Electrode for electrolysis cell

一种电解槽、电极的技术,应用在电极领域,能够解决电极活性经济意义不理想等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The titanium mesh body with a size of 10 cm×10 cm was sandblasted with corundum, and the treated residue was cleaned by a compressed air jet. The pellets were then degreased using acetone in an ultrasonic bath for about 10 minutes. After the drying step, the flakes were heated at about 100°C in an atmosphere containing 250 g / l of NaOH and 50 g / l of KNO 3 Soak in aqueous solution for 1 hour. After the alkali treatment, the wafers were rinsed three times at 60° C. with deionized water, changing the liquid each time. A final rinse step was performed, adding a small amount of HCl (about 1 ml / l solution). to air dry, since the TiO x The formation of a brown tint was observed as the film grew.

[0022] 100 ml of a 1.3 M hydroalcoholic solution of a Ti-based precursor suitable for the deposition of a protective layer with a molar composition of 98% Ti, 1% Bi, 1% Nb was then prepared using the following components:

[0023] The 2M Ti hydroxyacetyl chloride complex solution...

Embodiment 2

[0041] The titanium mesh body with a size of 10 cm×10 cm was sandblasted with corundum, and the treated residue was cleaned by a compressed air jet. The pellets were then degreased using acetone in an ultrasonic bath for about 10 minutes. After the drying step, the flakes were heated at about 100°C in an atmosphere containing 250 g / l of NaOH and 50 g / l of KNO 3 Soak in aqueous solution for 1 hour. After the alkali treatment, the wafers were rinsed three times at 60° C. with deionized water, changing the liquid each time. A final rinse step was performed, adding a small amount of HCl (about 1 ml / l solution). to air dry, since the TiO x The formation of a brown tint was observed as the film grew.

[0042] 100 ml of a 1.3 M hydroalcoholic solution of a Ti-based precursor suitable for the deposition of a protective layer with a molar composition of 98% Ti, 2% Ta was then prepared using the following components:

[0043] The 2M Ti hydroxyacetyl chloride complex solution of 65m...

Embodiment 3

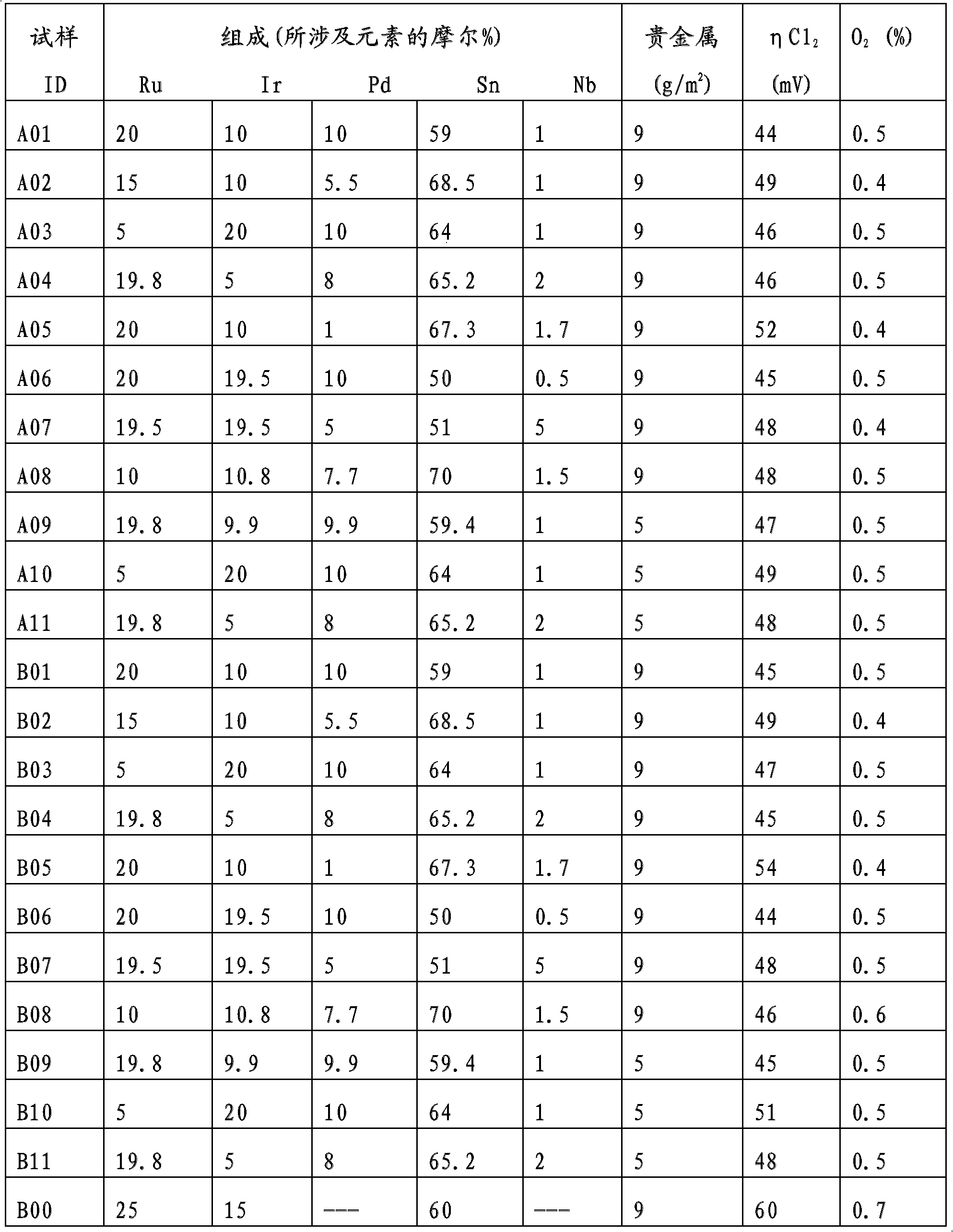

[0057] Starting from the above-mentioned pretreated titanium mesh sheets with dimensions of 10 cm x 10 cm, a series of samples labeled A02-A11 were prepared using the reagents and method as in Example 1, said sheets having a molar composition of 98% A protective layer of Ti, 1% Bi, 1% Nb, and a catalytic layer with the compositions reported in Table 1 and specific noble metal loadings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com