Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

A wastewater treatment and catalyst technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of insufficient removal of nitrogen-containing compounds and generation of mildew, and achieve high purification and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The method for preparing the catalyst of the present invention is not particularly limited, and the catalyst of the present invention can be easily prepared by known methods, for example, kneading method, impregnation method, adsorption method, spray method, ion exchange method and the like.

[0063] As described above, the catalyst of the present invention is characterized in that 70% by mass or more of the B component in the total amount of the B component is present in the surface layer from the outer surface of the oxide (catalyst) of the A component to a depth of 1000 μm or less. There is no particular limitation on the method of making most of the B component selectively exist in the surface layer of the oxide (catalyst) of the A component, as long as it is a method that allows the B component to exist in this way, the above-mentioned catalyst preparation method can be applied . The spraying method is preferable, and in particular, the method of spraying the aqueo...

Embodiment

[0158] The present invention will be described more specifically below by catalyst preparation examples, comparative preparation examples, examples and comparative examples, but the present invention is not limited to these examples.

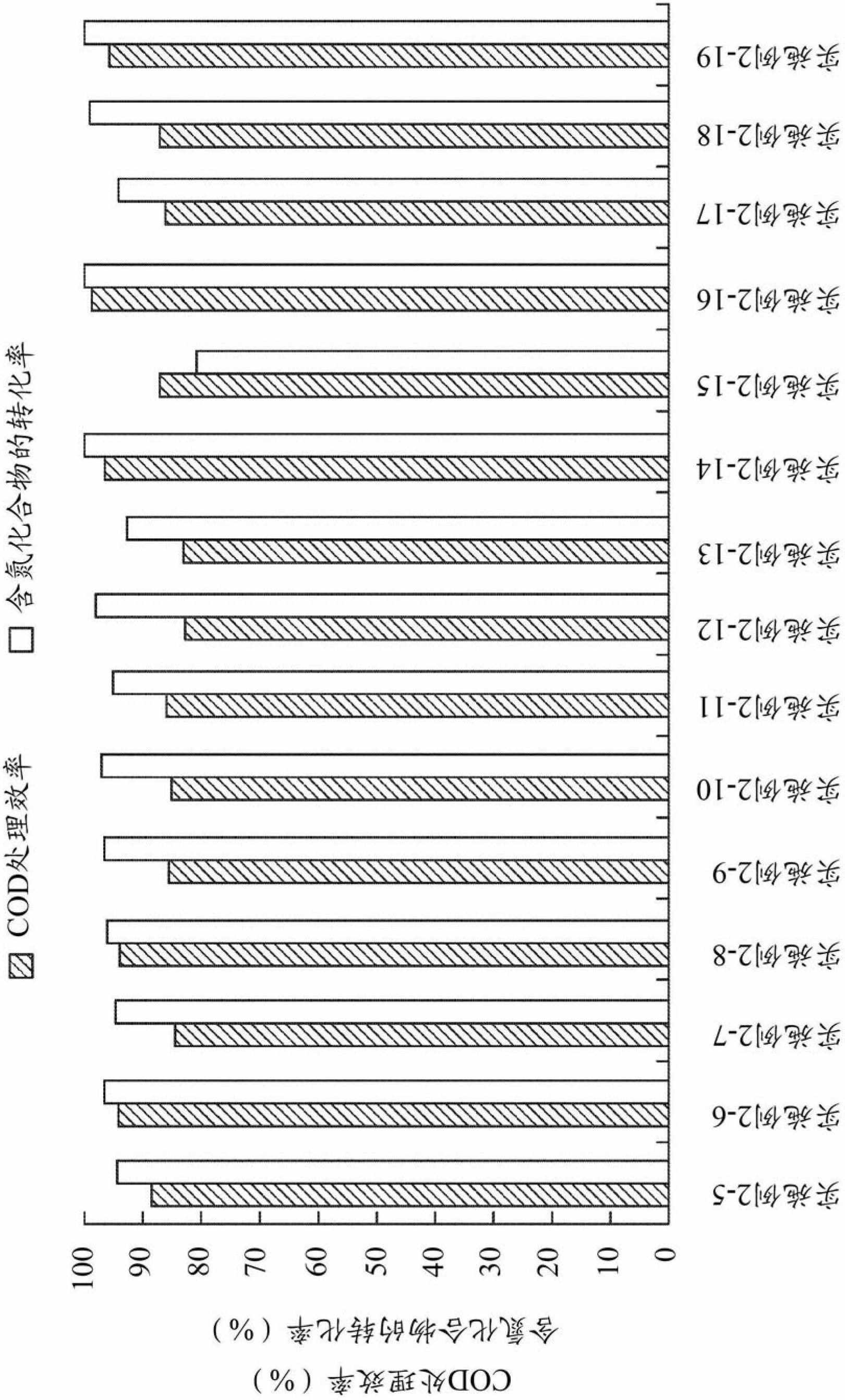

[0159] In the following examples, the total nitrogen concentration represents the total concentration of unreacted nitrogen-containing compounds, ammoniacal nitrogen, and nitrate nitrogen. Nitrate nitrogen is the general term for nitrogen oxide ions, such as NO 3 - , NO 2 - .

[0160] The distribution state of B component and the measuring method of the average particle diameter are shown below.

[0161] (Measurement of distribution state of component B)

[0162] The ratio (% by mass) of the B component present in the surface layer of the catalyst to 1000 μm from the outer surface of the catalyst to the total amount of the catalyst was obtained as follows: by EPMA (electron probe microanalysis), the catalyst in the cross section of the cata...

preparation example 1

[0190] Iron oxide (Fe) prepared by co-precipitation method 2 o 3 )-alumina (Al 2 o 3 ) powder is formed into flakes and loaded with platinum (Pt). The average diameter of the sheet is 5mm, the average length is 6mm, and the specific surface area is 58m 2 / g. In order to highly disperse and support Pt as fine particles on the surface of the sheet, spray a solution obtained by adding sodium carbonate to an alkaline platinum complex aqueous solution while moving the sheet, and allow it to be supported. After the sheet was dried for 1 hour while rotating it in a hot air stream at 90° C., a reduction treatment was performed at 300° C. for 3 hours using a hydrogen-containing gas to obtain a catalyst (A-1). The mass ratio of the main component of the catalyst obtained is Fe 2 o 3 :Al 2 o 3 :Pt=90:9.7:0.3. In addition, the results of the investigation of the Pt distribution of catalyst A-1 (the ratio of Pt existing within 1000 μm from the surface of the substrate to the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com