Nitrogen-enriched doped multistage porous carbon material based on in-situ polymerization and preparation method and application thereof

An in-situ polymerization, multi-level hole technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limited application and industrial production, poor performance, high current charge and discharge, and low energy density. Huge application potential and industrial value, low cost, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

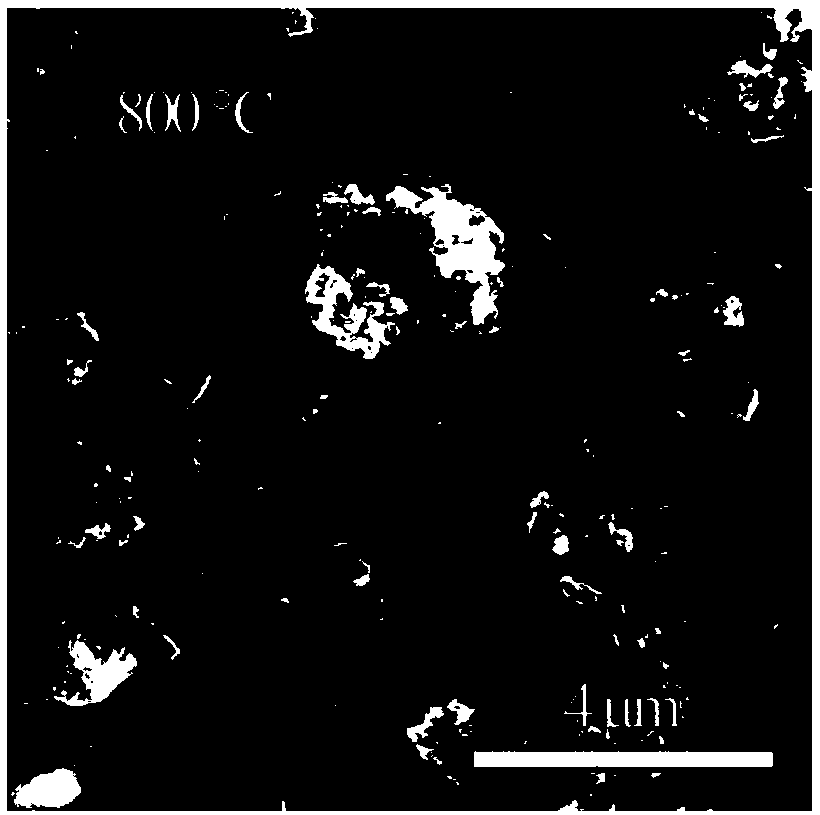

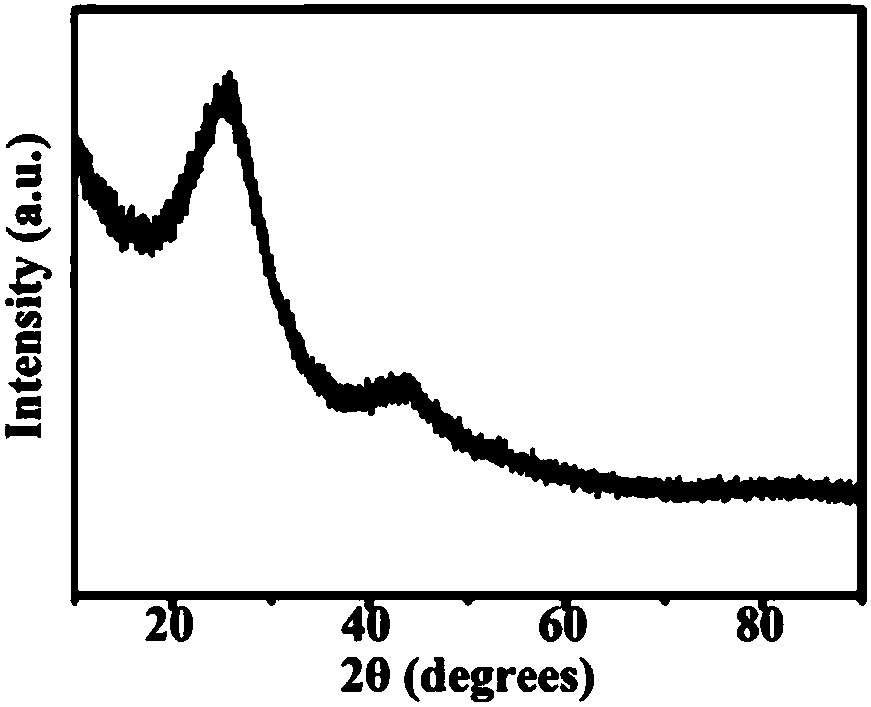

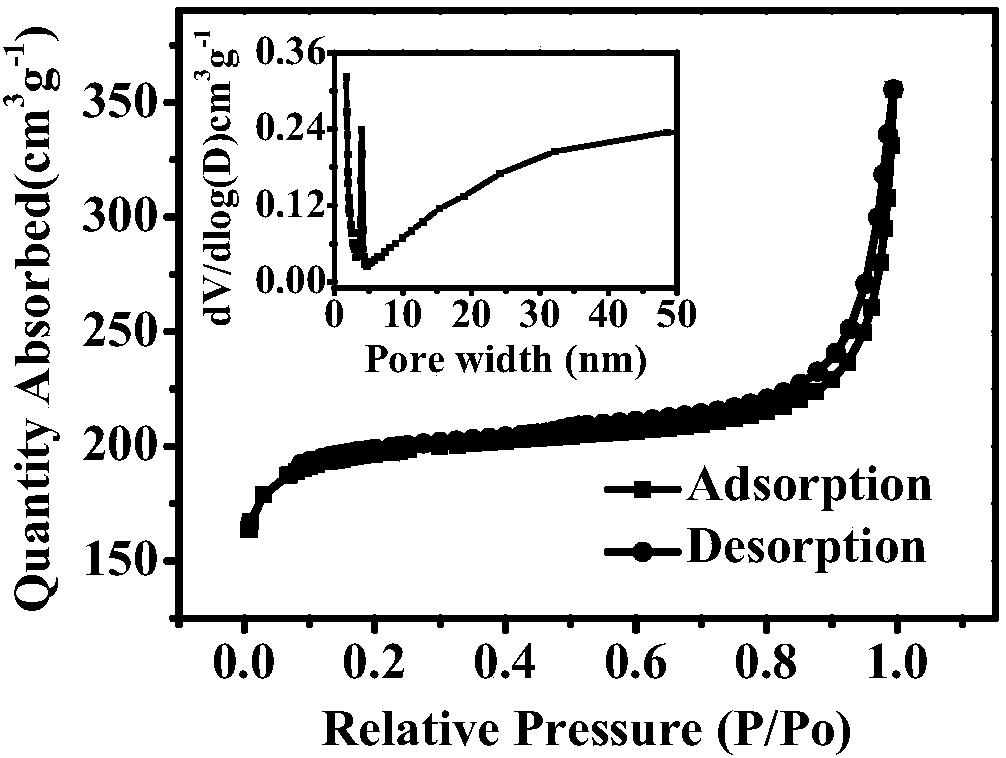

[0048] (1) Mix 4.09g of 2-methyl-5-nitroimidazole and 20mL of hexachlorobutadiene. After ultrasonication for 1h, the temperature is 200°C for 6h in a closed reaction, and then the pressure is released to normal pressure, and the dry to obtain a solid substance;

[0049] (2) Under the protection of the inert gas nitrogen, the solid material obtained in step (1) was subjected to high-temperature treatment at 800° C. for 2 hours to obtain the nitrogen-rich doped hierarchical porous carbon material based on in-situ polymerization, which was named C1.

Embodiment 2~3

[0050] Embodiment 2~3: the investigation of the temperature of reaction in the step (1)

[0051] Except that the reaction temperature in step (1) was replaced by 180° C. and 220° C., other operations remained unchanged, so that Examples 2 to 3 were carried out sequentially and named as C2 to C3 respectively.

Embodiment 4~7

[0052] Embodiment 4~7: the investigation of adding the amount of 2-methyl-5-nitroimidazole in step (1)

[0053] In addition to replacing the ratio of the amount of 2-methyl-5-nitroimidazole and hexachlorobutadiene in step (1) with 1:2, 1:3, 1:5, 1:6, other operations All remain unchanged, so that the operation of Example 1 was repeated, so that Examples 4-7 were carried out in sequence, and the obtained composite materials were named C4-C7 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com