Preparation method of catalyst with core-shell structure for low-temperature fuel cell

A core-shell structure, fuel cell technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Large, large catalyst particle size and other problems, to achieve the effect of easy control of reaction conditions, short production cycle, cost and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

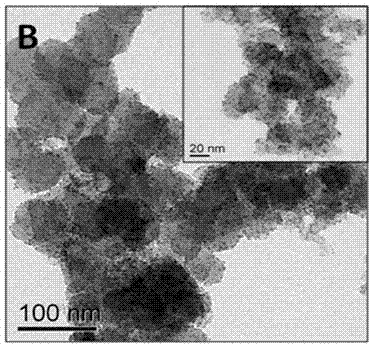

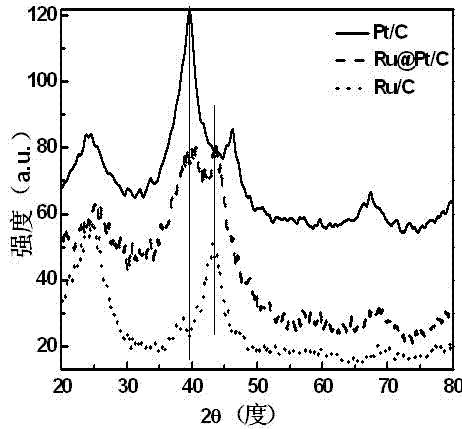

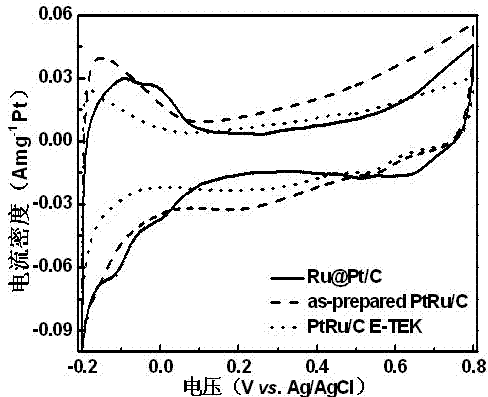

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 PdPt / C catalyst

[0045] Add 180mg of sodium citrate into 15mL of ethylene glycol (EG) solution, stir with magnetic force, and sonicate for more than 0.5h to dissolve completely. Then add 2.15mL PdCl dropwise to the solution 2 / EG (PdCl 2 The mass concentration is 20mg / ml) solution, after ultrasonication and stirring to mix evenly, then add pretreated 100mg VulcanXC-72 carbon black, after ultrasonication, stirring and mixing evenly, use 5%KOH / EG solution to adjust the pH of the solution to 9. Finally, transfer the obtained liquid to a high-pressure reactor and react at 160°C for 8 hours; after the reaction, cool to room temperature, adjust the pH value to 5 with dilute nitric acid aqueous solution with a mass concentration of 5%, and then wash with secondary water to No Cl was detected in solution - Until then, dry it in vacuum at 70°C to constant weight to obtain the catalyst precursor, that is, the Pd / C core;

[0046] The catalyst...

Embodiment 2

[0049] The preparation of embodiment 2 RuPt / C catalyst

[0050] Add 296 mg of sodium citrate into a mixed solution of 40 mL of glycerol and water (the volume ratio of glycerol to water is 3:1), stir magnetically, and ultrasonically sonicate for 0.5 hours each to completely dissolve the sodium citrate; then pour into the solution Add 5.3 mL of RuCl dropwise 3 / H 2 O solution (RuCl 3 The mass concentration of 20mgmL -1 ), ultrasonically and stirred evenly, then added 300 mg of oxidized Vulcan XC-72 carbon black, ultrasonically, stirred evenly, and then mixed with 5%KOH / H 2 O solution to adjust the pH value of the solution to 9, transfer the resulting liquid to a high-pressure reactor, and react at 160°C for 12 hours; after the reaction is completed, wait to cool to room temperature, wash with secondary water and filter the reaction system until no more is detected in the filtrate Cl - So far, the resulting filter cake was vacuum-dried at 80°C to a constant weight to obtai...

Embodiment 3

[0061] The preparation of embodiment 3 RuPt / C catalyst

[0062] Add 296mg of sodium citrate into the mixed solution of 40mL of glycerol and water (the volume ratio of glycerol to water is 3:1), stir magnetically, and sonicate for 0.5h each, then add 5.3mL of RuCl dropwise to the solution 3 / H 2 O solution (RuCl 3 The mass concentration is 20mgmL -1 ). After ultrasonic and stirring to mix evenly, add 300mg VulcanXC-72 carbon black after oxidation treatment, after ultrasonic mixing evenly, use 5%KOH / H 2 O solution, adjust the pH value of the solution to 9, then transfer the resulting liquid to an autoclave, and react at 160°C for 12 hours; after the reaction, cool to room temperature, wash with secondary water and filter the reaction in the autoclave liquid until no Cl was detected in the filtrate - So far, the resulting filter cake was vacuum-dried at 70 °C to constant weight to obtain a catalyst precursor (ie Ru / C core).

[0063] The catalyst precursor (Ru / C core) prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com