Porous composite carbon material and application thereof

A technology of composite carbon and porous activated carbon, which is applied in the direction of nano-carbon, carbon compound, hybrid capacitor electrodes, etc., can solve the problems of short life and low power density, and achieve low internal resistance, long life of energy density, and good electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Select 50kg of porous activated carbon with a specific surface area of 2000m 2 / g, the pore size distribution is 2-5nm.

[0056] (2) Select 9.7kg of porous thin-layer graphene with a thickness of 1.2nm and a specific surface area of 1200m 2 / g.

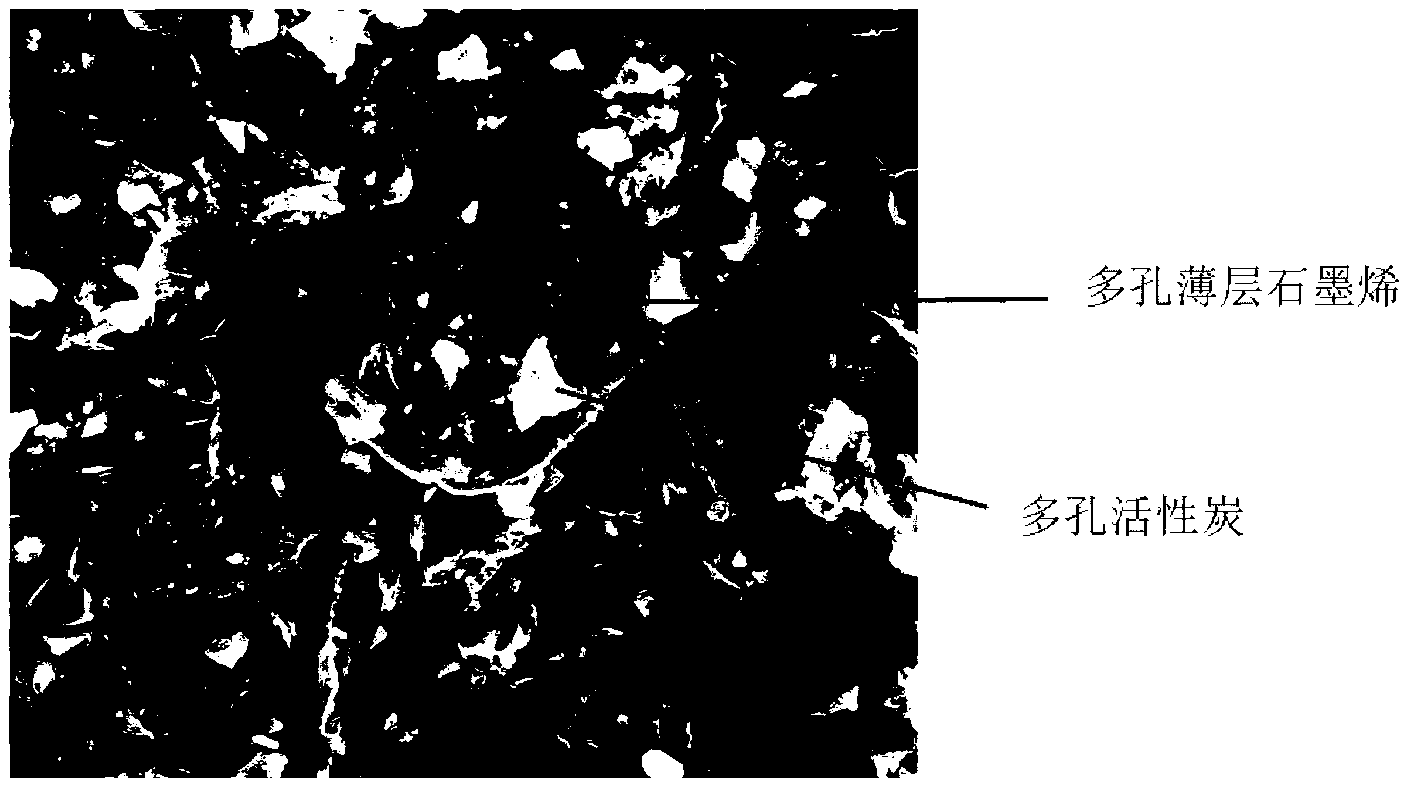

[0057] (3) Mix the aforementioned porous activated carbon and porous thin-layer graphene, add 180kg of water and 5kg of sodium carboxymethylcellulose; mechanically stir for 5 hours, and dry at 100°C for 12 hours to obtain a porous composite carbon material in a dry powder state. Such as figure 1 shown.

Embodiment 2

[0059] The porous activated carbon in Example 1 was mixed with the porous thin-layer graphene, 180 kg of water and 5 kg of sodium carboxymethyl cellulose were added; ultrasonic treatment was performed for 3 hours, and then dried at 100° C. for 12 hours to obtain a porous carbon composite material in a dry powder state.

Embodiment 3

[0061] Select the porous activated carbon in Example 1 and mix the porous thin-layer graphene, add 180kg of water and 5kg of sodium carboxymethylcellulose; mechanically stir for 5 hours, and dry at -40°C for 12 hours to obtain a porous composite carbon material in a dry powder state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com