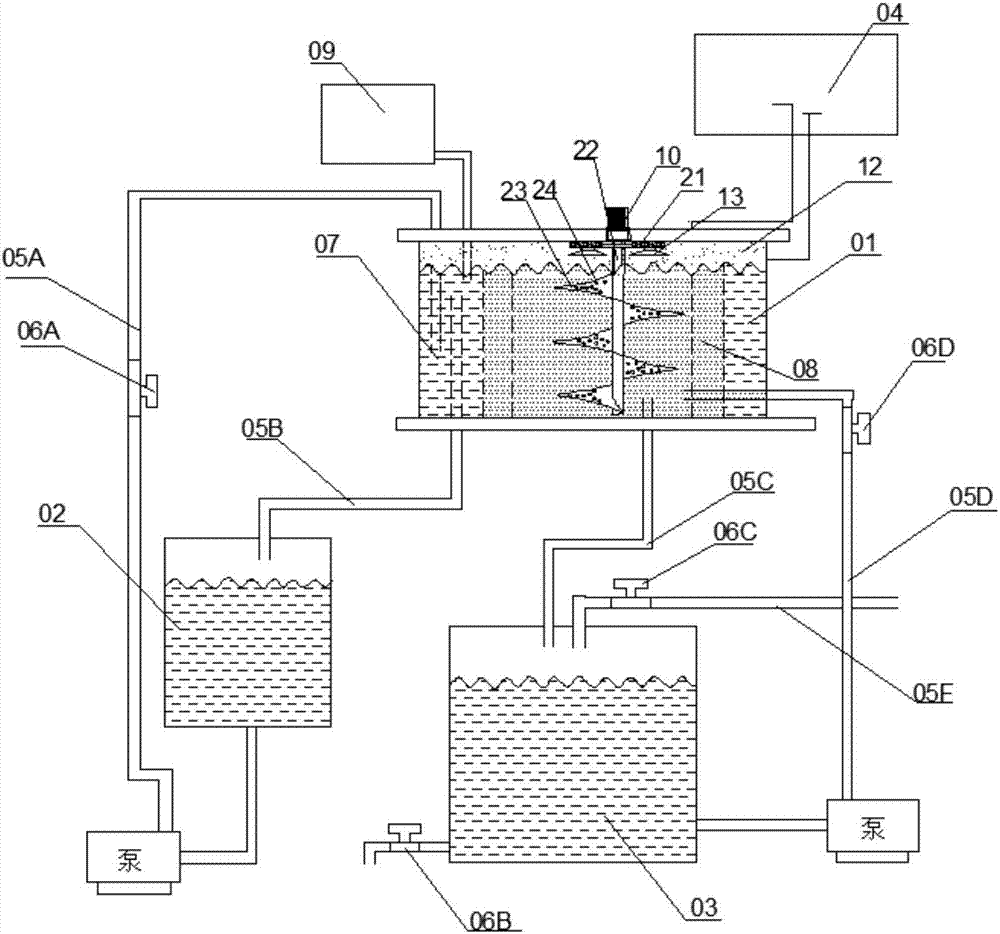

Swimming pool water chlorine production control method

ActiveCN104597929AReduce wasteEasy to controlControlling ratio of multiple fluid flowsChemical variable controlPower flowMarine engineering

The invention relates to a swimming pool water chlorine production control method. The swimming pool water chlorine production control method comprises the following steps of performing initialization to determine a swimming pool sterilization effect-achieved daily required total chlorine production amount; collecting water temperature and velocity data; according to the velocity data, determining whether to start or stop a sodium hypochlorite generator; collecting the working voltage and current data of the sodium hypochlorite generator, processing the water temperature and velocity data and the voltage and current data; computing a current chlorine production amount; comparing the current chlorine production amount with the swimming pool sterilization effect-achieved daily required total chlorine production amount, if the current chlorine production amount is smaller than the swimming pool sterilization effect-achieved daily required total chlorine production amount, performing feedback to continuously collect data, and if not, stopping the sodium hypochlorite generator. The swimming pool water chlorine production control method helps intelligently control the chlorine production in a swimming pool according to hydrochemical theories, thereby achieving accurate control to the chlorine production of the swimming pool when the swimming pool achieves sterilization effects.

Owner:NINGBO C F ELECTRONICS TECH CO LTD

Method for producing isocyanates

ActiveCN103130682AOrganic compound preparationIsocyanic acid derivatives purification/separationChlorine productionPhosgene

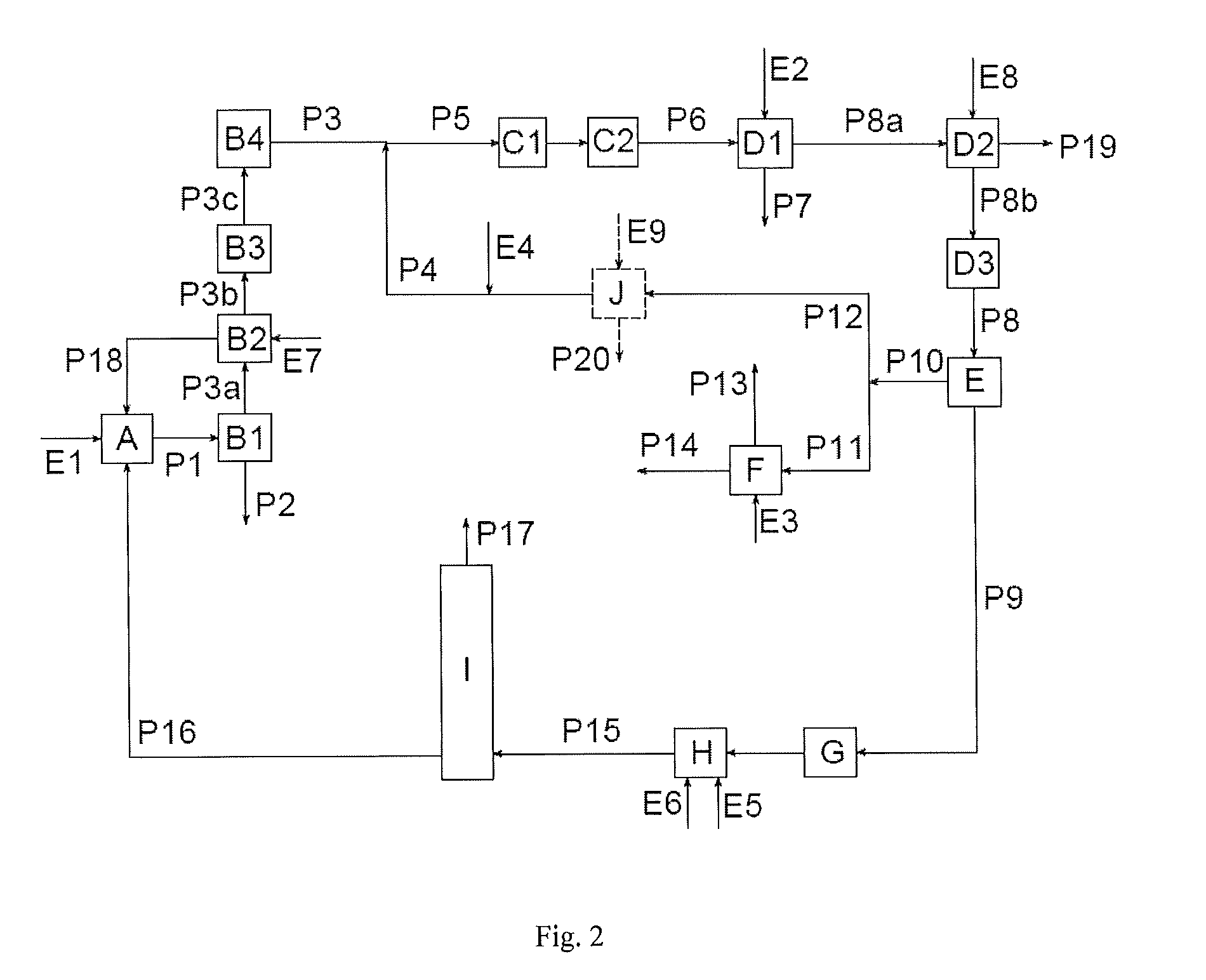

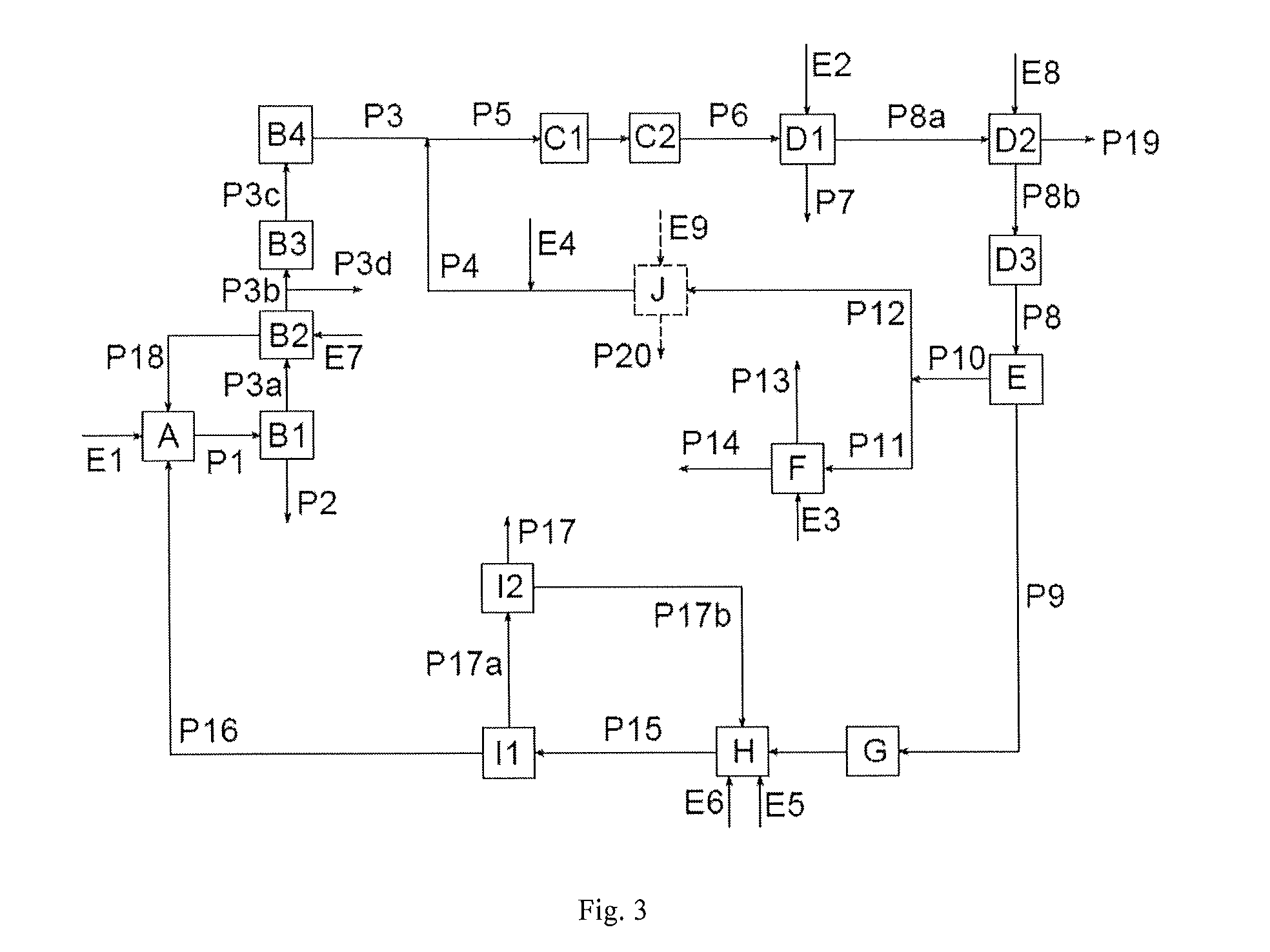

The invention relates to a process for the preparation of isocyanates in a system network comprising an isocyanate production plant, a chlorine production plant and a phosgene production plant, in which carbon dioxide formed as a by-product is partially to completely condensed out with the gaseous chlorine formed in the chlorine production plant and enters into the phosgene preparation process and, after the preparation of phosgene, the predominant part of the carbon dioxide formed is thereby sluiced out of the system network in gaseous form.

Owner:COVESTRO DEUTSCHLAND AG

Preparation method of catalyst for oxidization of hydrogen chloride for chlorine production

ActiveCN106861707AHigh reactivityLow priceMetal/metal-oxides/metal-hydroxide catalystsPreparation from chloridesPhysical chemistryChlorine production

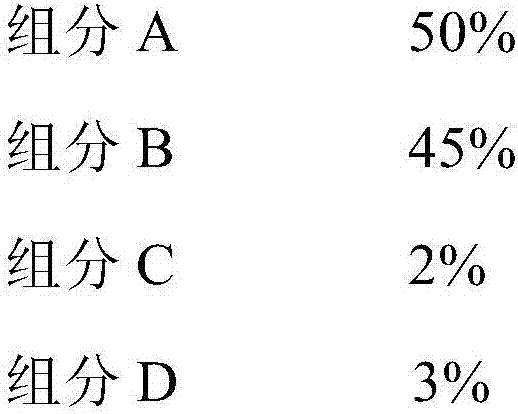

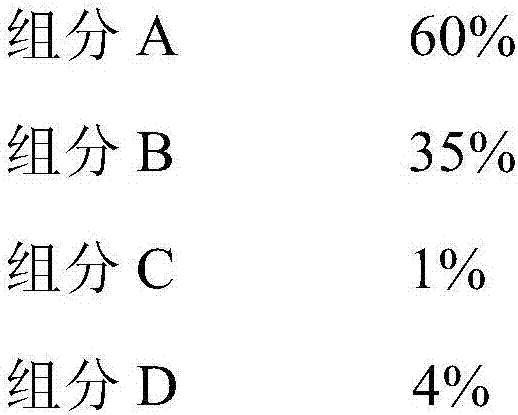

The invention discloses a preparation method of a catalyst for oxidization of hydrogen chloride for chlorine production. A catalyst precursor is prepared from the following components in percentage by mass: 50 to 60 percent of a component A, 35 to 50 percent of a component B, 1 to 2 percent of a component C and 3 to 5 percent of a component D, wherein the component A is chromic oxide; the component B is copper oxide; the component C is one or more of K<+>, Na<+> and Cs<+>; the component D is silicon oxide. The preparation method is characterized by comprising the following hydrogen chloride oxidization catalyst preparation steps: firstly, grinding the component A and the component B to obtain mixed metal oxide powder; secondly, immersing and modifying the metal oxide powder through the component C; finally, adding the component D, granulating and pressing the components, roasting, and carrying out fluorinated pore-forming activation through HF, thus obtaining the efficient hydrogen chloride oxidization catalyst.

Owner:XIAN MODERN CHEM RES INST

Graphene modified metal oxide anode material and preparation process

InactiveCN107974692AImprove microstructureImprove electrocatalytic activityLiquid/solution decomposition chemical coatingElectrodesChlorine productionTitanium

The invention discloses graphene modified metal oxide anode material and a preparation process. The graphene modified metal oxide anode material is characterized in that an active coating coats a titanium substrate, the active coating comprises RuO2, IrO2, SnO2, Sb2O3 and graphene, and coating liquid of the active coating comprises, by weight, 10-30% of Ru, 20-60% of Ir, 10-30% of Sn, 10-30% of Sband 0.1-10g / L of the graphene, wherein the total concentration of metal ions of the coating liquid is 0.10 to 0.35mol / L and the coating loading amount is larger than or equal to 10g / m<2>. Electrolysis efficiency of the anode coating in low-temperature seawater of 5 DEG C can be higher than 70%; and electrolysis efficiency of electrolysis chlorine production in the seawater with 10-20 PSUs of thelow-temperature seawater is more than or equal to 85%, and the accelerated electrolysis life is longer than or equal to 480 hours. In addition, the graphene is added into the coating, so that the bonding force between the coating and the substrate is improved, the passivation speed of the titanium substrate is relieved, stability of the coating is improved, and the service life of the coating is prolonged.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Method for activating catalyst for chlorine production

InactiveUS20100183499A1Produced cost-effectivelyReduced activityMolecular sieve catalystsCatalyst regeneration/reactivationHydrogenChlorine production

A catalyst having decreased activity is subjected to a contact treatment with a reducing gas containing carbon monoxide and / or hydrogen. Also, the catalyst can be effectively activated by being treated by contacting with an oxidizing gas after having been treated by contacting with the reducing gas. As the catalyst for production of chlorine, a ruthenium catalyst, particularly a catalyst containing ruthenium oxide is suitably activated.

Owner:SUMITOMO CHEM CO LTD

Process for the preparation of isocyanates

ActiveUS20130144081A1Improve mechanical stabilityOrganic compound preparationIsocyanic acid derivatives purification/separationChlorine productionPhosgene

The invention relates to a process for the preparation of isocyanates in a system network comprising an isocyanate production plant, a chlorine production plant and a phosgene production plant, in which carbon dioxide formed as a by-product is partially to completely condensed out with the gaseous chlorine formed in the chlorine production plant and enters into the phosgene preparation process and, after the preparation of phosgene, the predominant part of the carbon dioxide formed is thereby sluiced out of the system network in gaseous form.

Owner:COVESTRO DEUTSCHLAND AG

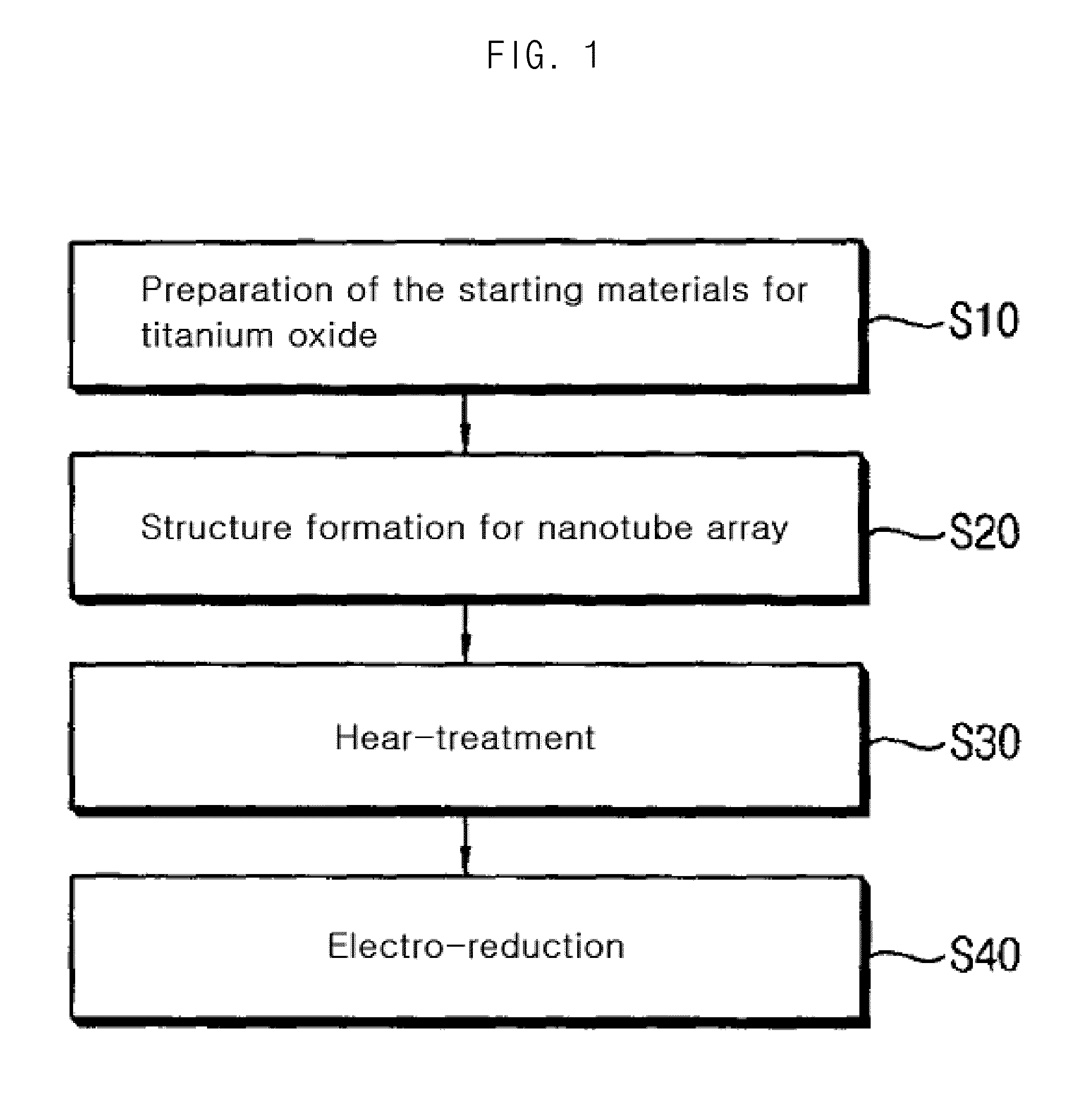

Manufacturing Method of Titanium Oxide Electrode, Active Oxygen Species Production System Including Same, Chlorine Production System, Dye-Sensitised Solar Cell and Electric Double-Layer Capacitor

ActiveUS20160168743A1Excellent active oxygen specie production efficiencyGood electrical propertiesCellsLight-sensitive devicesElectricityMetallurgy

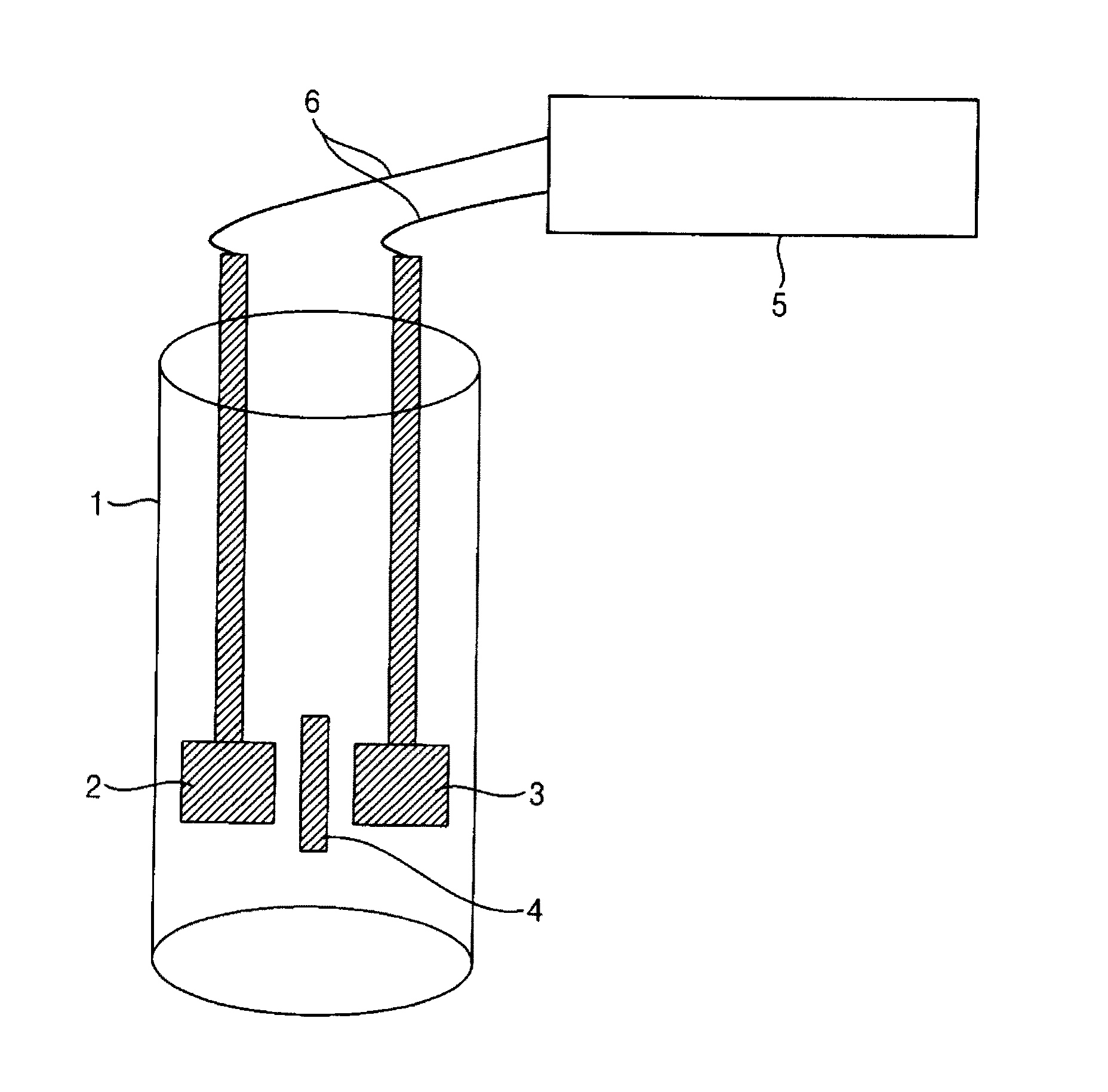

The disclosed manufacturing method of titanium oxide electrode comprises: preparing starting materials for titanium oxide, heat-treating the starting materials of titanium oxide, and electro-reducing the heat-treated starting materials of titanium oxide. According to this method, an anode having excellent active oxygen species production efficiency and excellent electrical properties can be manufactured using inexpensive titanium oxide.

Owner:SEOUL NAT UNIV R&DB FOUND

Zero-discharge system for quality-divided treatment of high-salinity wastewater of power plant

The invention discloses a zero-emission system for quality-divided treatment of high-salinity wastewater of a power plant, and belongs to the field of water treatment of thermal power plants. The system comprises a pretreatment system, a salt separation and purification system, a regeneration system and a production system. The salt-containing wastewater sequentially passes through the pretreatment system, the salt separation and purification system, the regeneration system and the production system; the regeneration system comprises bipolar membrane electrodialysis, an acidic water storage tank, an alkaline water storage tank, an electrolytic chlorine production device and a sodium hypochlorite storage tank. According to the present invention, the whole zero emission is provided, the external raw material addition is reduced, and the treatment cost is reduced.

Owner:JIANGSU HAIRONG THERMAL ANDENVIRONMENTAL ENG CO LTD

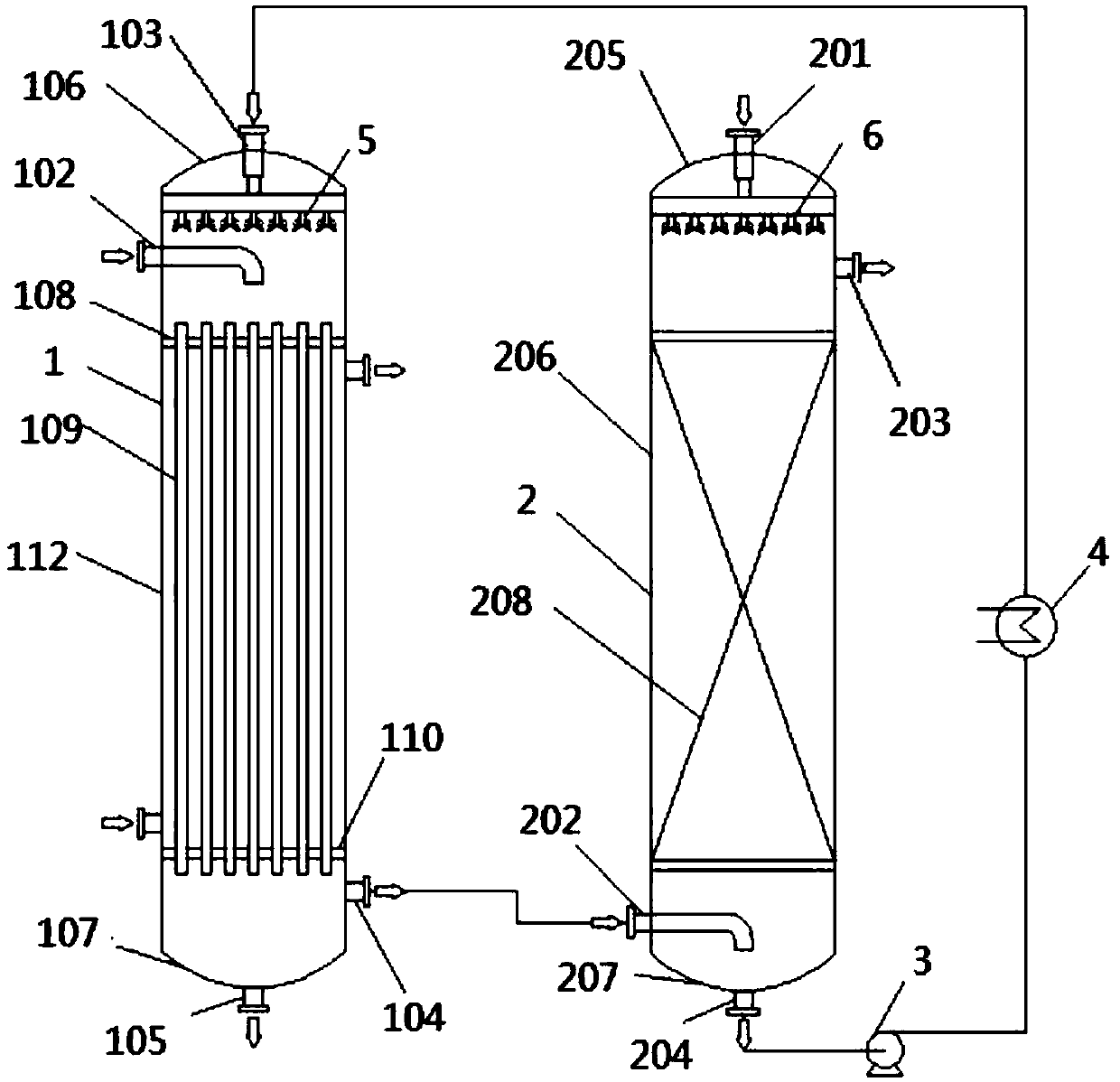

Device for absorbing hydrogen chloride in hydrogen chloride catalytic oxidation chlorine production process gas

InactiveCN107754566AWith anti-corrosion functionLong-term useGas treatmentChlorine/hydrogen-chloride purificationCatalytic oxidationHeat exchanger

The invention discloses a device for absorbing hydrogen chloride in a hydrogen chloride catalytic oxidation chlorine production process gas. The device comprises a falling film absorber, a packing tower, a hydrochloric acid pump and a graphite heat exchanger, wherein a process gas inlet, a diluted acid inlet, a primary absorbed process gas outlet and a condensate outlet of the falling film absorber are made of tantalum; an absorbed water inlet, a primary absorbed process gas inlet, a secondary absorbed process gas outlet and a diluted acid outlet of the packing tower are made of tantalum; theupper sealing head of the falling film absorber, the lower sealing head of the falling film absorber, an upper packing tower absorber sealing head, a packing tower absorber cylinder and a lower packing tower absorber sealing head are made of steel lined organic silicon steeped impermeable graphite; a fixing tube plate, an absorption tube and a floating tube plate of the falling film absorber are made of organic silicon steeped impermeable graphite; the falling film absorber cylinder is made of stainless steel; the packing is ceramic plate corrugated or high-silicon ceramic packing. The deviceis capable of effectively absorbing hydrogen chloride in process gases and can be used for a long time as a part in contact with a corrosive liquid has a corrosion resistant function.

Owner:SHANGHAI CHLOR ALKALI CHEM

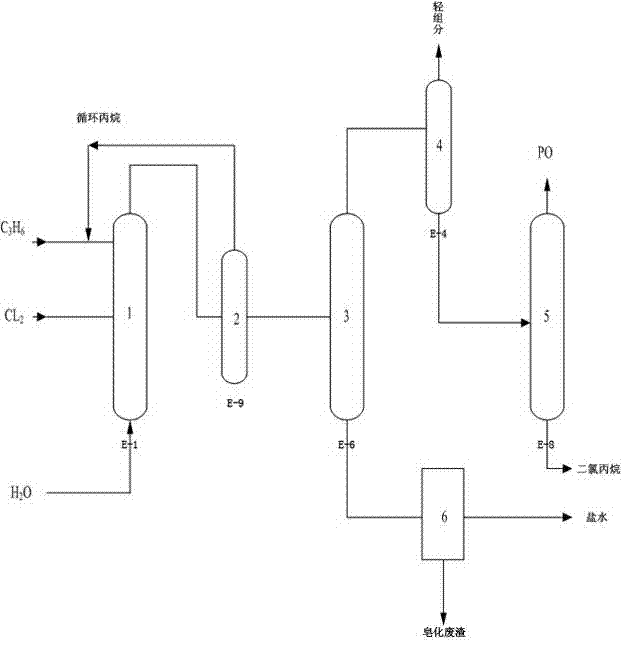

Method used for combined production of hydrazine hydrate and calcium chloride by saponification slag

ActiveCN103482590AReduce pollutionSave raw materialsCalcium/strontium/barium chloridesHydrazineSal ammoniacSlag

The invention discloses a method used for combined production of hydrazine hydrate and calcium chloride by waste saponification slag, and relates to a method used for preparing calcium chloride. The method comprises following steps: chlorine gas is delivered into waste saponification slag obtained in production processes of epoxypropane so as to obtain calcium hypochlorite solution; calcium hypochlorite solution is reacted directly with ammoniacal liquor in the presence of Mo-Fe catalyst so as to obtain hydrazine hydrate, wherein Mo-Fe catalyst can be filtered for recycling, the distilling mother liquor of hydrazine hydrate is saturated calcium chloride solution and is used for producing solid calcium chloride, and the main component of filter residue obtained in production processes of hydrazine hydrate is CaCO3; and the filter residue is reacted with byproduct hydrochloric acid to produce calcium chloride solution, and solid calcium chloride is obtained finally. According to the method combined production of hydrazine hydrate and calcium chloride is realized by waste saponification slag, so that waste is changed into valuables, more than 60% of saponification slag is reduced, no new pollution sources are generated, and environment pollution is reduced greatly.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Low chlorine, multi-staged method for producing cycloaliphatic disocyanates

InactiveUS8536370B2Reduce environmental pollutionSuppress formation of N-methylPreparation from carboxylic acid nitrogen analoguesOrganic compound preparationAlkaneAlcohol

Low chlorine, multi-staged method for producing cycloaliphatic diisocyanates. The invention relates to a multi-staged method for the continuous low-chlorine production of cycloaliphatic diisocyanates, comprising the synthesis of diaminodipheynl alkanes, the hydration thereof into the corresponding cycloaliphatic diamines and the subsequent conversion of cycloaliphatic diamines to the corresponding cycloalkylene biscarbamates and the thermal cleaving of the latter into the cycloaliphatic diisocyanates and alcohol.

Owner:EVONIK DEGUSSA GMBH

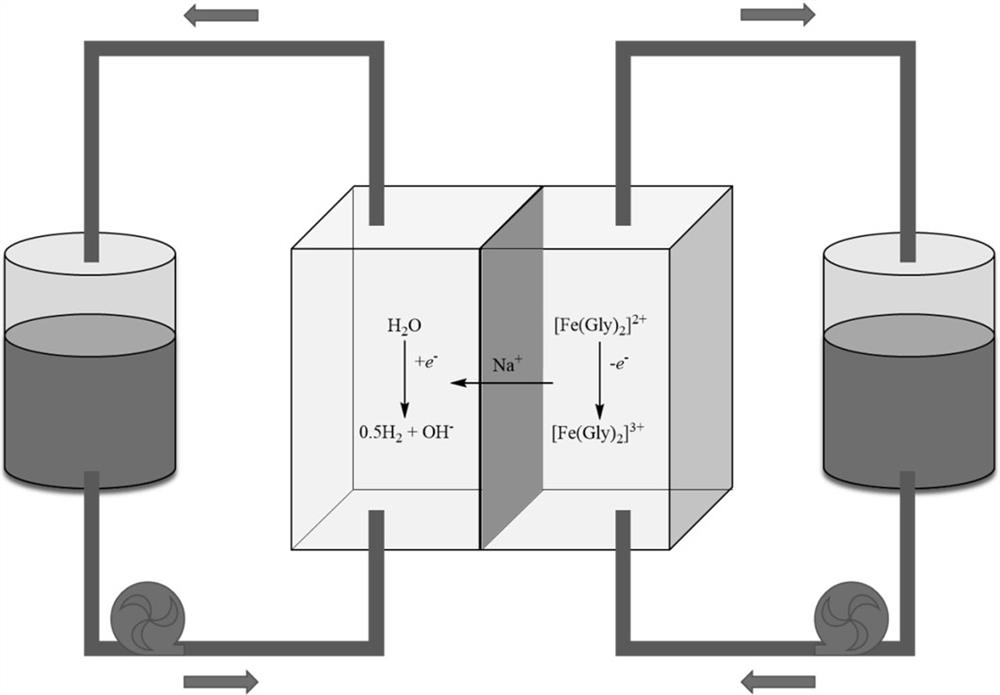

Co-production method of caustic soda and ferric orthophosphate

ActiveCN112853375AAvoid generatingSolve excess capacityElectrolysis componentsPhosphorus compoundsElectrolytic agentO-Phosphoric Acid

The invention belongs to the technical field of electrolysis, and particularly relates to a co-production method of caustic soda and ferric orthophosphate. The co-production method comprises the following steps: preparing NaOH and ferric ions by an electrolytic method, taking a cation exchange membrane and / or a microporous membrane as a separation membrane of a cathode and an anode, taking an aqueous solution containing sodium ions as a cathode electrolyte, and taking an aqueous solution containing ferrous ions and sodium ions as an anode electrolyte; preparing ferric orthophosphate by a chemical precipitation method; by using a ferric ion solution as a raw material, adding an aqueous solution containing phosphate ions as a precipitator to generate ferric orthophosphate. Compared with the traditional chlor-alkali process, the invention has the following advantages: the caustic soda process can avoid the generation of chlorine and overcome the excessive chlorine production capacity caused by caustic soda production; the oxidation potential (0.771 V vs SHE) of Fe < 2 + > is far lower than that (1.36 V vs SHE) of chloride ions, so that the energy consumption can be reduced; so that the produced FePO4 can be used for preparing a lithium ion or sodium ion battery electrode material.

Owner:FUDAN UNIV

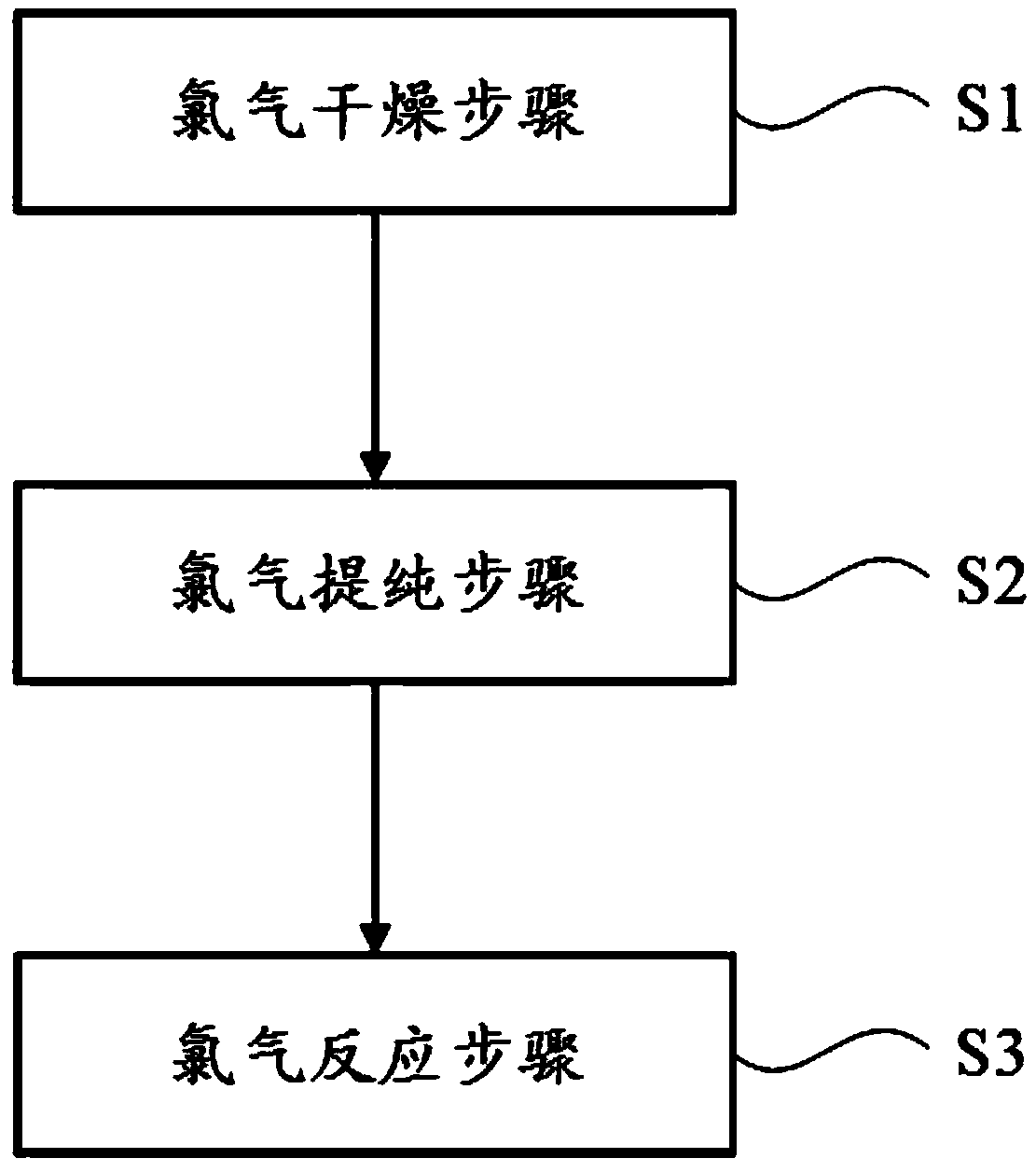

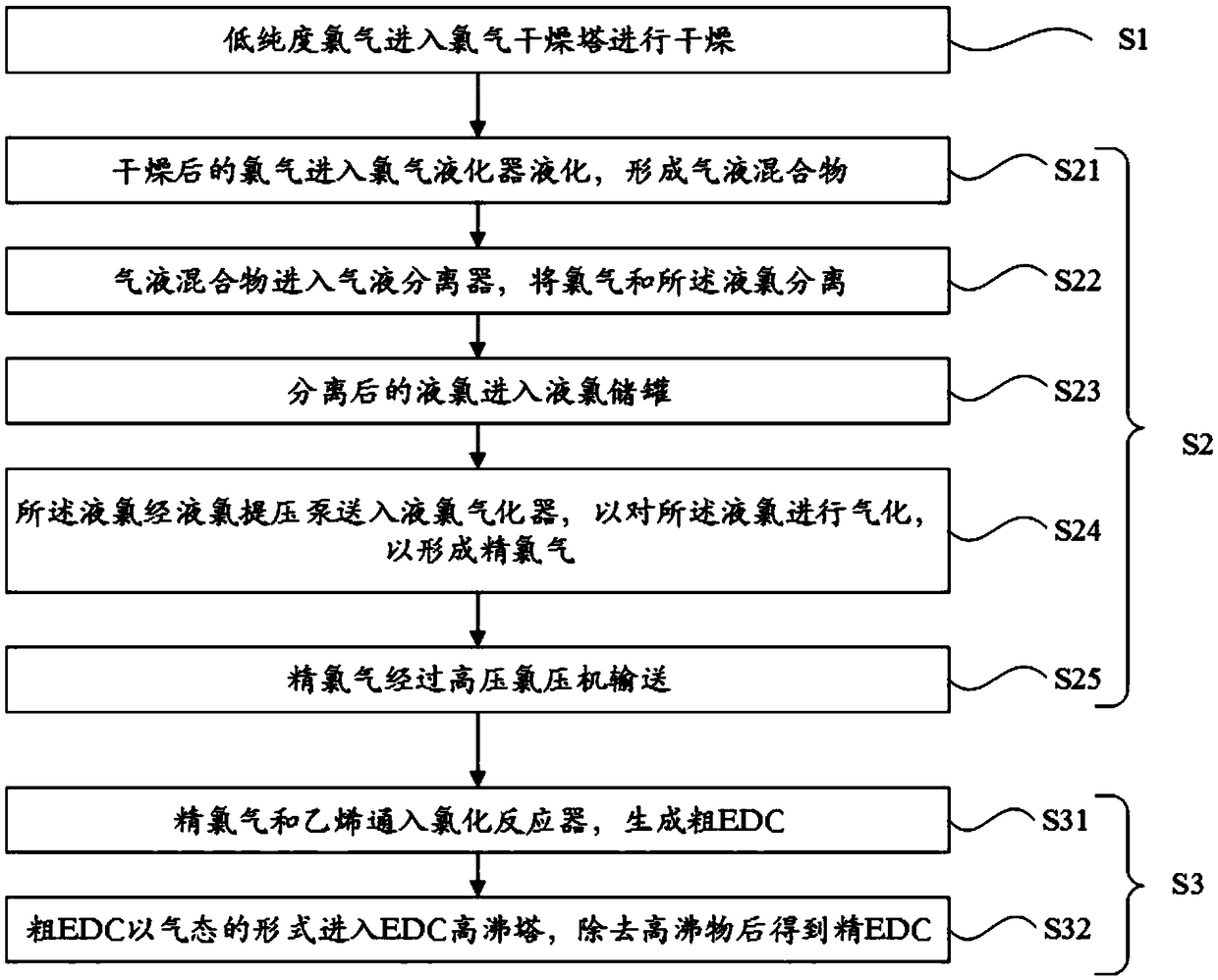

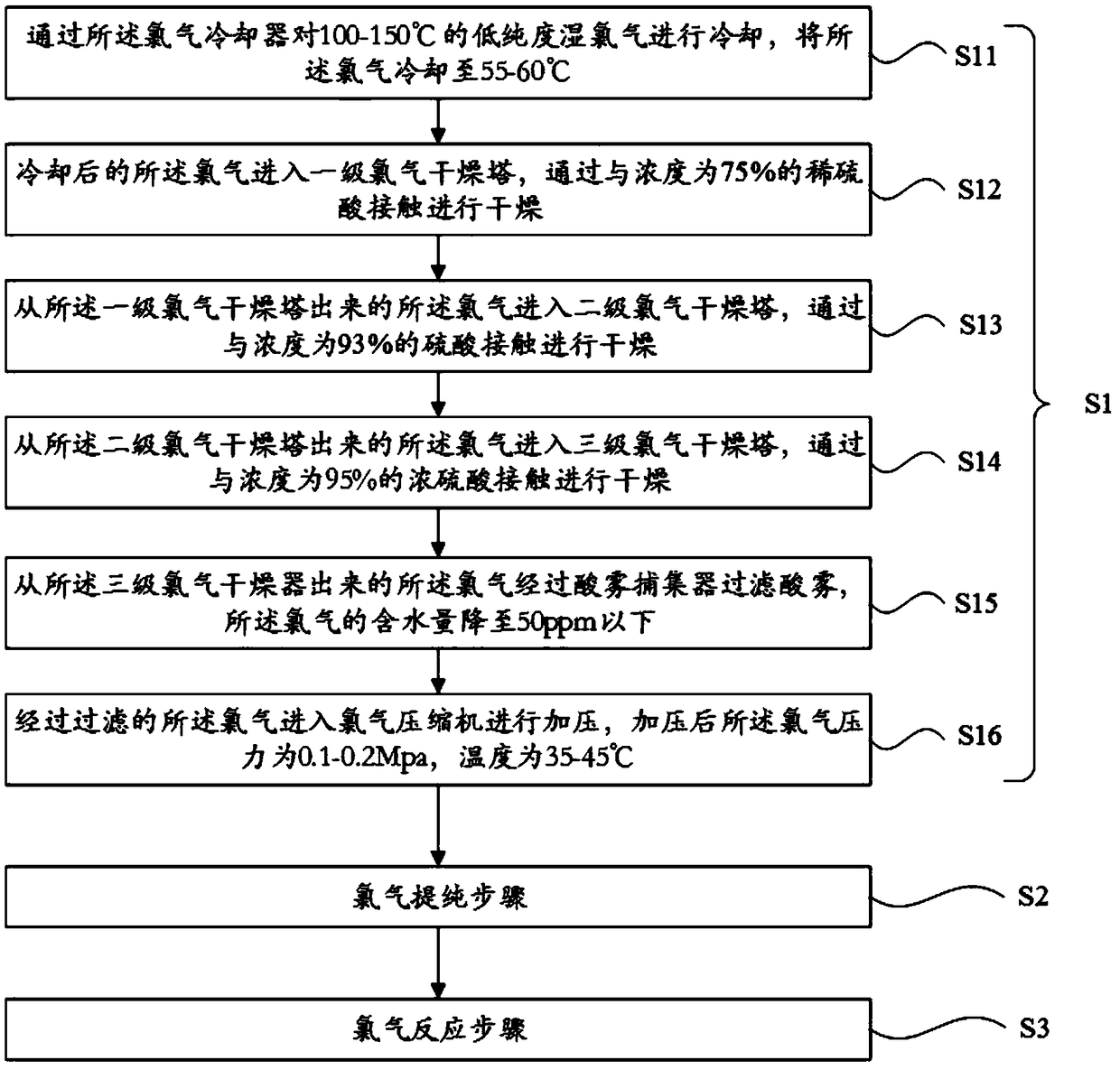

Method and system used for producing dichloroethane EDC from low purity chlorine gas

InactiveCN109180417AIncrease profitReduce usageHalogenated hydrocarbon preparationChlorine productionTower

The invention provides a method and a system used for producing dichloroethane EDC from low purity chlorine gas. The method comprises following steps: S1, chlorine gas drying, wherein a chlorine gas drying tower is adopted for drying of low purity chlorine gas; S2, chlorine gas purification, wherein the dried chlorine gas is subjected to liquefaction, gas liquid separation, liquid chlorine gasification, and pressurization for purification so as to obtain refined chlorine gas; and S3, chlorine gas reaction, wherein the refined chlorine gas and ethene are introduced into a chlorination reactor for reaction so as to obtain crude EDC, the crude EDC is delivered through an EDC high boiling tower to remove high boiling products so as to obtain refined EDC. According to the method, low purity chlorine gas is converted into dichloroethane EDC high in added value, chlorine gas utilization rate is increased, and using of sodium hydroxide is reduced. According to the method, low purity chlorine gas is subjected to drying and purifying so as to reduce corrosion of chlorine gas on equipment and pipelines in EDC production process, so that the quality of produced EDC is increased, production process safety and reliability are increased, and the application prospect is promising.

Owner:QINGHAI SALT LAKE IND

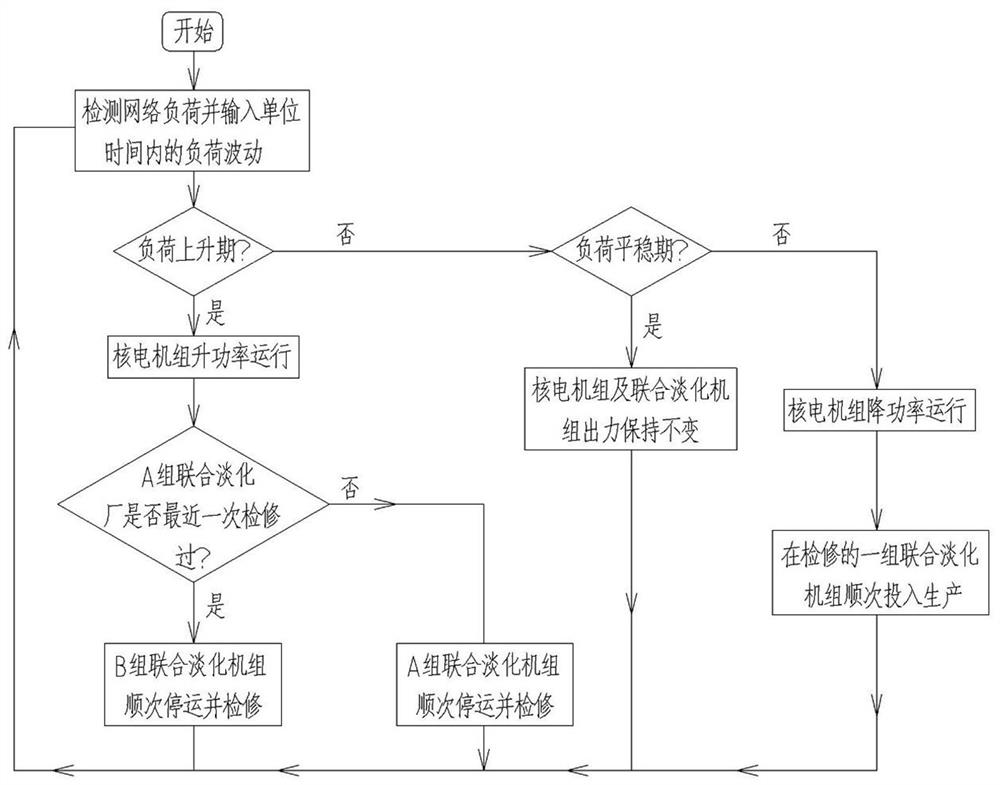

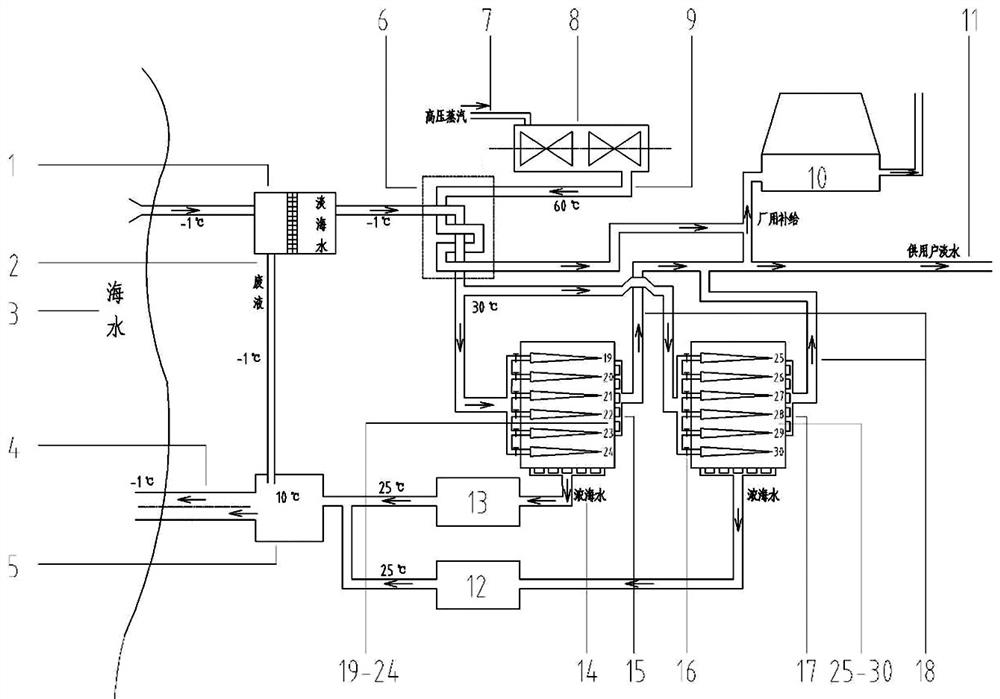

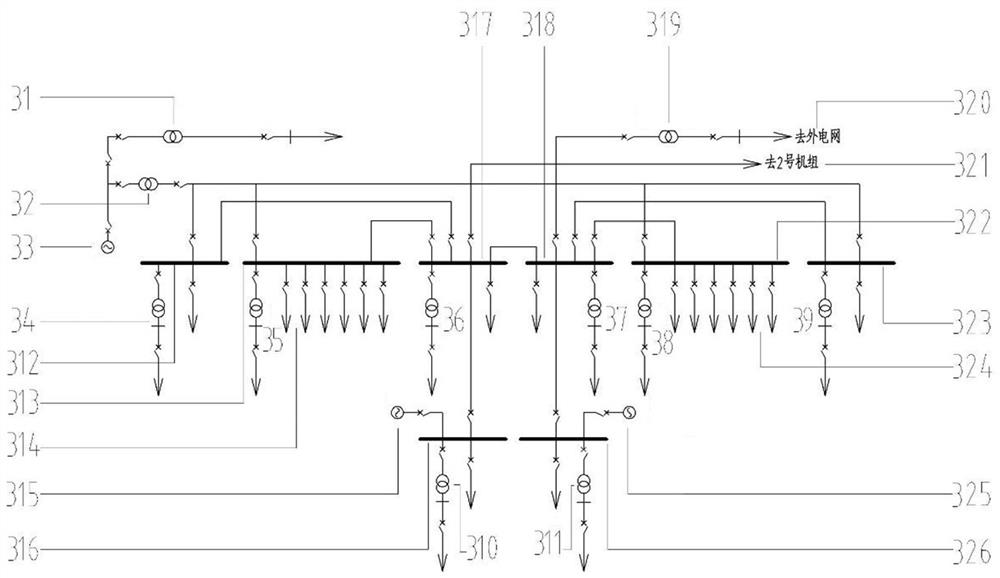

Nuclear power peak regulation system and method based on seawater desalination technology

ActiveCN109390980BLarge capacityExtended maintenance timeData processing applicationsSeawater treatmentNuclear powerProcess engineering

The present invention proposes a nuclear power peak regulation system and method based on seawater desalination technology. Multiple chlorine plants in Group B and Group B, and each desalination plant in each group works in parallel; the desalination plants in Group A are connected to the chlorine plants in Group A to form the first group of joint desalination plants; the desalination plants in Group B The plant is connected to the chlorine plant in group B to form the second group of combined desalination plants; the desalination plant and the chlorine plant are powered by nuclear power units, and each desalination plant is powered independently. The peak shaving method makes the nuclear power units run at full capacity during the peak load period, one of the two combined desalination plants is out of operation, and the two sets of combined desalination plants are put into operation at the same time during the off-peak period. Using hydropower cogeneration to meet the requirements of nuclear power units to participate in peak regulation, extend the operating time of nuclear power with base load, increase the minimum operating power of nuclear power units, and then improve the safety and economy of nuclear power operation.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

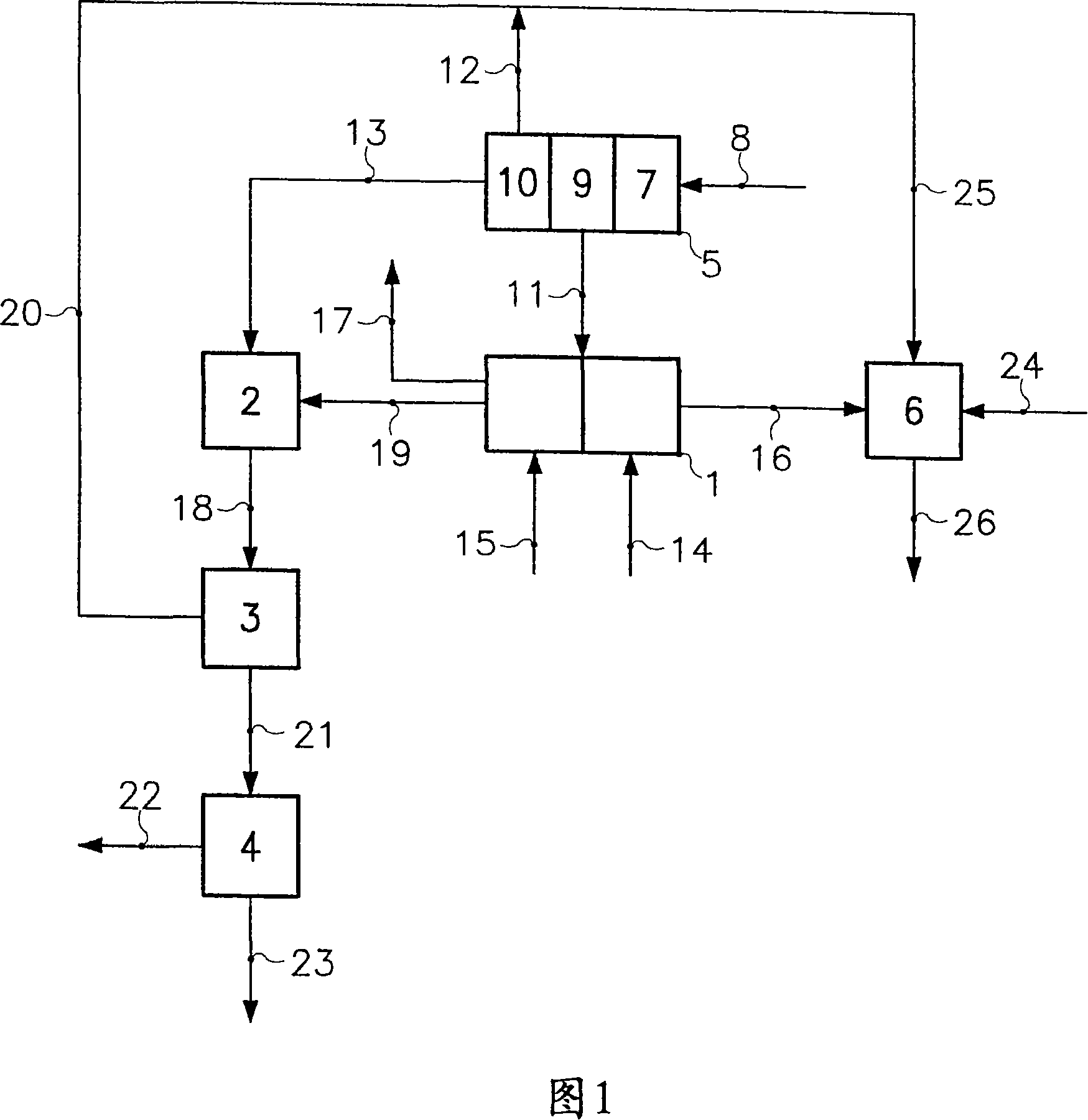

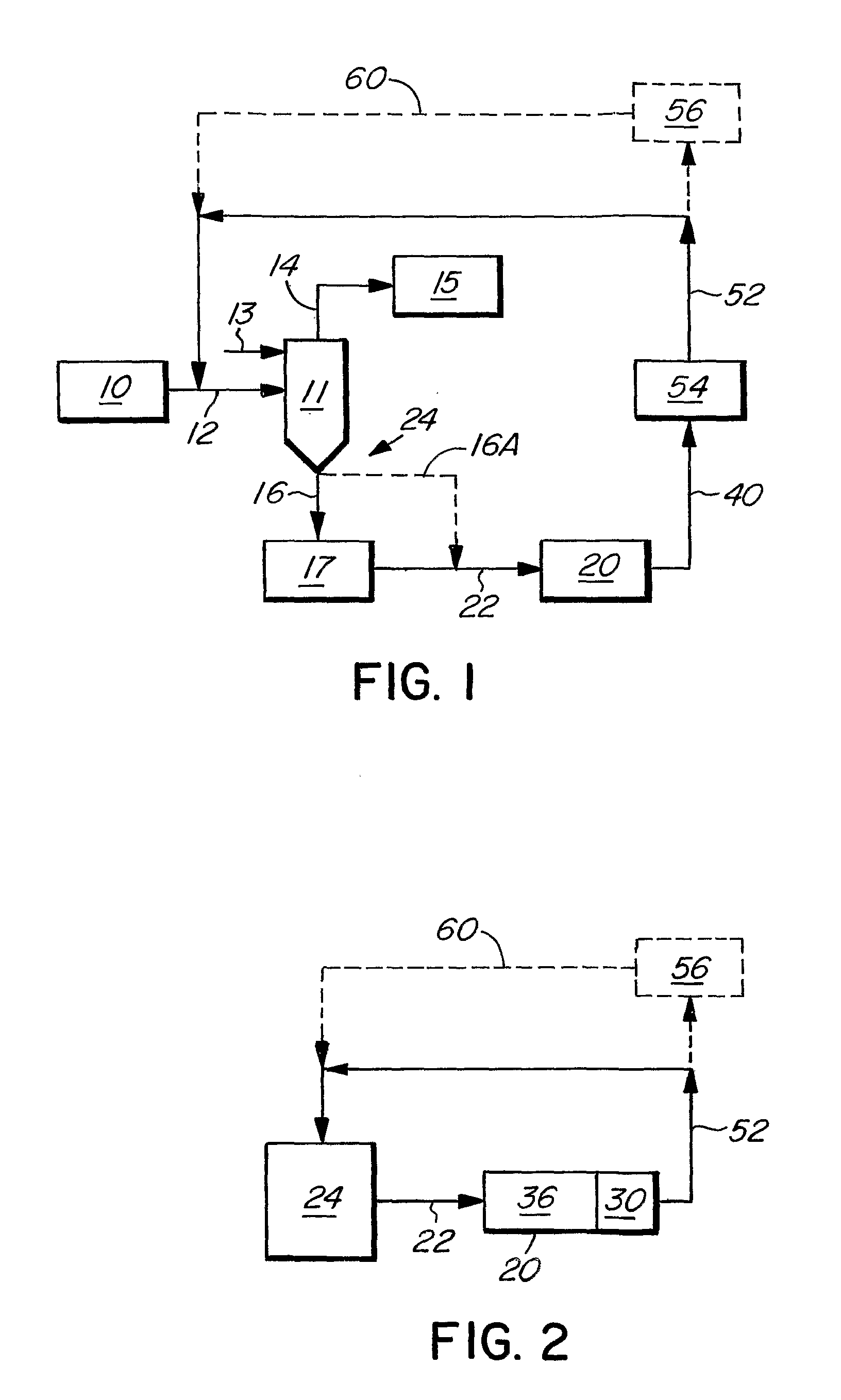

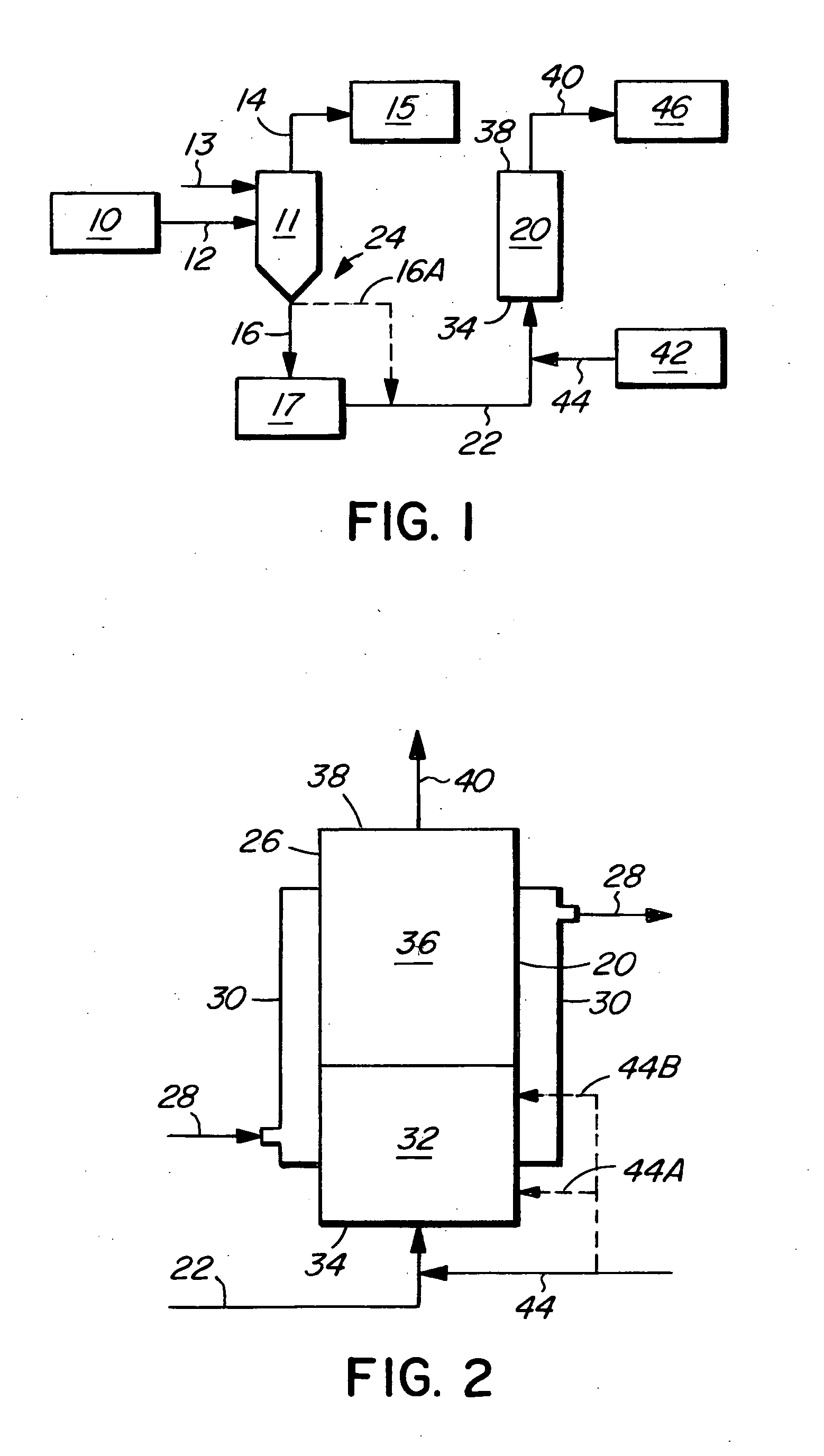

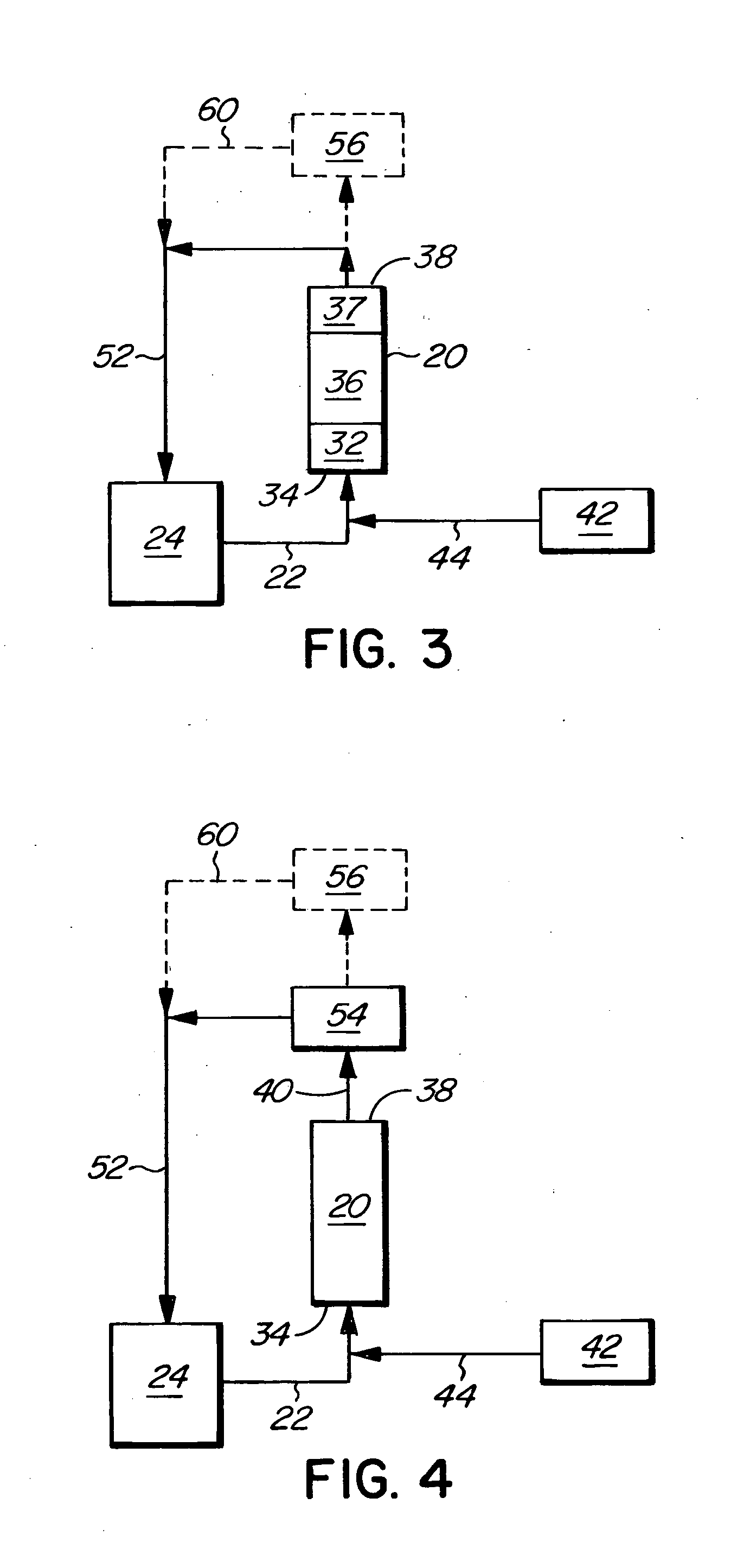

Process for jointly obtaining a chlorine derivative and crystals of sodium carbonate

InactiveCN101137771AEmission reductionLow costElectrolysis componentsFuel cell auxillariesCogenerationPermselective membrane

An aqueous solution of sodium chloride is electrolyzed in a cell (1) with an ion permselective membrane to produce, on the one hand, chlorine (16) which is converted in a chlorine production unit (6) and, on the other, an aqueous sodium hydroxide solution (19), which is carbonated using a flue gas (13) from an electricity and steam cogeneration unit (5), and the resulting carbonated solution (18) is evaporated to produce sodium carbonate crystals (21).

Owner:SOLVAY SA

Chlorine production catalyst and chlorine production process using the catalyst

ActiveUS20120009117A1High reactivityLong catalyst lifeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedLanthanide

The invention provides a chlorine production catalyst that shows excellent reaction activity in the oxidation reaction of hydrogen chloride with oxygen into chlorine, is inexpensive and can be supplied stably, and is suited for use in a fluidized-bed reactor. The invention also provides a chlorine production process using the catalyst. The chlorine production catalyst of the invention includes spherical particles containing copper element (A), an alkali metal element (B) and a lanthanoid element (C) and having an average sphericity of not less than 0.80. The lanthanoid element (C) has a bond dissociation energy with oxygen at 298 K of 100 to 185 kcal / mol. The content of the copper element (A) in the catalyst is 0.3 wt % to 4.5 wt %.

Owner:MITSUI CHEM INC

Method of processing liquid chlorine containing nitrogen trichloride

A method of processing a stream of liquid chlorine containing nitrogen trichloride from a chloralkali plant. The liquid stream is received into a vaporizer in which it is evaporated 1O1 chlorine gas and nitrogen trichloride gas. The gas stream is processed by destroying the nitrogen trichloride gas, for example in a superheater or a catalytic bed. The processed gas stream is recycled to the chlorine production train of the chloralkali plant. The process avoids the use of organic solvents to decompose the nitrogen trichloride and the creation of a waste stream requiring further handling.

Owner:NORAM INT

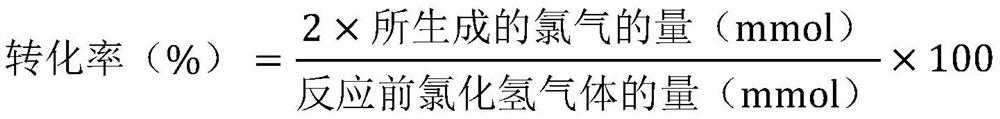

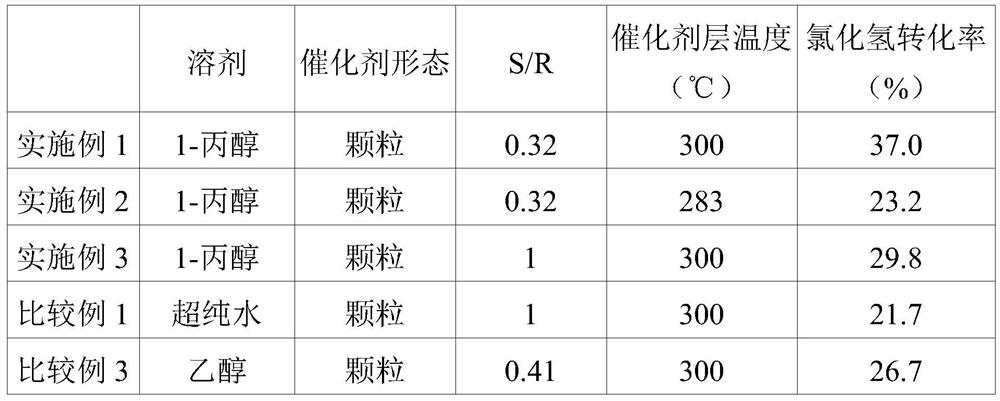

Method for manufacturing ruthenium oxide-supported catalyst for preparing chlorine and catalyst manufactured thereby

PendingCN113242767AGood for scaling upScale upCatalyst activation/preparationCalcinationPtru catalystOrganic solvent

The present invention relates to a method for manufacturing a ruthenium oxide-supported catalyst for preparing chlorine and, more specifically, to a method for manufacturing a catalyst and a catalyst manufactured thereby, wherein the catalyst contains a ruthenium ingredient of which the support level on the outer surface of the support is significantly improved, and the use of the catalyst in chlorine production can provide a high conversion rate of chlorine even at a low reaction temperature. Provided according to an embodiment of the present invention is a method for manufacturing a ruthenium oxide-supported catalyst for preparing chlorine, the method comprising the steps of: (a) dissolving a ruthenium compound in an organic solvent to prepare a solution and supporting same on at least one support selected from among titania and alumina; (b) drying; and (c) sintering. According to an embodiment of the present invention, specifically, a simplified process is provided, wherein a catalyst containing ruthenium oxide only at the outer surface layer of a titania support can be prepared without an alkaline pretreatment, thereby exhibiting an advantageous effect in terms of scale-up.

Owner:HANWHA SOLUTIONS CORP

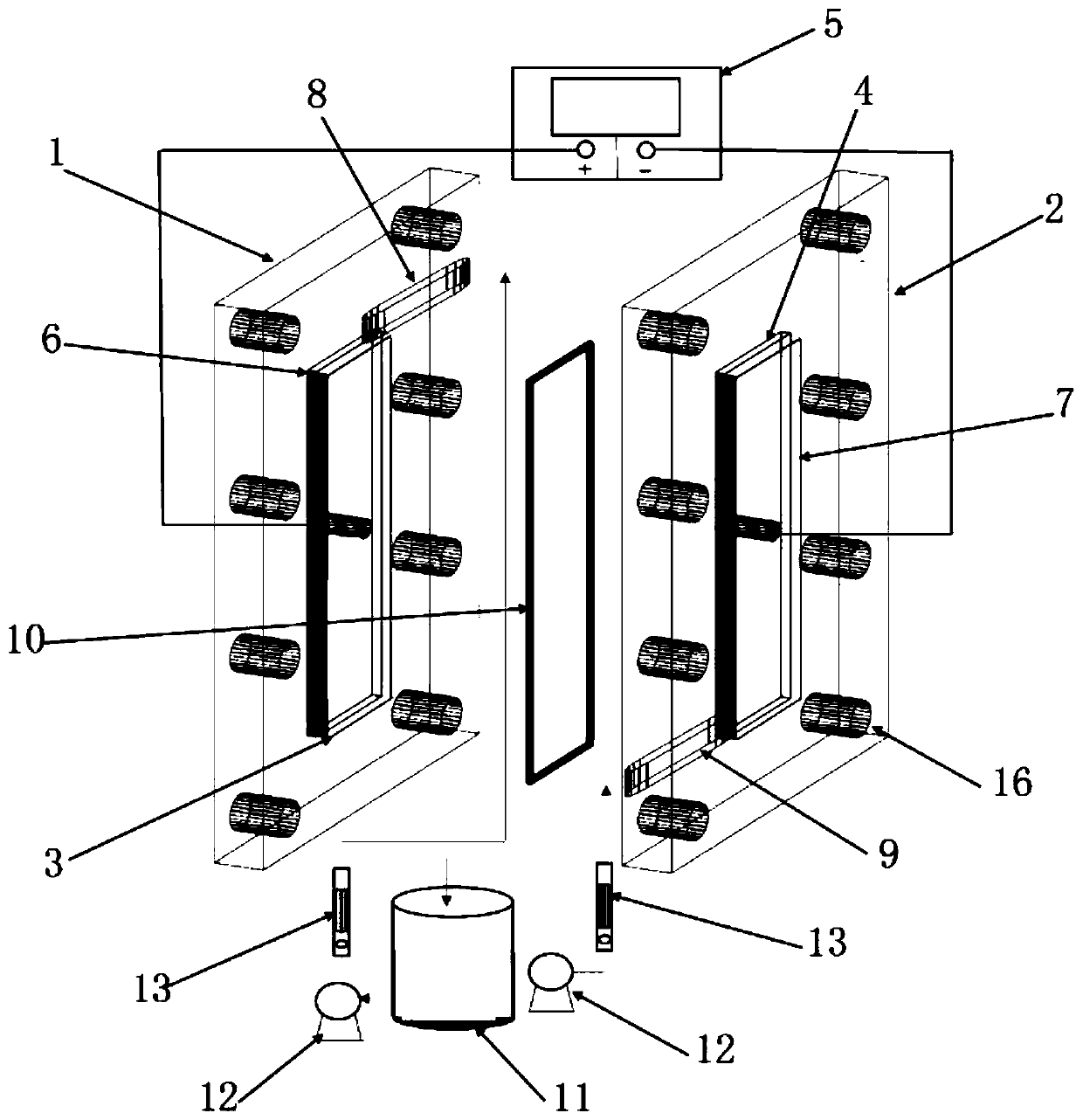

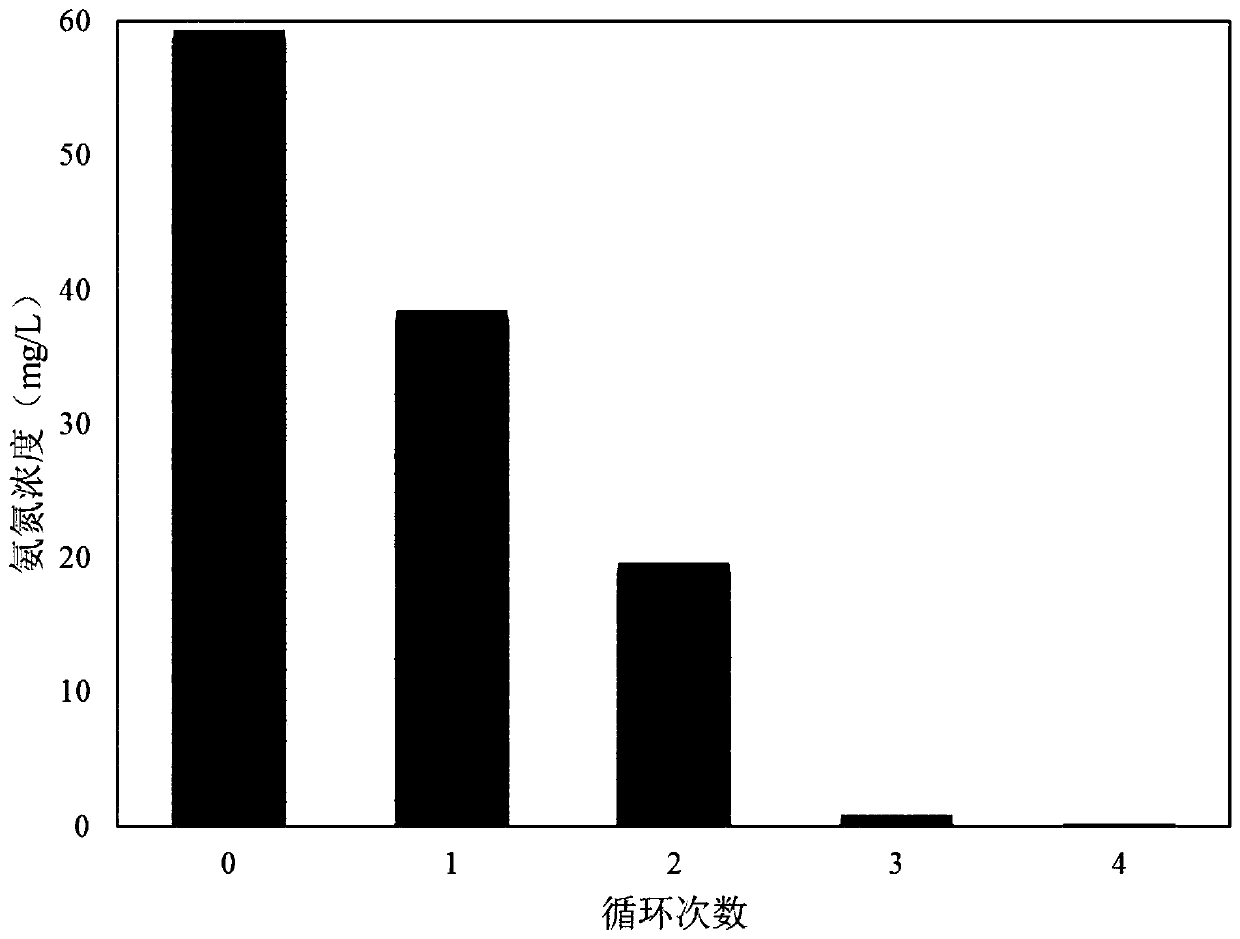

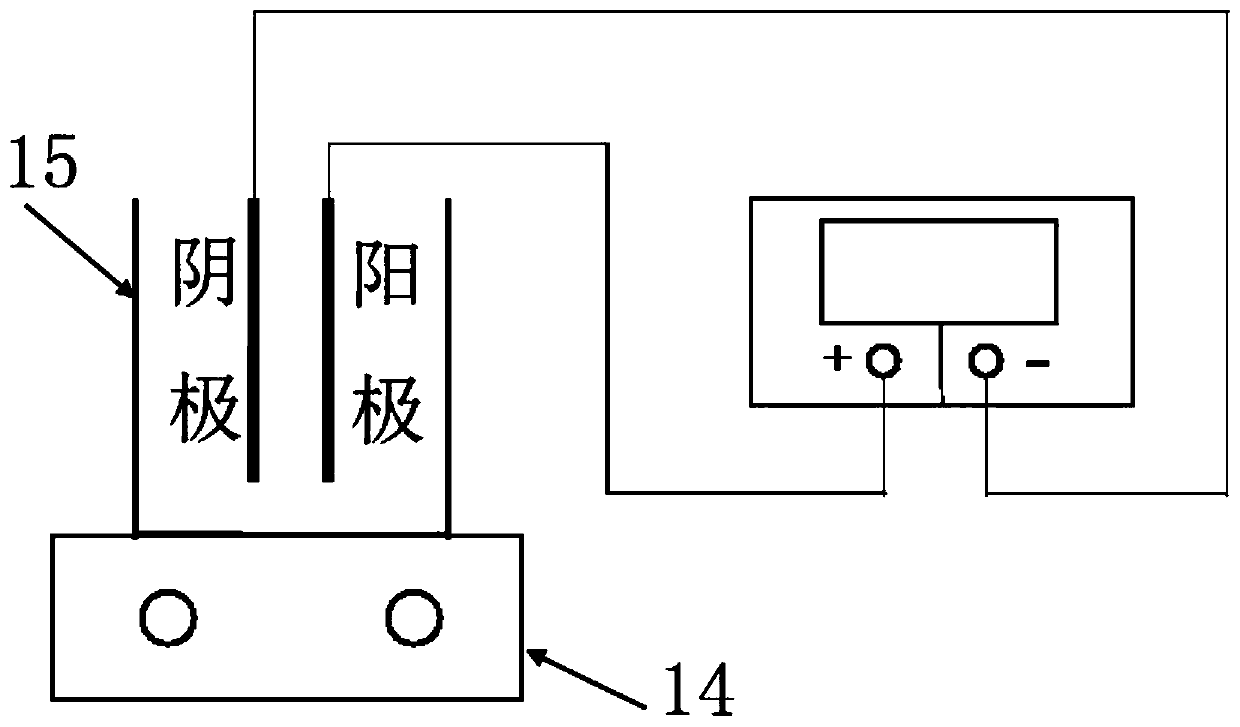

Electrochemical ammonium micro-nano reactor, preparation method of anode material and ammonium removal application thereof

ActiveCN110668532ALarge adsorption capacityHigh selectivityWater treatment parameter controlOther chemical processesHypochloriteSorbent

The invention provides an electrochemical ammonium micro-nano reactor, a preparation method of an anode material thereof and ammonium removal application, and belongs to the technical field of sewageammonium removal. The electrochemical ammonium micro-nano reactor comprises an anode material and a cathode material, wherein the anode material and the cathode material are respectively connected with an anode and a cathode of a direct current power supply; a first support plate is provided with a first groove, and the anode material is arranged in the first groove; a second support plate is provided with a second groove, and the cathode material is arranged in the second groove. The anode material comprises an ammonium ion sieve material which exchanges ammonium ions from a water body to enrich the ammonium ions in the water body to an electrochemical anode; and a chloride ion adsorbent absorbing chloride ions in water. After being electrified, the chloride ions are oxidized into chlorine, the chlorine meets water to form active hypochlorite, and the chlorate oxidizes the ammonium ions adsorbed by the ammonium ion sieve into nitrogen. According to the invention, the ammonium ions insewage are adsorbed in large quantities, the chloride ions in water bodies are adsorbed, electrochemical chlorine production efficiency is increased, and cost is saved; the product is clean, the reaction is efficient, reusing can be realized, and the reaction process can be continuously carried out.

Owner:BEIJING ORIGINWATER TECH CO LTD

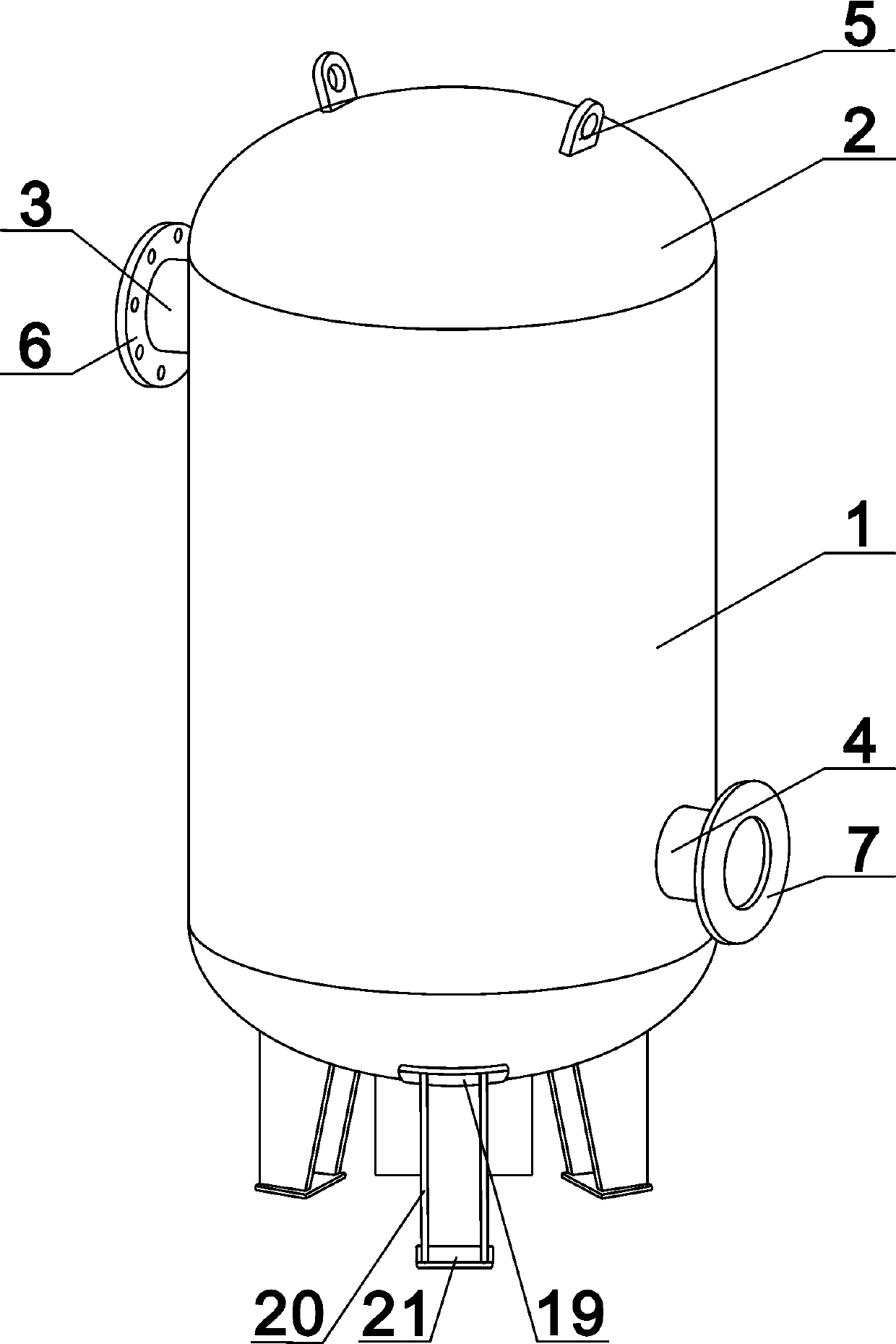

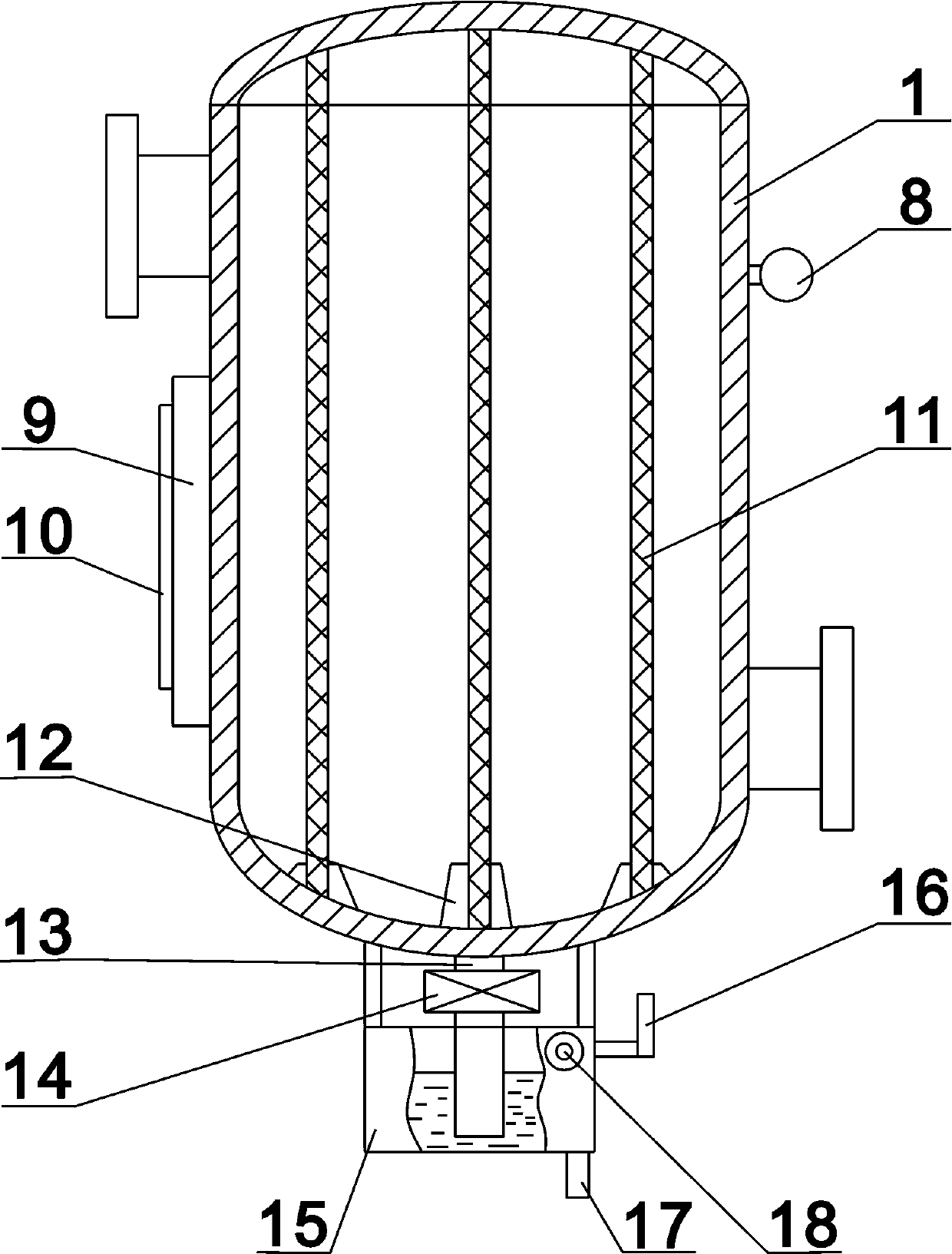

Chlorine buffer tank used for production of power cable

InactiveCN107842710AAvoid inhalationImprove filtering effectVessel mounting detailsDispersed particle filtrationParticulatesInterior space

The invention discloses a chlorine buffer tank for electric power cable production, which comprises a tank body, an upper cover, an air inlet pipe and an air outlet pipe. The upper cover, two hoisting rings are symmetrically installed on the top of the upper cover, the air inlet pipe is connected above the outside of the tank, the inlet flange is installed on the inlet pipe, the outlet pipe is installed under the outside of the tank, and the outlet flange is installed on the outlet pipe , A pressure detector for detecting the gas pressure inside the tank is installed on the side of the tank, the pressure detector is connected with the controller through an electrical signal, and the controller is installed on the side of the tank. This chlorine gas buffer tank for power cable production can not only buffer the chlorine gas, but also filter the fixed particles doped in the chlorine gas to obtain refined chlorine gas, which is convenient for the use of subsequent processes and can also reduce the pressure of the tank body. Real-time monitoring to avoid safety accidents caused by excessive pressure and reduce safety hazards.

Owner:洛阳虹雨电子技术有限公司

Method and apparatus for vaporizing liquid chlorine containing nitrogen trichloride

ActiveUS20120017848A1Safely evaporatePotent inhibitionNitrogen compoundsMachines/enginesHigh concentrationNitrogen

Owner:NORAM INT

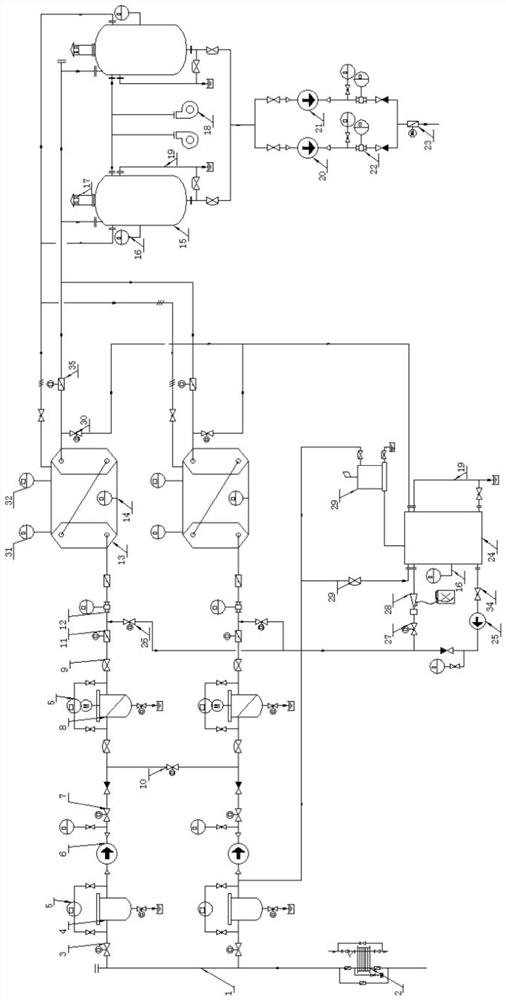

Raw seawater electrolysis chlorine production system and pickling method thereof

The invention relates to the technical field of seawater treatment, and provides a raw seawater electrolytic chlorine production system and an acid pickling method, the raw seawater electrolytic chlorine production system comprises a control system, a seawater supply system, a filtering system, an electrolytic chlorine production system, a storage hydrogen discharge system, a chemical dosing system and an acid pickling system, the control system is electrically connected with the seawater supply systems, the filtering system, the electrolytic chlorine production system, the storage hydrogen discharge system, the dosing system and the pickling system, the seawater supply systems are mutually standby through communication control valves, the seawater supply systems are connected with the electrolytic chlorine production system through the filtering system, and the storage hydrogen discharge system is connected with the pickling system. The output end of the electrolytic chlorine production system is connected with the input end of the storage hydrogen discharge system, the output end of the storage hydrogen discharge system is connected with the output end of the chemical feeding system, and the acid pickling system is connected with the electrolytic chlorine production system and forms an acid pickling loop with the electrolytic chlorine production system. And the system failure shutdown and maintenance cleaning frequency is reduced, and the automation degree is high.

Owner:TIANJIN SDIC JINNENG ELECTRIC POWER

Recycling device for chlorine-containing electrolytic waste gas

InactiveCN107475746AEasy to recycleExpand the range of suctionElectrolysis componentsWater storage tankEnvironmental engineering

The invention provides a recycling device for chlorine-containing electrolytic waste gas. The recycling device comprises an electrolytic chlorine generation tank, an electrolyte storage tank, an acidic water storage tank, a power supply device and a circulation pipeline, wherein the circulation pipeline is connected among the electrolytic chlorine generation tank, the electrolyte storage tank and the acidic water storage tank; the electrolytic chlorine generation tank comprises an anode chamber and a cathode chamber, and further comprises a chlorine circulation device; the chlorine circulation device is erected above the electrolytic chlorine generation tank; chlorine generated in the electrolytic chlorine generation tank is supplied to acidic electrolytic water through the chlorine circulation device; the chlorine circulation device comprises a gas capture device and a gas supply device; the gas capture device communicates with the anode chamber; and the gas supply device communicates with the interior of an acidic electrolytic water solution. Through the implementation of the above technical scheme, the economic loss and the environmental pollution which are caused by the diffusion of chlorine generated from electrolysis in the air can be avoided; and the sterilizing effect of a strongly acidic solution can be improved when chlorine is recycled.

Owner:弘毅天承知识产权股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com