Synthetic method for zinc oxide nano-particles

A technology of zinc oxide nanometer and synthesis method, applied in the field of nanomaterial synthesis, can solve the problems of difficulty in meeting industrial production, unfavorable industrial production, long preparation time, etc., and achieves the effects of low device requirements, simple operation and rapid reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

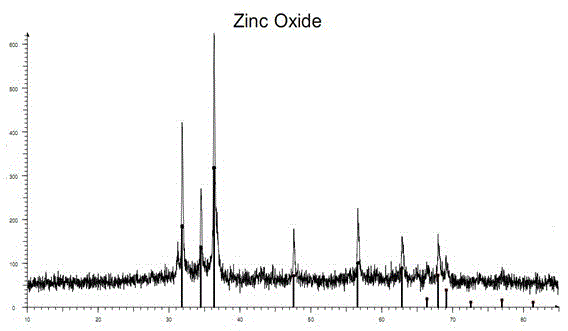

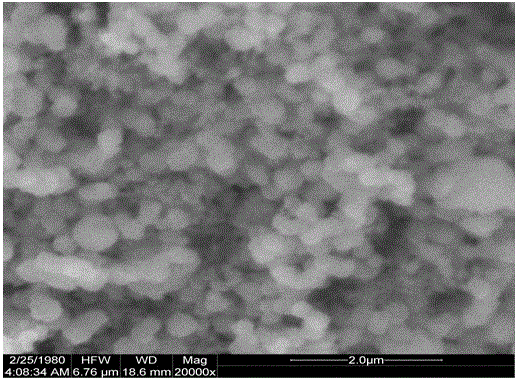

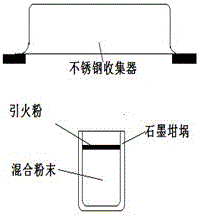

[0026] According to the mass ratio of 12.6:26.4:30.2:30.8, weigh chemically pure Al, CuO, ZnO, ZrO with a particle size of 200 mesh 2 The powder is mixed evenly and then poured into the reaction container. Spread a layer of ignition powder on the surface of the powder, and use the ignition gun to ignite the ignition powder to induce a self-propagating reaction. After the reaction is over, the product is obtained in a stainless steel collection device placed 30-40 cm above the reaction vessel, and the collected product is placed in a tube furnace for annealing at 200 degrees Celsius for fifteen minutes and slowly cooled with the furnace. The final product is tested by XRD analysis and scanning electron microscope. Tests have proved that the product is high-purity zinc oxide particles with a spherical shape and an average particle size of about 250 nanometers.

Embodiment 2

[0028] According to the mass ratio of 11.6:24.4:32.3:31.7, weigh chemically pure Al, CuO, ZnO, ZrO with a particle size of 200 mesh 2 The powder is mixed evenly and then poured into the reaction container. Spread a layer of ignition powder on the surface of the powder, and use the ignition gun to ignite the ignition powder to induce a self-propagating reaction. After the reaction is over, the product is obtained in a stainless steel collection device placed 30-40 cm above the reaction vessel, and the collected product is placed in a tube furnace for annealing at 150 degrees Celsius for ten minutes and then slowly cooled with the furnace. The final product is tested by XRD analysis and scanning electron microscope. Tests have proved that the product is high-purity zinc oxide particles with a spherical shape and an average particle size of about 230 nanometers.

Embodiment 3

[0030] According to the mass ratio of 14.2:28.3:28.2:29.3, weigh chemically pure Al, CuO, ZnO, ZrO with a particle size of 300 mesh 2 The powder is mixed evenly and then poured into the reaction container. Spread a layer of ignition powder on the surface of the powder, and use the ignition gun to ignite the ignition powder to induce a self-propagating reaction. After the reaction is finished, the product is obtained in a stainless steel collection device placed 30 to 40 centimeters above the reaction vessel, and the collected product is placed in a tube furnace for annealing at 250 degrees Celsius for 30 minutes and slowly cooled with the furnace. The final product is tested by XRD analysis and scanning electron microscope. Tests have proved that the product is high-purity zinc oxide particles with a spherical shape and an average particle size of about 270 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com