Reactor for chlorine production and process for producing chlorine

A reactor and reaction tube technology, applied in chemical instruments and methods, preparation with chloride, chlorine/hydrogen chloride, etc., can solve the problem of insufficient catalyst life, and achieve the effect of stably maintaining catalytic activity and effectively utilizing catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

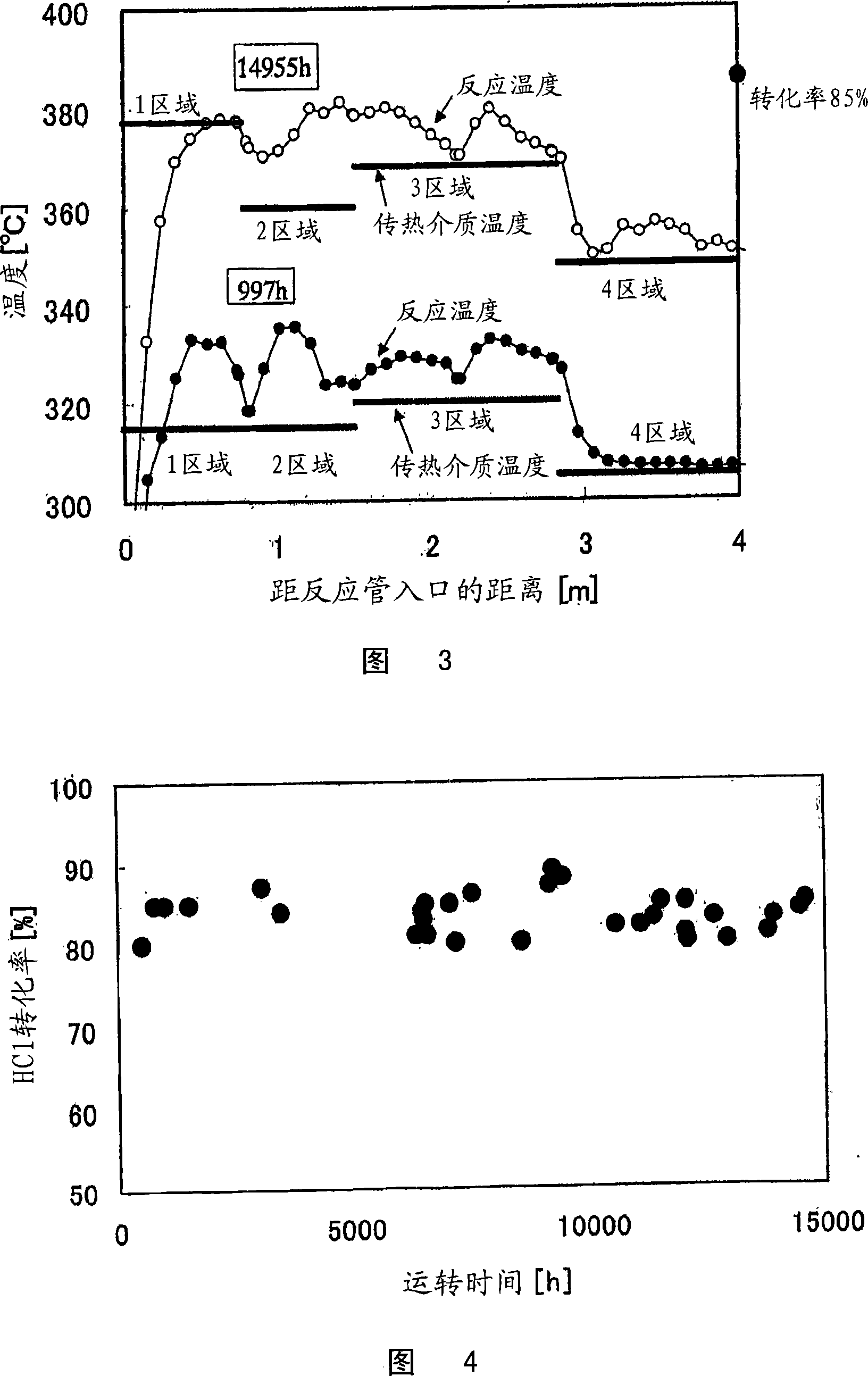

[0102] Hereinafter, the present invention will be described in more detail using examples, but the present invention is not limited by the examples.

[0103] [1] Preparation of catalyst

[0104] (1) Catalyst 1:

[0105] Titanium oxide and α-alumina were mixed in a mass ratio of 34:66 (titanium oxide:alumina), and then pure water was added and kneaded. The mixture was extruded into a cylindrical shape having a diameter of 1.5 mmφ, dried, and then crushed into a length of about 2 to 4 mm. The obtained molded product was fired at 600° C. for 3 hours in the air to obtain a support composed of a mixture of titanium oxide and α-alumina.

[0106] The carrier was impregnated with an aqueous solution of ruthenium chloride, dried, and then fired in air at 250° C. for 2 hours to obtain a supported oxide in which ruthenium oxide was supported on the carrier at a loading rate of 1% by mass. ruthenium.

[0107] (2) Catalyst 2

[0108] Titanium oxide and α-alumina were mixed in a mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com