Raw seawater electrolysis chlorine production system and pickling method thereof

A control system, seawater technology, applied in electrolysis components, electrolysis process, cells, etc., can solve the problems of low degree of automation, poor operation reliability, poor cleaning effect, etc., to avoid electrode wear and blockage, reduce equipment investment cost, guarantee Effect of Electrode Life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

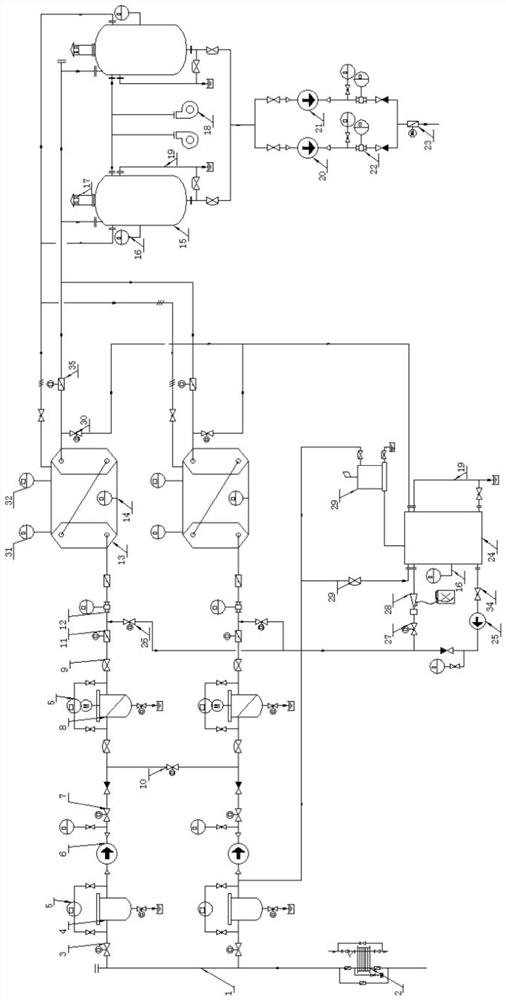

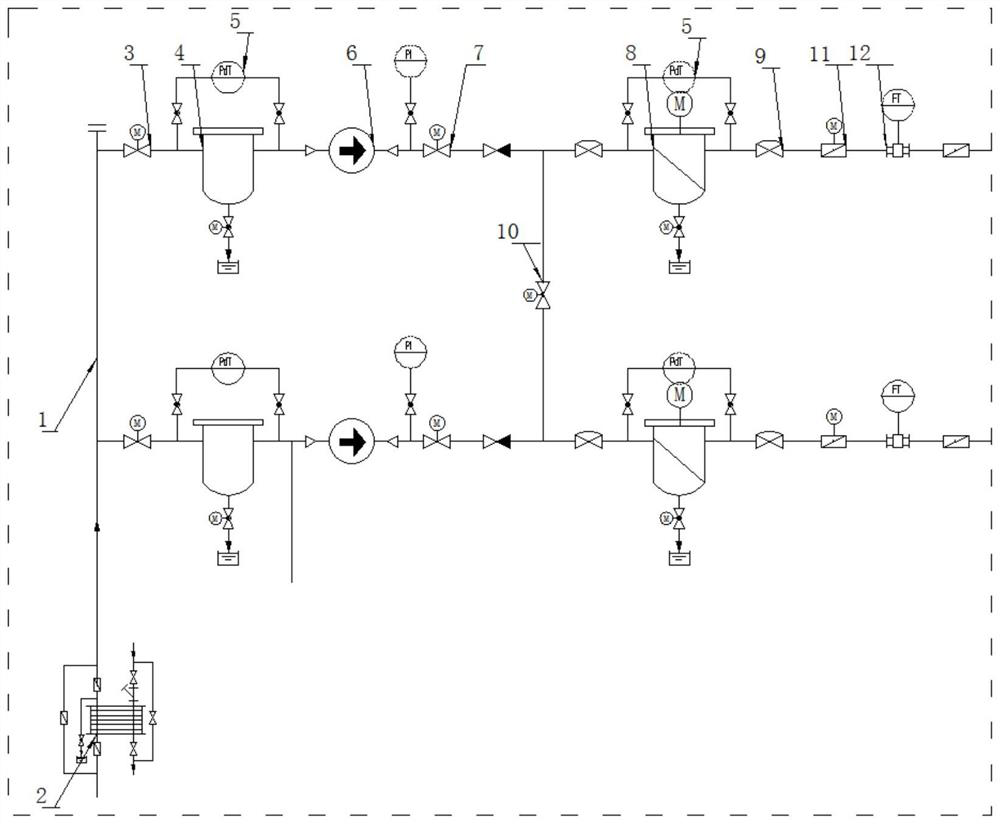

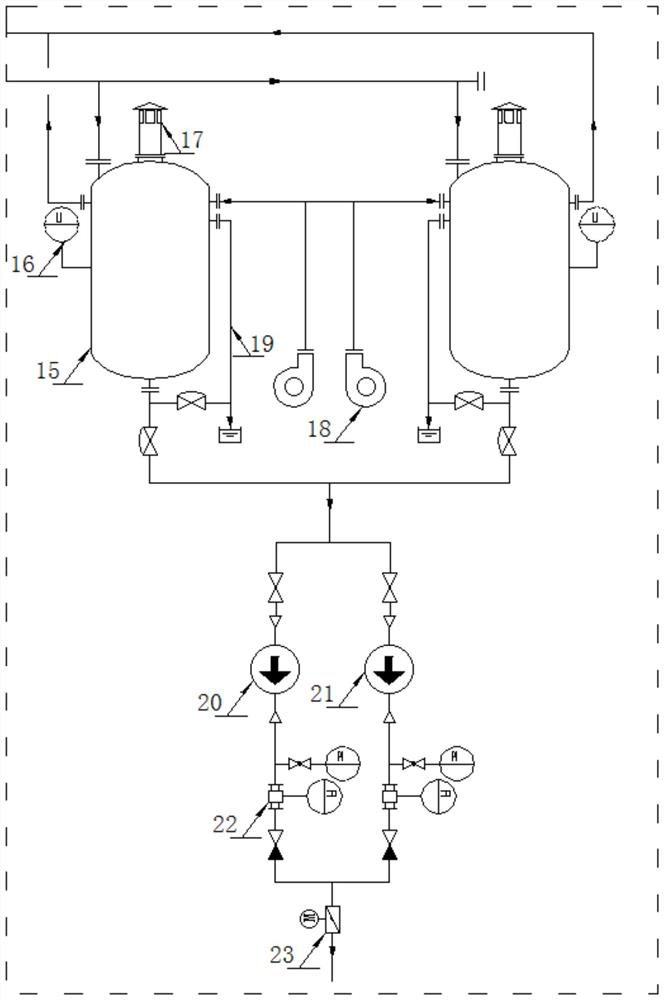

[0038] combine figure 1 To illustrate, an original seawater electrolytic chlorine production system includes: a control system, a seawater supply system, a filtration system, an electrolytic chlorine production system, a storage hydrogen discharge system, a dosing system and a pickling system, the control system is connected with the seawater supply system, Filtration system, electrolytic chlorine production system, storage hydrogen discharge system, dosing system and pickling system are electrically connected.

[0039] The seawater supply system is provided with at least two groups, and multiple groups of seawater supply systems are mutually backup through the liaison control valve 10, which can effectively ensure the safe and stable operation of the original seawater electrolytic chlorine production system, reduce the frequency of system failures and shutdowns, and the seawater supply system can pass through. The filtration system is connected with the electrolytic chlorine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com