Chlorine buffer tank used for production of power cable

A technology for power cables and buffer tanks, used in electrical components, cable/conductor manufacturing, fixed-capacity gas storage tanks, etc., can solve problems such as the inability to improve the safety factor, the high pressure of the buffer tank, and the inability to remove them, so as to avoid safety accidents. , the effect of reducing potential safety hazards and simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

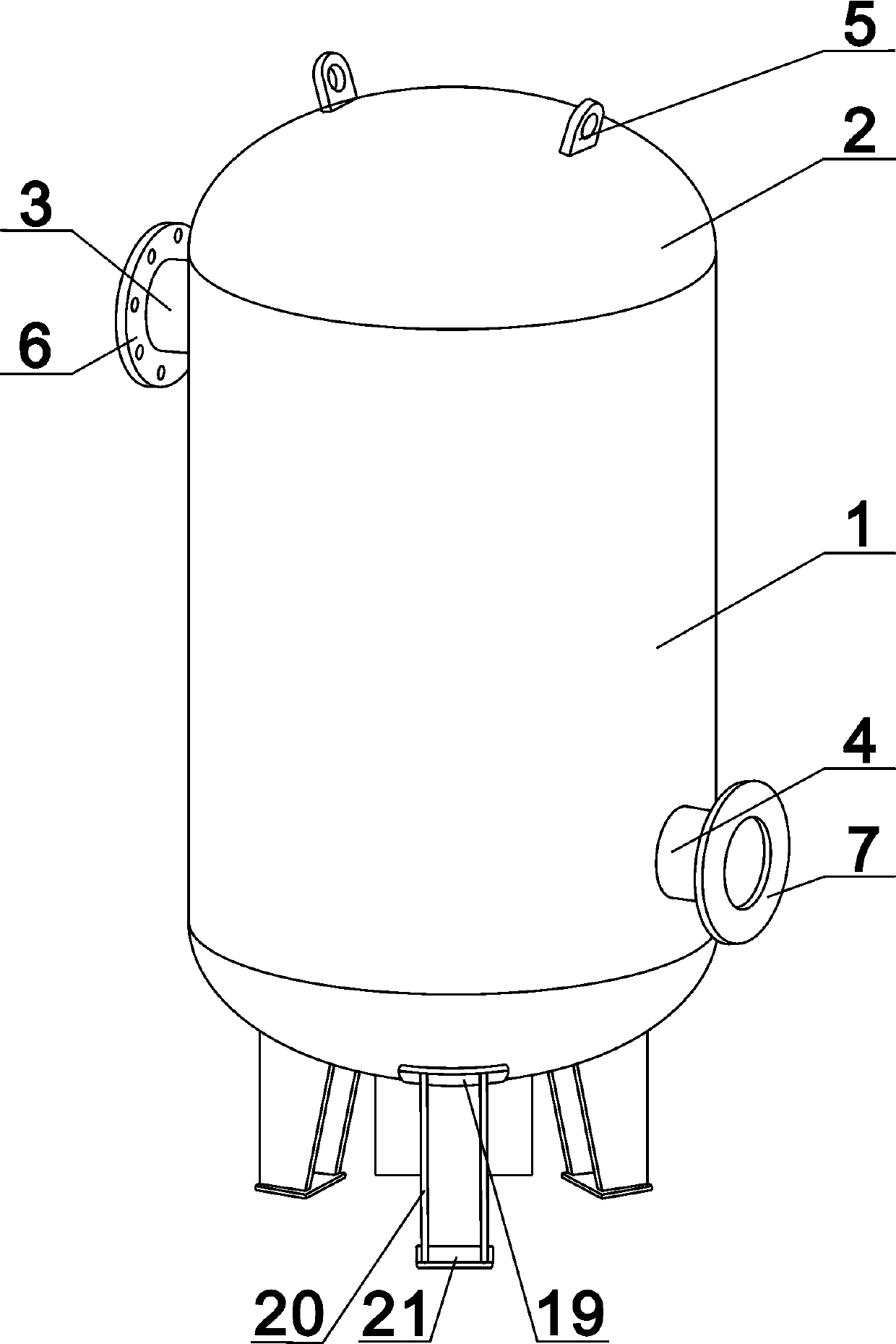

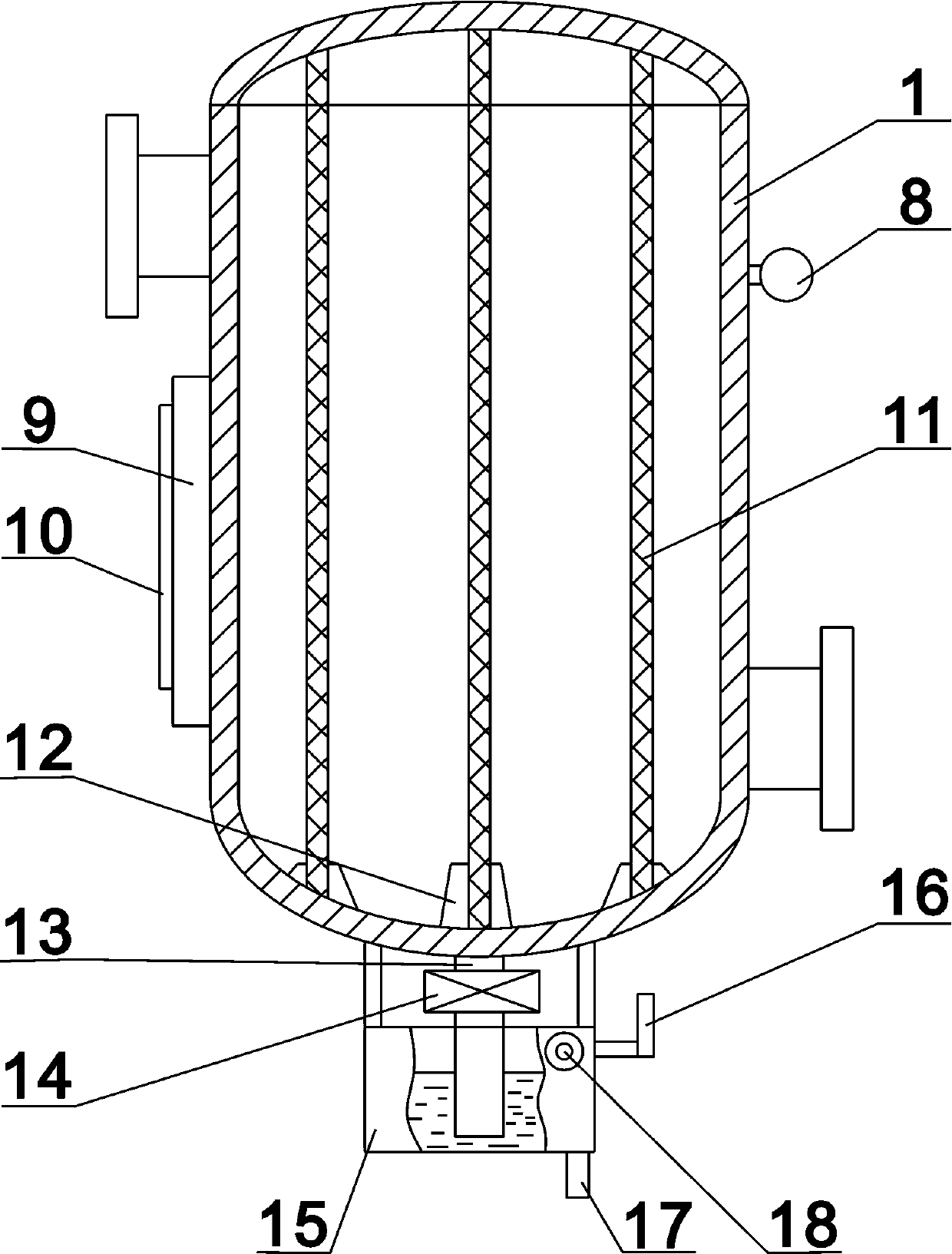

[0022] As shown in the figure, a chlorine buffer tank for power cable production includes a tank body 1, an upper cover 2, an air inlet pipe 3 and an air outlet pipe 4. The tank body 1 is a cylindrical structure, and the top of the tank body 1 is connected with a The upper cover 2 that seals the inner space of the tank body 1, two hoisting rings 5 are symmetrically installed on the top of the upper cover 2, the upper part of the tank body 1 is connected with an air inlet pipe 3, and an air inlet flange 6 is installed on the air inlet pipe 3, the tank body 1 An outlet pipe 4 is installed on the lower part of the exterior, and an outlet flange 7 is installed on the outlet pipe 4. A pressure detector 8 is installed on the side of the tank body 1 to detect the gas pressure inside the tank body 1. The pressure detector 8 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com