Swimming pool water chlorine production control method

A control method and production technology, applied in chemical variable control, non-electrical variable control, multiple fluid ratio control, etc., can solve problems such as adjustment of working gears without current, hidden dangers to human safety, and affecting the working time of pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

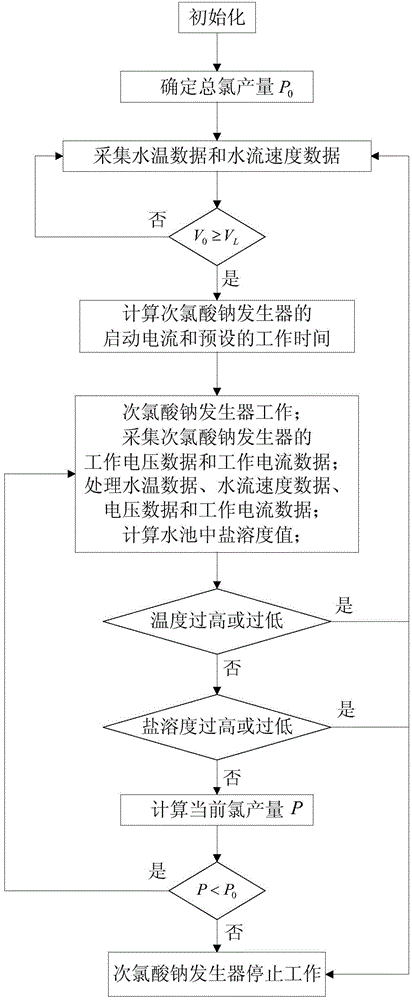

[0046] Such as figure 1 As shown, the method for controlling chlorine production in swimming pool water in this embodiment includes the following steps:

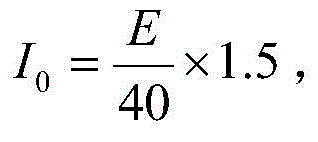

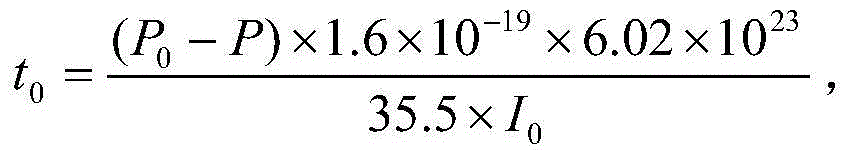

[0047] Step 1. Initialize, set the chlorine content M required for the swimming pool to achieve disinfection effect 0 3ppm, that is, the chlorine content required per cubic meter per day is 3 grams, set the initial salt concentration value C 0 3500ppm, set the minimum water flow velocity V in the pool L It is 2L / s. , The minimum number of data processing groups intercepted G, set the maximum working limit current I h , Set the maximum limit value PWM_T of the voltage control parameter PWM_Time to 65535;

[0048] Step 2: Determine the total chlorine production P required on the day the swimming pool reaches the disinfection effect 0 ;

[0049] The total chlorine production P required on the day the swimming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com