Landfill leachate treatment process system and method

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment process systems, can solve the problems of increasing economic burden and difficulty in meeting discharge standards, and achieve the effects of achieving biodegradability, solving effluent chroma, and controlling treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

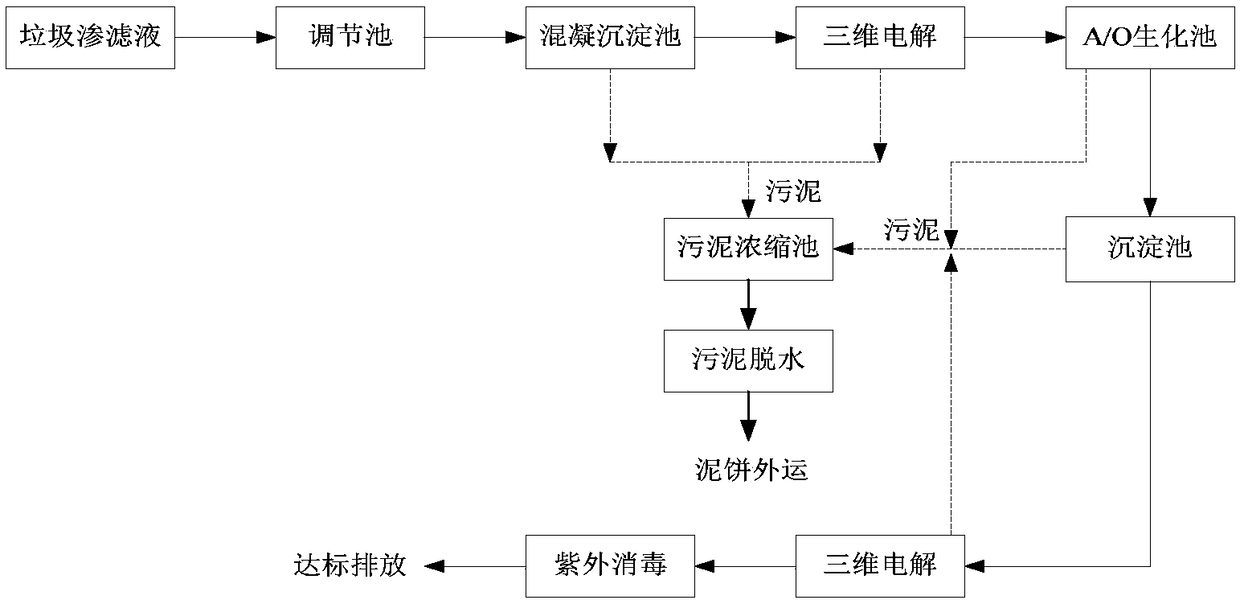

Method used

Image

Examples

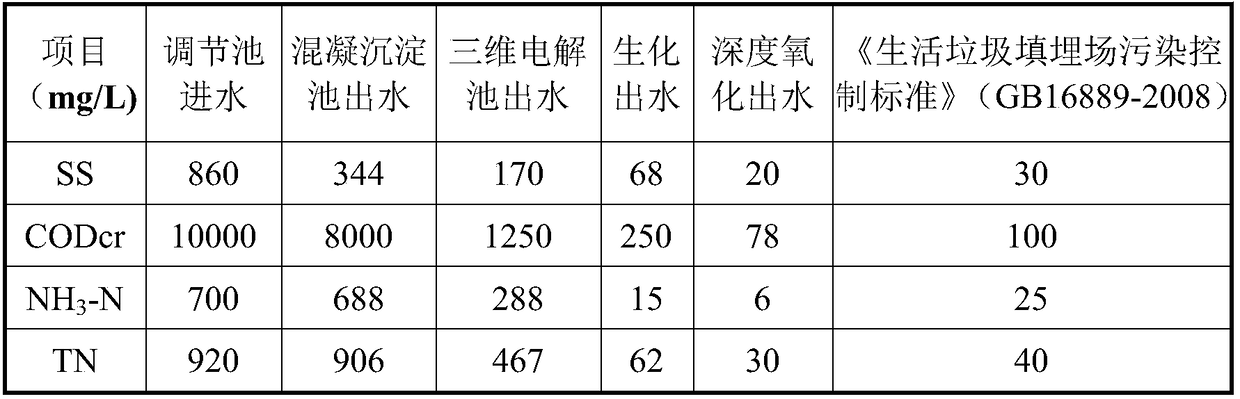

Embodiment 1

[0049] (1) Garbage leachate (COD value is 10000, ammonia nitrogen value is 700) flows into the adjustment tank by itself, in the adjustment tank, the water volume is controlled by the liquid level gauge to 50L / h, and the stirring device is added to realize the homogenization of water quality, and the degradable part of COD and ammonia nitrogen;

[0050] (2) The wastewater from the adjustment tank flows into the coagulation sedimentation tank, first adjust the pH value of the wastewater to 5.5, add the coagulant as polyaluminium chloride, and the dosage is 2.5g / L; the coagulant aid is polypropylene Amide, the dosage is 1.0mg / L, after mixing evenly, it precipitates;

[0051] (3) The coagulation and sedimentation effluent flows into the three-dimensional electrolytic cell to oxidize the organic pollutants in the wastewater. The electrodes in the three-dimensional electrolysis device use stainless steel as the anode, graphite as the cathode, the distance between the electrodes is...

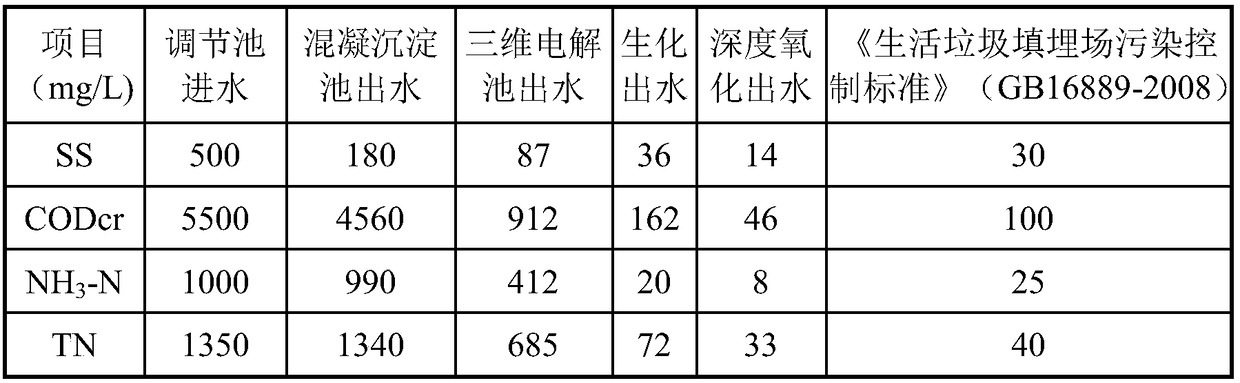

Embodiment 2

[0057] (1) Garbage leachate (COD value is 5500, ammonia nitrogen value is 1000) flows into the adjustment tank by itself, in the adjustment tank, the water volume is controlled by the liquid level gauge to 50L / h, and the stirring device is added to realize the homogenization of water quality, and the COD of the degradable part and ammonia nitrogen;

[0058] (2) The wastewater from the adjustment tank flows into the coagulation sedimentation tank, first adjust the pH value of the wastewater to 5.5, add the coagulant as polyaluminum chloride, and the dosage is 2.0g / L; the coagulant aid is polypropylene Amide, the dosage is 0.8mg / L, after mixing evenly, it precipitates;

[0059] (3) The coagulation and sedimentation effluent flows into the three-dimensional electrolytic cell to oxidize the organic pollutants in the wastewater. The electrodes in the three-dimensional electrolysis device are made of stainless steel as the anode and graphite as the cathode, the distance between the...

Embodiment 3

[0065] (1) Garbage leachate (COD value is 2850, ammonia nitrogen value is 1560) flows into the adjustment tank by itself, in the adjustment tank, the water volume is controlled by the liquid level gauge to 50L / h, and the stirring device is added to realize the homogenization of water quality, and the COD of the degradable part and ammonia nitrogen;

[0066] (2) The wastewater from the adjustment tank flows into the coagulation sedimentation tank, first adjust the pH value of the wastewater to 5.5, add the coagulant as polyaluminium chloride, and the dosage is 1.0g / L; the coagulant aid is polypropylene Amide, the dosage is 0.8mg / L, after mixing evenly, it precipitates;

[0067] (3) The coagulation and sedimentation effluent flows into the three-dimensional electrolytic cell to oxidize the organic pollutants in the wastewater. The electrodes in the three-dimensional electrolysis device use stainless steel as the anode, graphite as the cathode, the distance between the electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com