Desulfurization wastewater treatment system and method

A desulfurization wastewater and treatment system technology, applied in the direction of gaseous effluent wastewater treatment, dehydration/drying/thickened sludge treatment, water/sewage multi-stage treatment, etc., can solve the problem of high resource cost, improve treatment efficiency and reduce resources cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

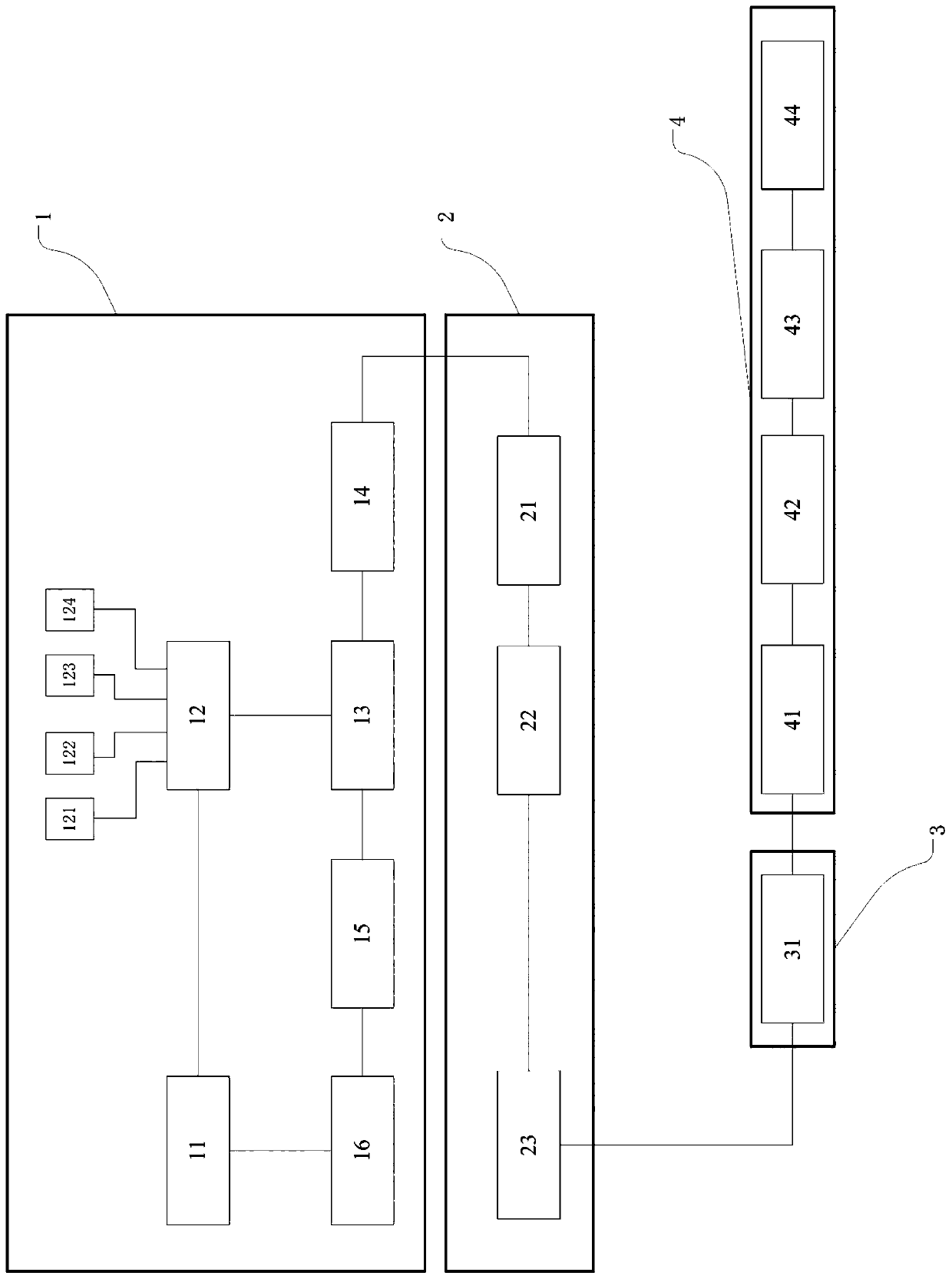

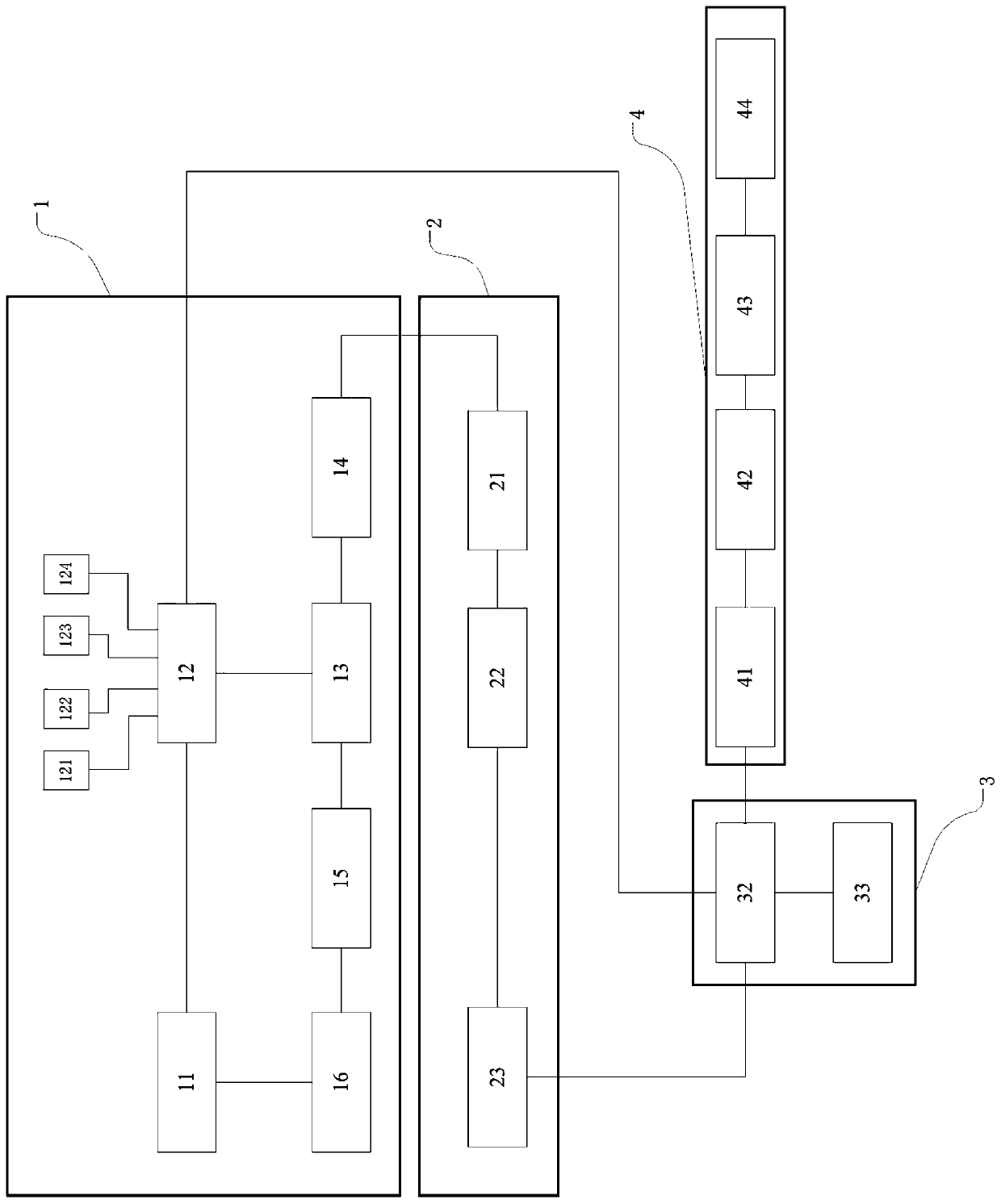

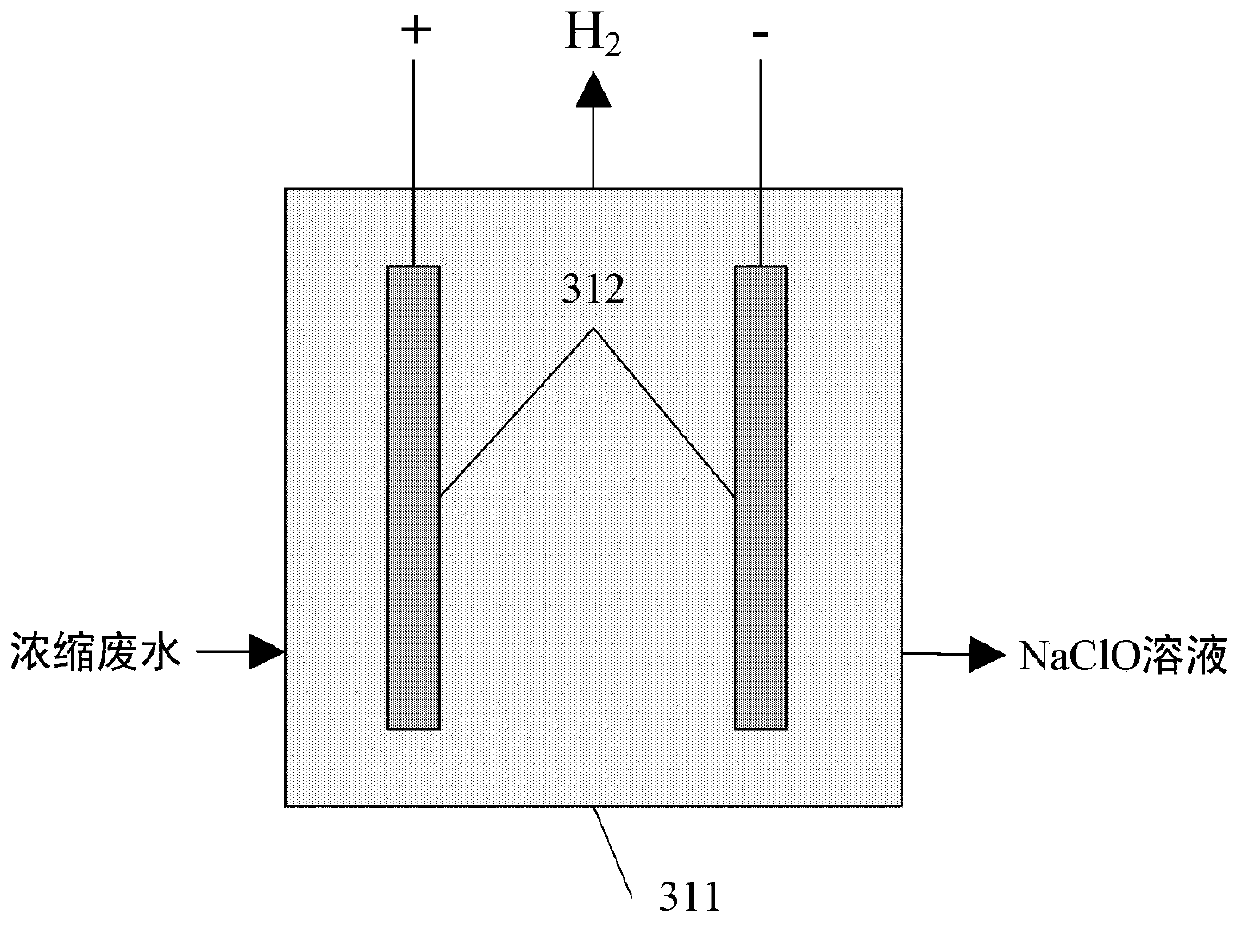

[0039] In a specific embodiment of the present invention, a desulfurization wastewater treatment system is provided, such as figure 1 , figure 2shown. The system consists of four units: softening pretreatment unit 1, membrane salt separation and concentration unit 2, electrolytic chlorine production unit 3 and hydrogen purification and recovery unit 4. The softening pretreatment unit includes a waste water collection tank 11, a triple box 12, a clarification tank 13, a tubular ultrafiltration device 14 and a supporting sludge collection tank 15, a dehydrator 16, a flocculant adding tank, and Medicine device 121, coagulant aid dosing device 122, softening agent dosing device 123 and scale inhibitor dosing device 124. The clarification tank 13 is connected to a dehydrator 16 through a sludge collection tank 15 , and the dehydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com