Tungsten trioxide powder and preparation method thereof

A technology of tungsten trioxide and powder, which is applied in the field of tungsten trioxide powder and its preparation, can solve the problems of weak photocatalytic degradation performance and gas sensing performance, achieve excellent gas sensing performance, suitable for large-scale production, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

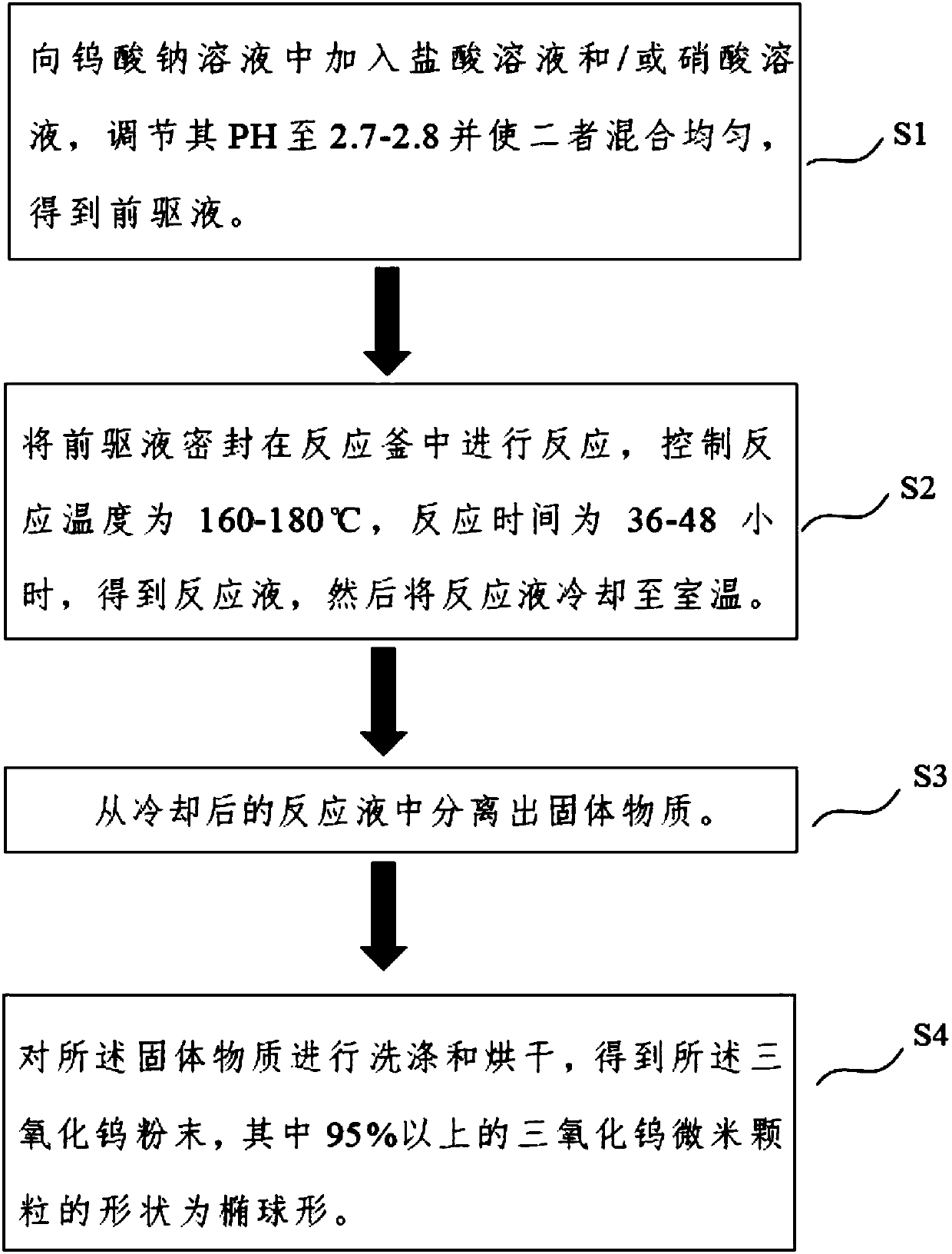

[0038] Reference figure 1 , This embodiment provides a method for preparing tungsten trioxide powder, which includes the following steps:

[0039] S1, 0.3299g sodium tungstate dihydrate (Na 2 WO 4 ·2H 2 O) Dissolve in 10 mL of distilled water to prepare a sodium tungstate solution with a concentration of 0.1 mol / L. Then add 35% by mass hydrochloric acid solution to the sodium tungstate solution with a concentration of 0.1 mol / L, adjust the pH of the sodium tungstate solution added with the hydrochloric acid solution to 2.7, and stir for 30 min after adding the hydrochloric acid solution to make the hydrochloric acid The solution and the sodium tungstate solution are evenly mixed to obtain a precursor solution. It can be understood that the precursor solution contains water, tungstate ions, sodium ions, hydrogen ions, and chloride ions at this time.

[0040] S2. Transfer the precursor liquid to the reaction kettle, and seal the precursor liquid in the reaction kettle for reaction, ...

Embodiment 2

[0060] This embodiment is based on embodiment 1, and specifically includes the following steps:

[0061] S1, add 3.2990g sodium tungstate dihydrate (Na 2 WO 4 ·2H 2 O) Dissolve in 10 mL of distilled water to prepare a sodium tungstate solution with a concentration of 1 mol / L. Then add 96% by mass nitric acid solution to the 1mol / L sodium tungstate solution, adjust the pH of the sodium tungstate solution added with nitric acid solution to 2.8, and stir for 30 minutes after adding the nitric acid solution to make the nitric acid solution Mix well with sodium tungstate solution to obtain precursor liquid. It can be understood that the precursor solution contains water, tungstate ions, sodium ions, hydrogen ions, and nitrate ions at this time.

[0062] S2. The precursor liquid is transferred to the reaction kettle, and the precursor liquid is sealed in the reaction kettle for reaction. The reaction temperature is controlled to 160°C and the reaction time is 48 hours to obtain a reacti...

Embodiment 3

[0071] This embodiment is based on embodiment 1, and specifically includes the following steps:

[0072] S1, add 3.2990g sodium tungstate dihydrate (Na 2 WO 4 ·2H 2 O) Dissolve in 20 mL of distilled water to prepare a sodium tungstate solution with a concentration of 0.5 mol / L. Then add 35% by mass hydrochloric acid solution and 98% by mass nitric acid solution to the sodium tungstate solution with a concentration of 0.5 mol / L, and adjust the pH of the sodium tungstate solution with hydrochloric acid solution and nitric acid solution to 2.75, and add the hydrochloric acid solution and stir for 30 minutes to mix the hydrochloric acid solution, nitric acid solution and sodium tungstate solution uniformly to obtain the precursor solution.

[0073] S2. Transfer the precursor liquid to the reaction kettle, and seal the precursor liquid in the reaction kettle for reaction. Control the reaction temperature to 170°C and the reaction time to 42 hours to obtain the reaction solution, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com