Process for jointly obtaining a chlorine derivative and crystals of sodium carbonate

A technology of sodium carbonate and derivatives, which is applied in the field of joint acquisition of chlorine derivatives and sodium carbonate crystals, can solve problems such as power consumption, and achieve the effects of reducing emissions and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

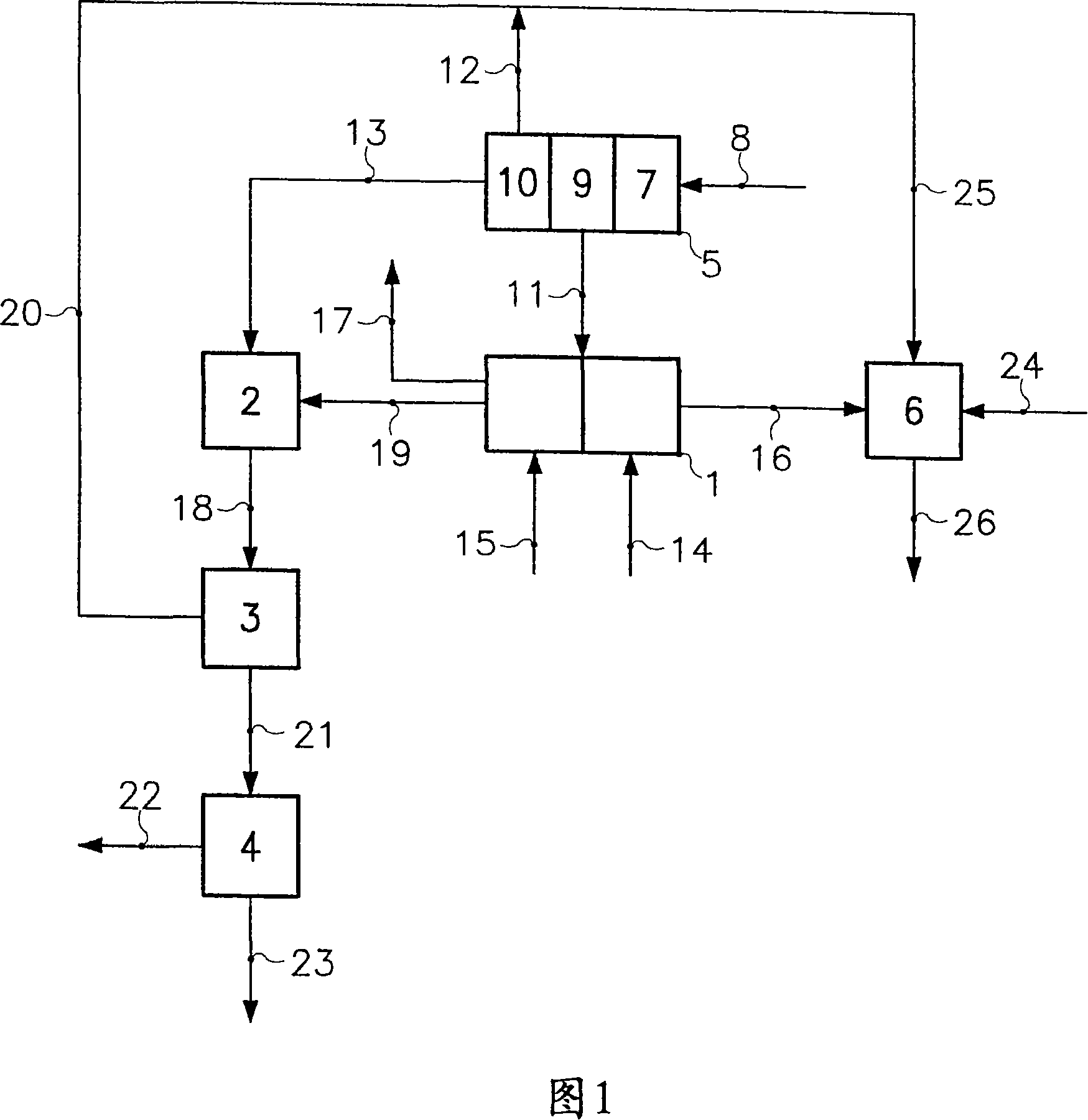

[0036] The device shown schematically in the figure includes an electrolytic cell (1), a carbonation tower (2), an evaporative crystallizer (3), a rotary drying chamber (4), a device for simultaneous electricity and steam generation (5) and vinyl chloride production unit (6).

[0037] The electrolytic cell (1) is a cation selective membrane type. It comprises an anode compartment and a cathode compartment separated from the anode compartment by a cation-selectively permeable membrane. Batteries can be unipolar or bipolar.

[0038] Cells with cation-selectively permeable membranes are well known in the field of electrolysis technology and are widely used for the industrial production of aqueous sodium hydroxide solutions from brine or aqueous sodium chloride.

[0039]The plant for simultaneous electricity and steam generation typically includes a gas turbine (7) fed with natural gas (8), an AC generator (9) and a boiler (10) fed with gas from the gas turbine. An AC generator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com