Device for absorbing hydrogen chloride in hydrogen chloride catalytic oxidation chlorine production process gas

A catalytic oxidation and absorption device technology, applied in chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, inorganic chemistry, etc., can solve problems such as poor effect, different corrosion degrees, and increased device costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

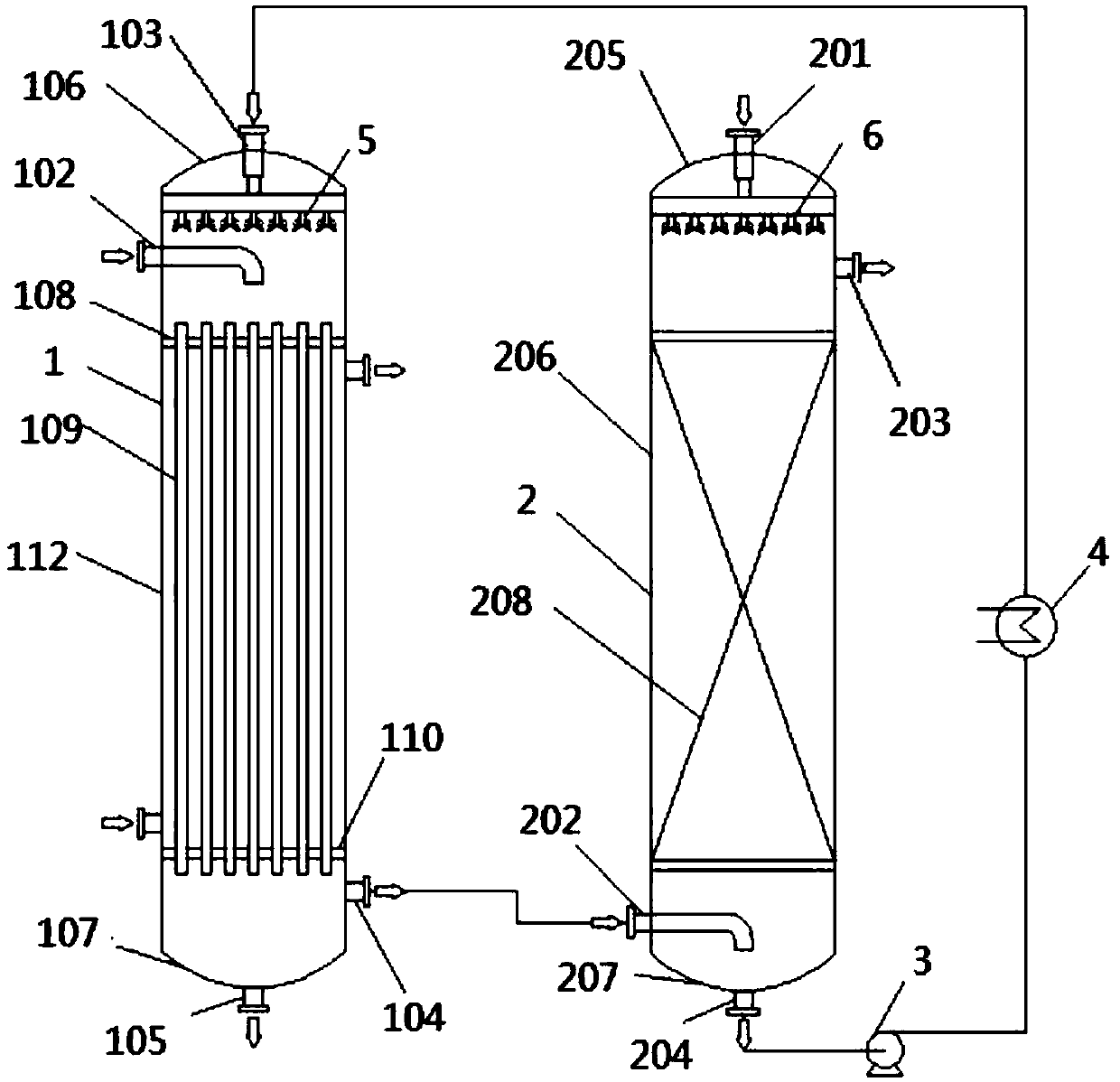

[0013] Such as figure 1 As shown, the hydrogen chloride absorption device includes a falling film absorber 1, a packed tower 2, a hydrochloric acid pump 3 and a graphite heat exchanger 4;

[0014] The materials of process gas inlet 102, dilute acid inlet 103, process gas outlet 104 after primary absorption, and condensate outlet 105 of the falling film absorber are tantalum;

[0015] The absorption water inlet 201 of the packed tower, the process gas inlet 202 after primary absorption, the process gas outlet 203 after secondary absorption and the dilute acid outlet 204 are made of tantalum;

[0016] The upper head 106 of the falling film absorber, the lower head 107 of the falling film absorber, the upper head 205 of the packed tower, the cylinder body 206 and the lower head 207 are made of steel-lined silicone impregnated impermeable graphite;

[0017] The material of the fixed tube sheet 108, absorption tube 109, and floating tube sheet 110 of the falling film absorber is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com