Zero-discharge system for quality-divided treatment of high-salinity wastewater of power plant

A technology for quality separation and high-salt wastewater treatment, applied in gaseous effluent wastewater treatment, seawater treatment, water/sewage treatment, etc., which can solve the problems of flue corrosion, increasing the difficulty of power plant disposal, and unclear national policies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

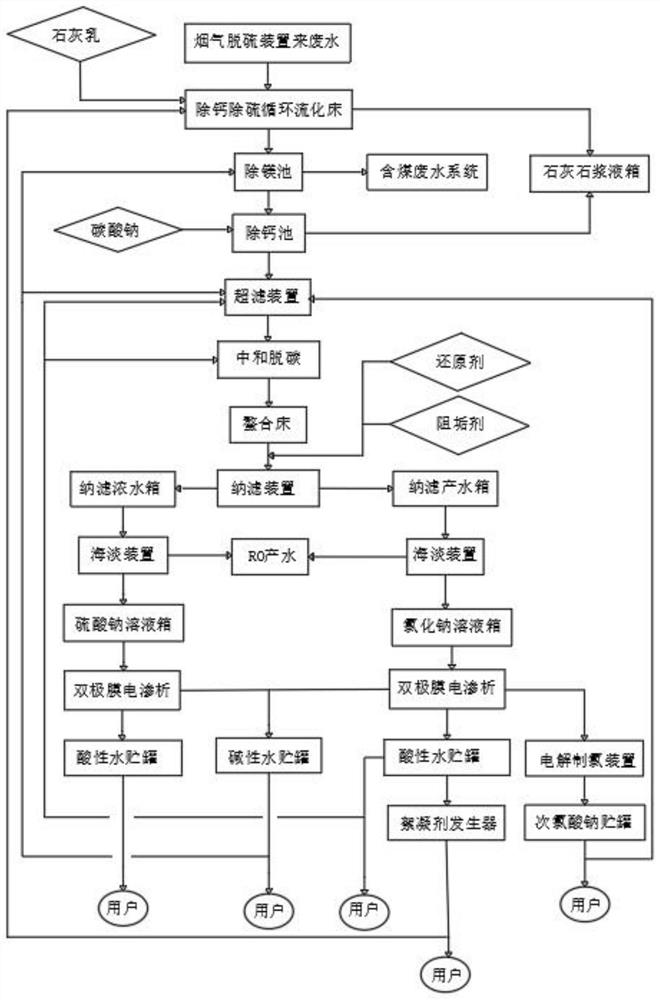

[0027] Such as figure 1 Shown is a zero discharge system for separate treatment of high-salt wastewater from a power plant, including a pretreatment system, a salt separation purification system, a regeneration system and a production system;

[0028] The pretreatment system includes a fluidized bed for calcium and sulfur removal, a magnesium removal pool, a calcium removal pool, an ultrafiltration unit, and a neutralization and decarburization pool;

[0029] Wastewater circulates in the decalcification and desulfurization fluidized bed, and lime milk and flocculant are added in the decalcification and desulfurization fluidized bed, and the calcium ions in the lime milk and the SO in the wastewater are combined with the lime milk and flocculant. 4 2- The reaction generates calcium sulfate precipitation, and the calcium sulfate flows into the limestone slurry tank after precipitation;

[0030] SO removal 4 2- The wastewater enters the magnesium removal tank, and alkaline wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com