Binary carbon material-conductive polymer composite nano gas-sensitive thin film and preparation method thereof

A technology of conductive polymers and binary carbon materials, which is applied in the field of composite nanomaterials and film technology, can solve the problems of poor selectivity and stability of single carbon material gas-sensing films, achieve excellent gas-sensing performance, and improve gas-sensing properties. Characteristics and stability, the effect of good and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

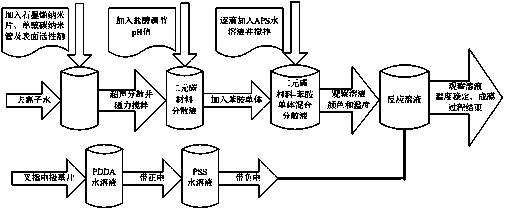

Method used

Image

Examples

Embodiment 1

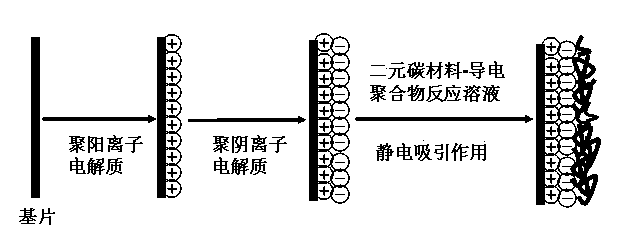

[0055] ① The gold interdigitated electrode is used as the substrate; the substrate is ultrasonically cleaned in acetone, ethanol and deionized water for 10 minutes, and dried with nitrogen;

[0056] ② Place the substrate in a volume ratio of 1:1:5 ammonia water / hydrogen peroxide / water solution for 30 minutes to make the surface of the substrate hydrophilic;

[0057] ③ Take 2ml of polydiallyl ammonium chloride (PDDA) standard solution with a concentration of 20%wt, prepare 40ml of polycationic electrolyte PDDA aqueous solution with a concentration of 1%wt, and ultrasonicate for 10min for later use; take 0.1g poly(p-styrene Sodium sulfonate) (PSS), add 47.5ml of deionized water and 2.5ml of 2mol / L hydrochloric acid solution to make polyanion electrolyte PSS aqueous solution, ultrasonic for 10min for later use;

[0058] ④ Weigh 0.5mg of graphene nanosheets and single-walled carbon nanotubes respectively, add 5ml of deionized water to prepare the aqueous dispersion of binary carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com