Supercritical carbon dioxide fluid extraction industrial equipment manufacturing device and manufacturing method

A carbon dioxide, manufacturing device technology, applied in solid solvent extraction, chemical instruments and methods, solvent extraction and other directions, can solve the problems of unsuitable manufacturing of large-capacity pressure vessels, low high pressure resistance of stainless steel, etc. The effect of expanding capacity and convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

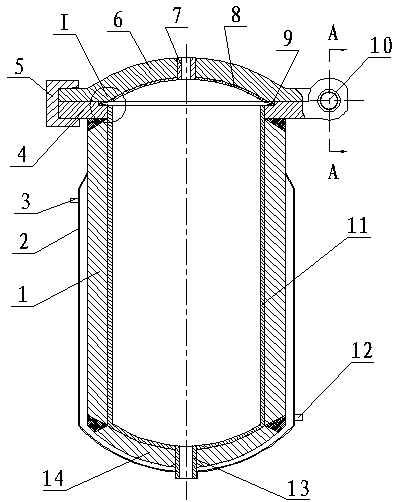

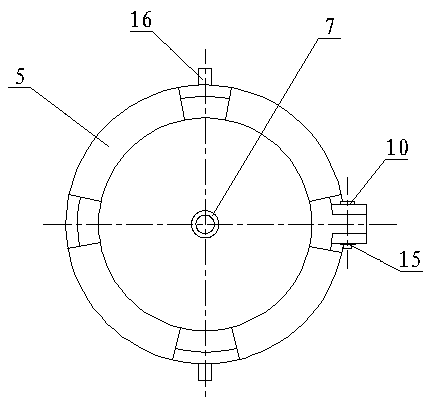

[0026] A supercritical carbon dioxide fluid extraction industrial equipment manufacturing device, which comprises: a steel pipe 1, the top and bottom of the steel pipe are respectively welded to the lower flange 4 and the semicircular head 14 to form a kettle body, and the lower The flange is connected to the upper cover 6 through the connecting shaft 10, the lower flange and the upper cover are fixed by four clamps 5, and a lip seal is installed between the lower flange and the upper cover 9. The inner wall of the upper cover has a stainless steel layer 8, the top of which is welded with a stainless steel sleeve A7, the inner wall of the kettle body has a stainless steel layer 11, the bottom of the kettle body is welded with a stainless steel sleeve B13, and the outer side of the kettle body The enclosure 2 is fixed.

Embodiment 2

[0028] According to the supercritical carbon dioxide fluid extraction industrial equipment manufacturing device described in Example 1, the cavity formed by the coaming plate and the kettle body is a water heating layer, and a water inlet pipe 3 is installed on the upper left side of the coaming plate , a water outlet pipe 12 is installed under the right side of the coaming plate, the four clamps are evenly arranged in the circumferential direction, two opening supports 16 are respectively arranged between the two clamps, and the upper The stainless steel coating on the inner wall of the lid and the stainless steel coating on the inner wall of the kettle are respectively 1.0 mm thick.

Embodiment 3

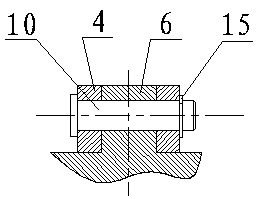

[0030] According to the supercritical carbon dioxide fluid extraction industrial equipment manufacturing device described in embodiment 1 or 2, the right side of the upper cover has a lug A, and the lower flange has a lug B with a groove, and the The lug A is installed in the groove of the lug B, the connecting shaft passes through the lug A and the lug A and is fixed by the snap ring 15, the steel pipe, the upper cover, and the lower method The blue plate is carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com