Method used for combined production of hydrazine hydrate and calcium chloride by saponification slag

A technology of hydrazine hydrate and saponification slag, applied in the direction of calcium/strontium/barium chloride, nitrogen and non-metallic compounds, hydrazine, etc., to achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

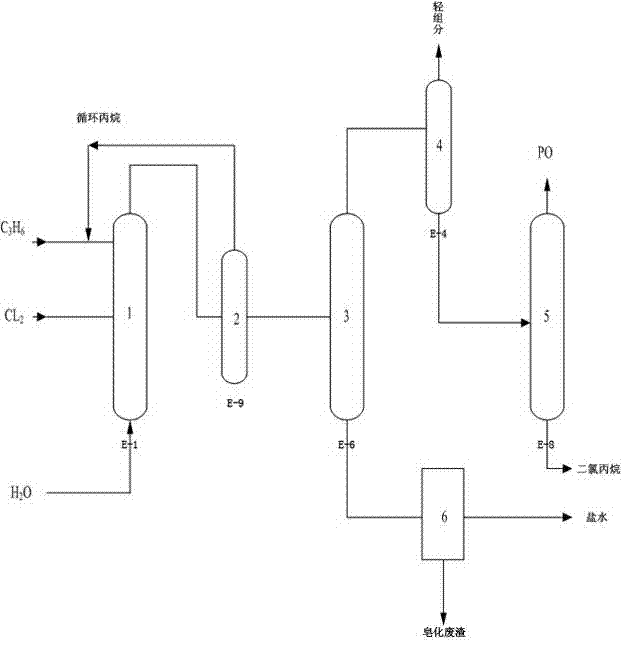

Image

Examples

preparation example Construction

[0029] 1 Preparation of hydrazine hydrate:

[0030] 1.1 Preparation of calcium hypochlorite:

[0031] CaCO and Ca(OH) in saponified slag are active ingredients. Saponification slag (particle size 40-60 mesh) is prepared with water to make a slurry with w% 20-30, the best is 25% concentration, chlorine gas is slowly passed into the prepared saponification slag slurry, the active ingredient reacts with chlorine gas to generate hypochlorous acid Calcium, the pH of the final control solution is 1-4, the best value is 2, so that the solution does not contain CO 2 , The available chlorine concentration in the obtained calcium hypochlorite feed liquid is 100g / l-200g / l.

[0032] 2CaCO 3 + 2Cl 2 =Ca(ClO) 2 + CaCl 2 + 2CO 2 ↑

[0033] 2Ca(OH) 2 + 2Cl 2 =Ca(ClO) 2 + CaCl 2 + 2H 2 o

[0034] Reduce the temperature of the resulting calcium hypochlorite to 0 0 C or so.

[0035] 1.2 Preparation of ferromolybdenum catalyst:

[0036] National standard i...

Embodiment

[0047] Catalyst preparation:

[0048] Weigh industrial pure ammonium dimolybdate ((NH 4 ) 2 Mo 2 o 7 , molecular weight 339.9527) and iron nitrate (Fe(NO3)3 9H2O

[0049] Molecular weight: 404.02) 8.5 kg and 13.47 kg, molecular ratio Mo:Fe=3:2, soluble in 85 kg and 81 kg in water respectively. Mix in a 50-liter enamel kettle with stirring and jacket, adjust the pH of the solution to 8 with nitric acid, start stirring, pass 90°C hot water into the jacket to raise the temperature of the material in the kettle to 75°C for 1 hour, stop heating, and pass cold water to make The material in the kettle was down to room temperature and left to stand for 5 hours. Dry at 120°C to constant weight, and then bake at 500°C for 4 hours to obtain about 6 kg of Mo-Fe catalyst, which is broken into particles with a particle size of 2-5mm.

[0050] Calcium hypochlorite preparation:

[0051] Add 600 kg of water to 1 cubic meter of enamel attached middle school with stirring, star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com