Die water path cleaning device

A cleaning device and mold technology, applied in water/sewage treatment, water/sludge/sewage treatment, filtration treatment, etc., can solve problems such as damage to the inner surface of the mold, improve cleaning quality, save time and labor costs, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

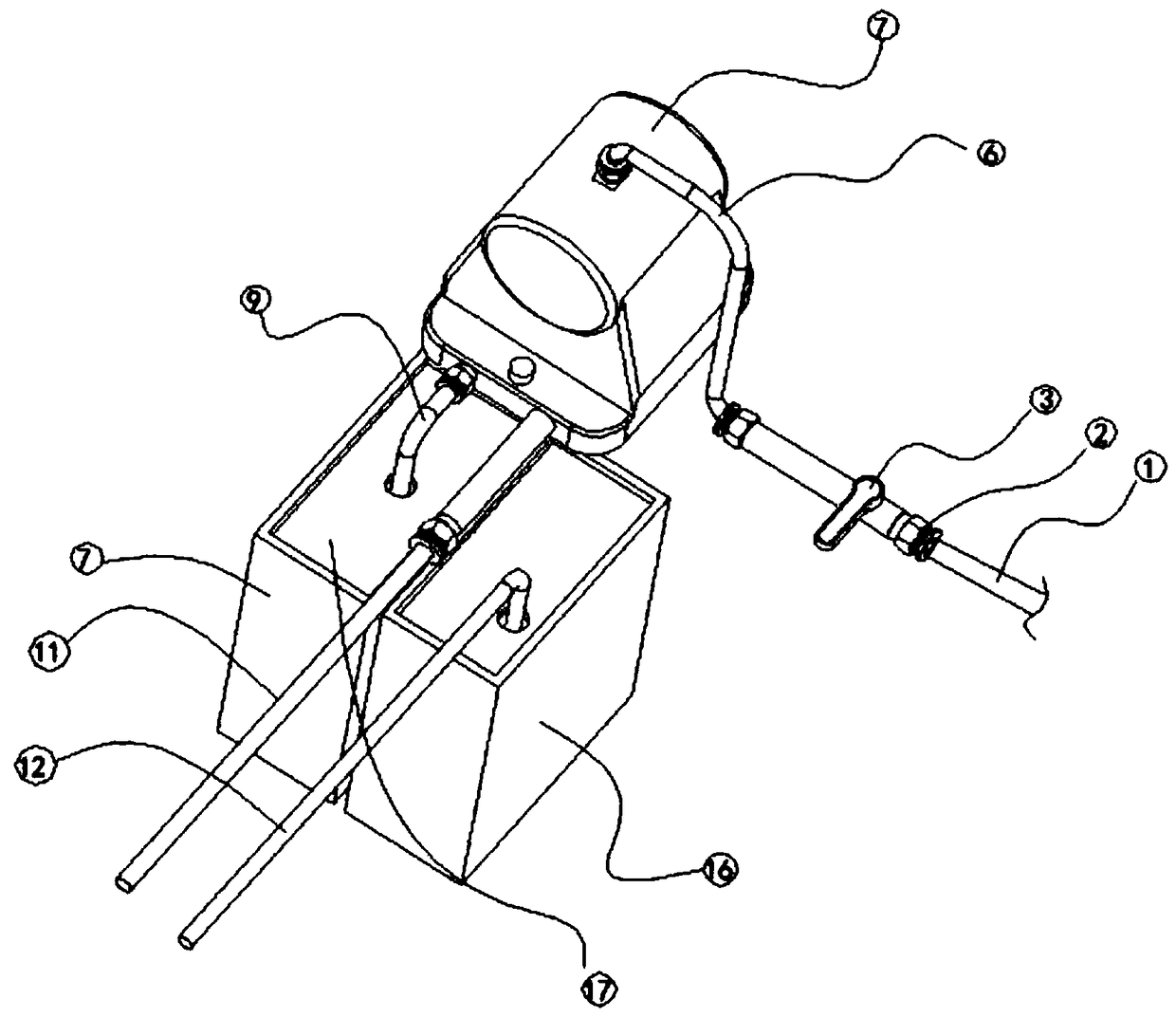

[0049] like figure 1 Shown, a kind of mold waterway cleaning device of the present invention comprises:

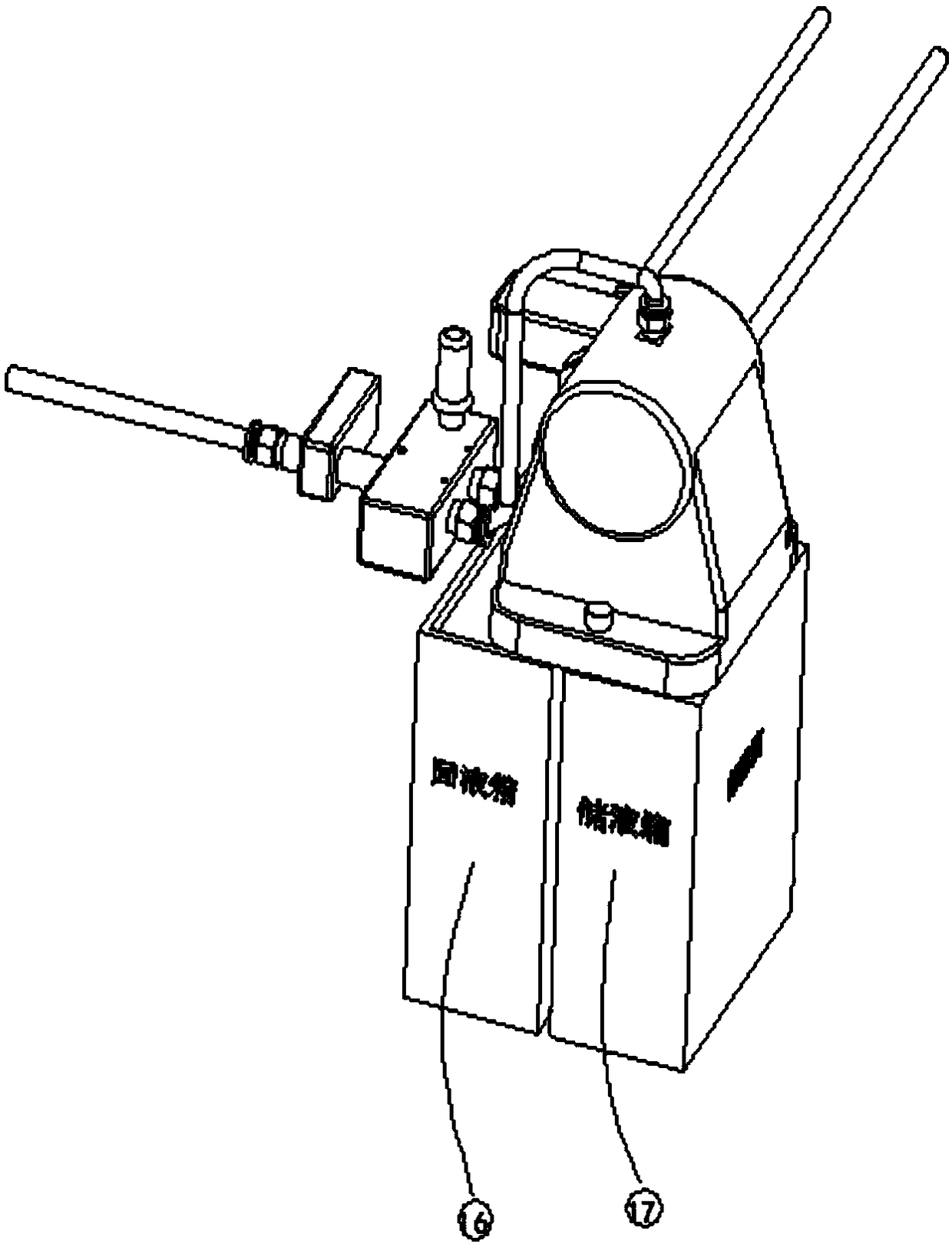

[0050] The liquid storage tank 17 is used to store the cleaning liquid;

[0051] The liquid return tank 16 is used to recover the cleaning liquid;

[0052] pump assemblies, including pumps;

[0053] The first liquid inlet pipe 9, its first end communicates with the liquid storage tank 17, and its second end communicates with the liquid inlet port of the pump;

[0054] The second liquid inlet pipe 11, its first end communicates with the liquid outlet of the pump, and the second end is suitable for connecting with the mold water inlet pipe joint;

[0055] The first end of the liquid return pipe 12 is suitable for connecting with the mold outlet pipe joint, and the second end is suitable for communicating with the liquid return tank 16 .

[0056]By arranging the liquid storage tank 17 and the liquid return tank 16, it is possible to prevent the cleaned cleaning liquid fro...

Embodiment 2

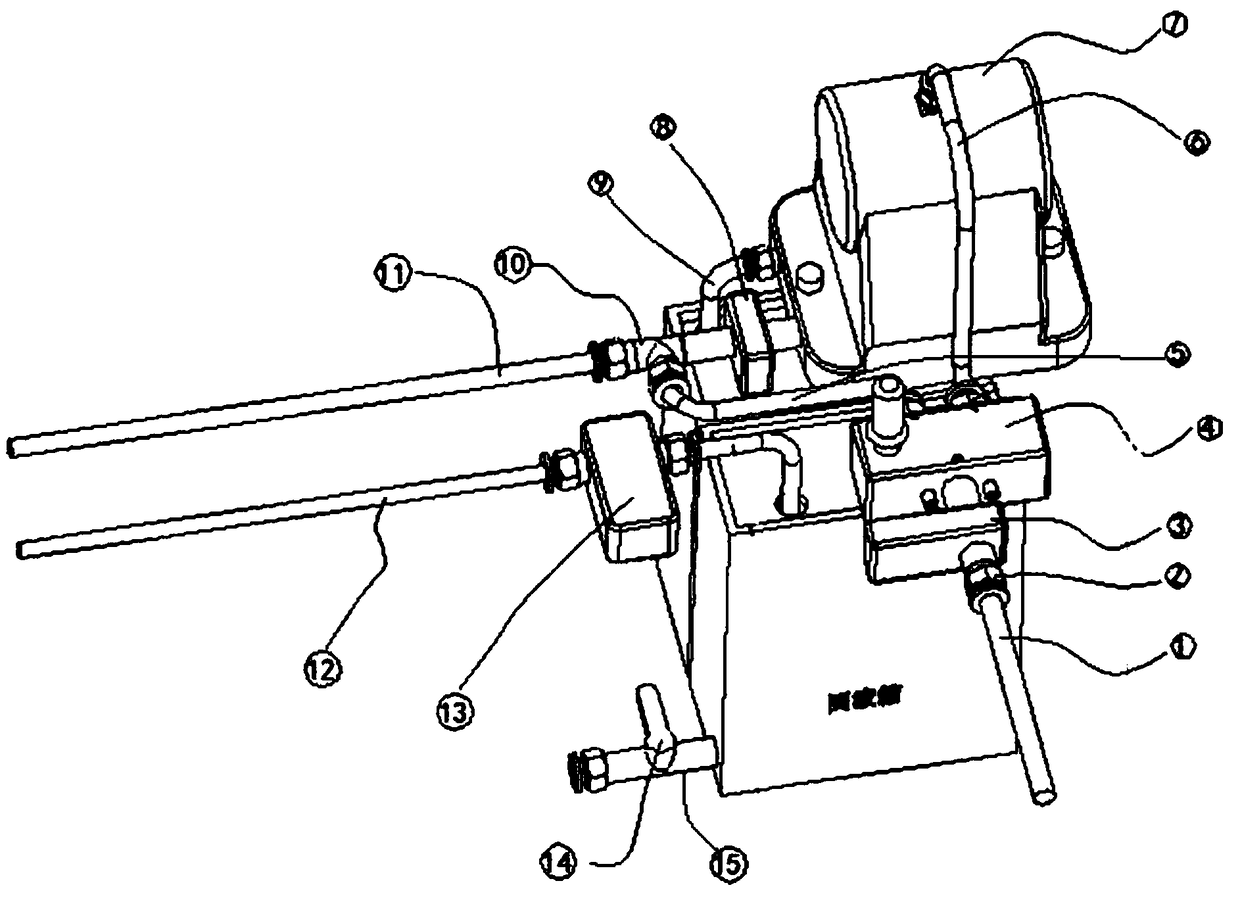

[0066] like Figure 2-4 As shown, on the basis of Embodiment 1, this implementation 2 also includes a blowing pipeline structure, and the blowing pipeline structure includes

[0067] A three-way joint 10 is arranged on the second liquid inlet pipe 11;

[0068] The liquid outlet valve 8 is arranged on the second liquid inlet pipe 11 and is located between the three-way joint 10 and the air-controlled pump;

[0069] An air supply pipeline assembly, one end communicates with the tee joint 10, and the other end communicates with the compressed air source;

[0070] When cleaning the mold, control the air supply pipeline assembly to cut off the air supply to the second liquid inlet pipe 11, and control the opening of the inlet valve 3 and the opening of the liquid outlet valve 8;

[0071] When drying the mold, control the liquid outlet valve 8 to close, and control the air supply pipeline assembly to communicate with the second liquid inlet pipe 11 to supply air.

[0072] Due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com