Electrochemical ammonium micro-nano reactor, preparation method of anode material and ammonium removal application thereof

A micro-nano reactor and anode material technology, which is applied in chemical instruments and methods, other chemical processes, and water treatment parameter control, etc. Increased chlorine production efficiency, cost savings, and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

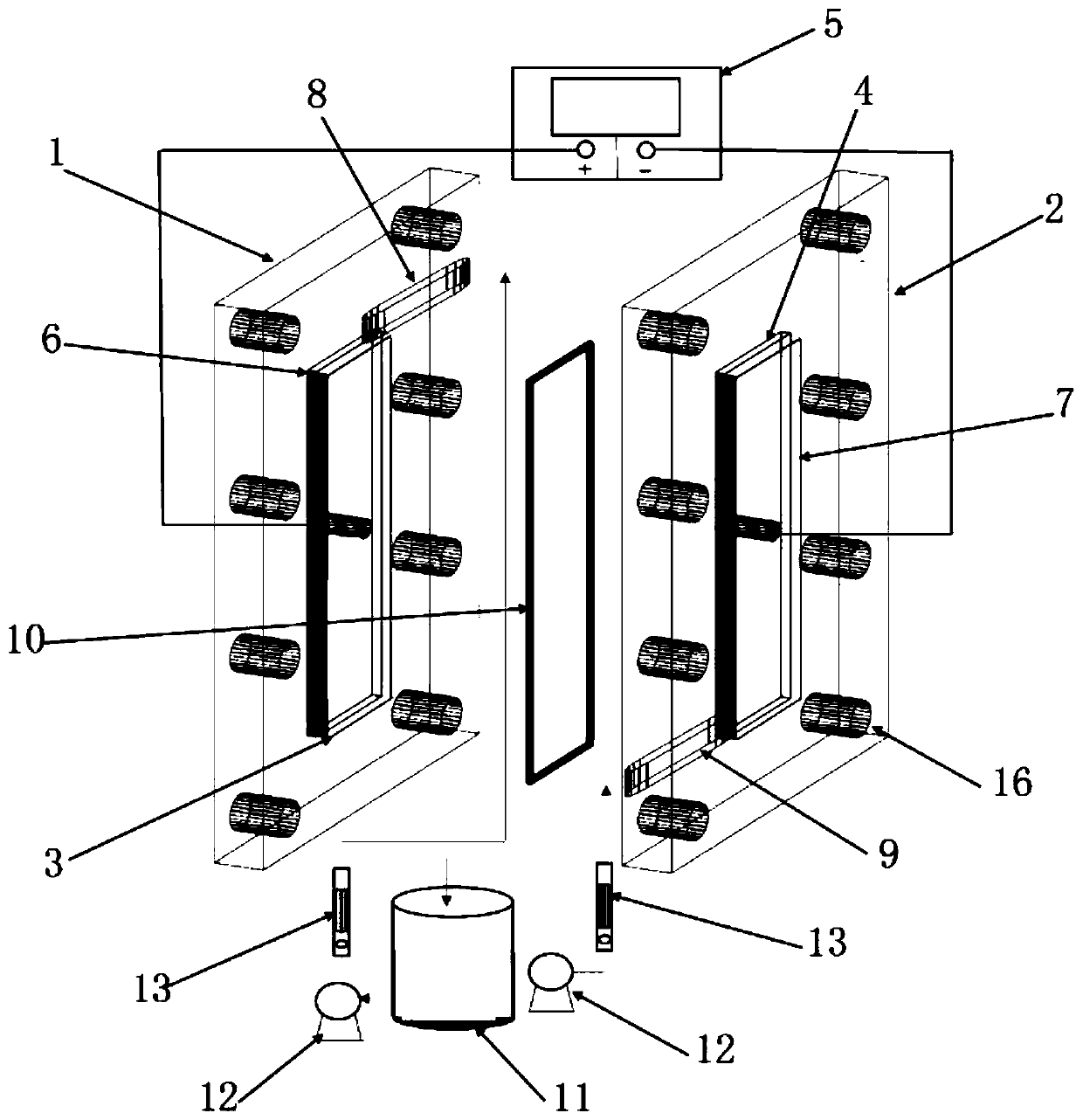

[0044] Such as figure 1 As shown, Embodiment 1 of the present invention provides an electrochemical ammonium micro-nano reactor, comprising:

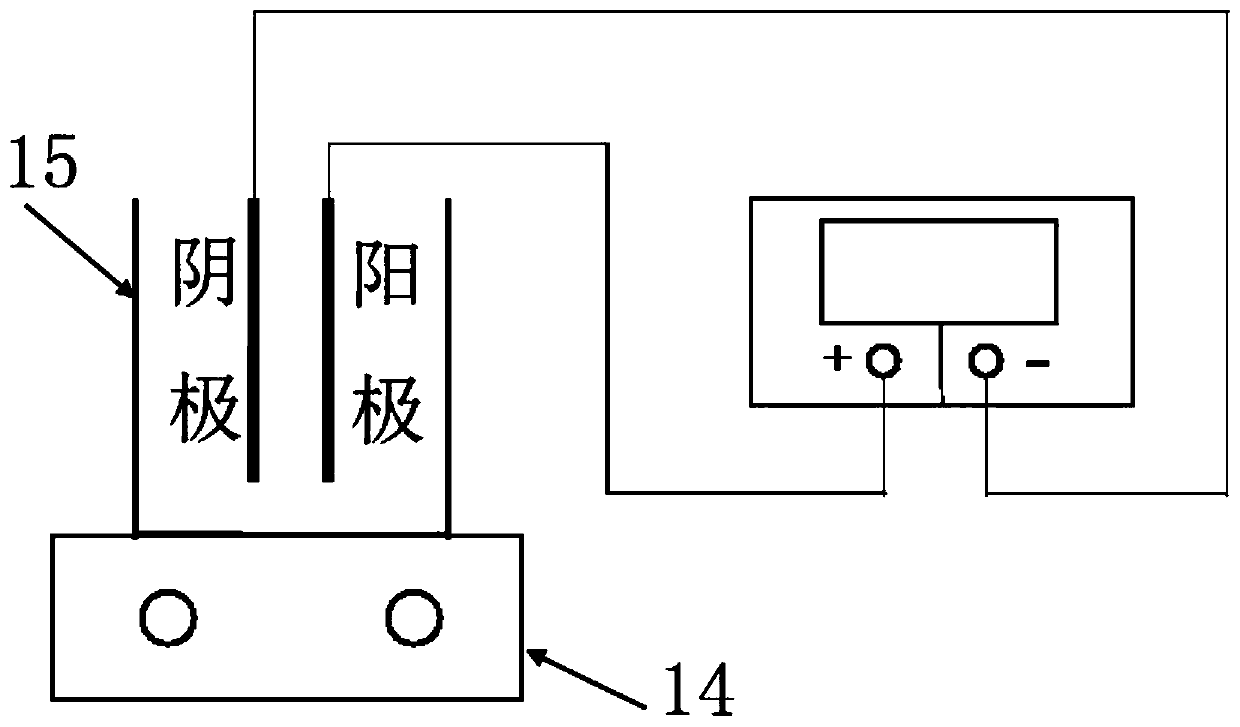

[0045] The first support plate 1, the second support plate 2, the anode material 3 and the cathode material 4, the anode material 3 and the cathode material 4 are respectively connected to the positive pole and the negative pole of the DC power supply 5;

[0046] The first support plate 1 is provided with a first groove 6, the anode material 3 is arranged in the first groove 6, and a gap is left between the anode material 3 and the bottom of the first groove 6 first space;

[0047] The second support plate 2 is provided with a second groove 7 corresponding to the first groove 6, and the cathode material 4 is provided in the second groove 7, and the cathode material 4 is connected with the first groove 7. There is a second space between the bottoms of the two grooves 7;

[0048] One side of the first supporting plate 1 is provided wit...

Embodiment 2

[0068] Embodiment 2 of the present invention provides an electrochemical anode material for deammonization of sewage. The electrochemical anode includes three functional materials, one of which is an ammonium ion sieve material (HEU crystal) with higher ammonium adsorption capacity after microwave treatment. type structure clinoptilolite), which can selectively exchange ammonium ions from water; one is a chloride ion adsorbent (hydrotalcite), which can adsorb chloride ions in water; one is a conductive support (activated carbon and acetylene black) .

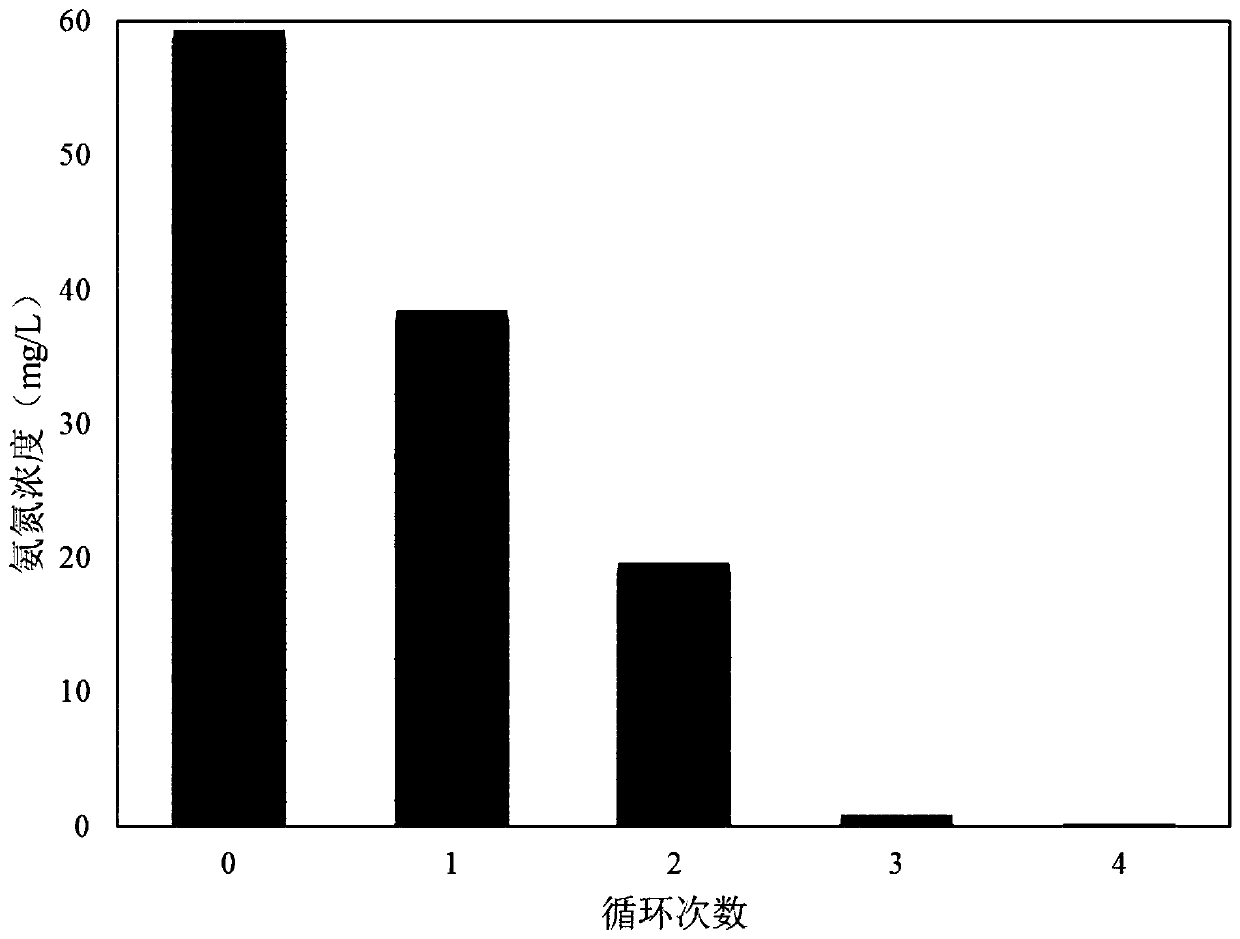

[0069] The working mechanism of the electrochemical anode material is as follows: First, the ammonium ion sieve material selectively exchanges ammonium ions from the water body, enriching the ammonium ions in the water body to the electrochemical anode; secondly, the chloride ion adsorbent on the electrochemical anode can Adsorb the chloride ions in the water body to its surface, making it in a high-concentration enrichment stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com