Black titanium dioxide light nano material rich in oxygen vacancy defects as well as preparation method and application thereof

A black titanium dioxide, nanomaterial technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the reaction cannot be fully carried out, pure black titanium dioxide cannot be obtained, and the carbon content and purity are not clearly given. and other problems, to achieve the effect of flexible and adjustable temperature range, low temperature requirements for preparation environment, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention discloses a method for preparing a black titanium dioxide nanomaterial rich in oxygen vacancy defects, which comprises the following steps:

[0044] Step 1: dissolving the soluble titanium salt in deionized water, fully stirring to obtain a clear solution, adjusting the pH value of the soluble titanium salt aqueous solution to weak alkalinity (pH=8-10) by adding lye dropwise at room temperature, and obtaining a precipitate, Wash the precipitate with deionized water to remove impurity ions, then add excess hydrogen peroxide solution and stir well. Under the condition of heating at 85° C., excess hydrogen peroxide solution was removed to obtain titanium sol.

[0045] Step 2: Add a reducing agent to the titanium sol, react at 20-100°C for 1-4 hours, filter and centrifuge the reduced product, put it in an oven at 40-80°C for 3-12 hours, and then grind it into powder to obtain titanium precursor gel.

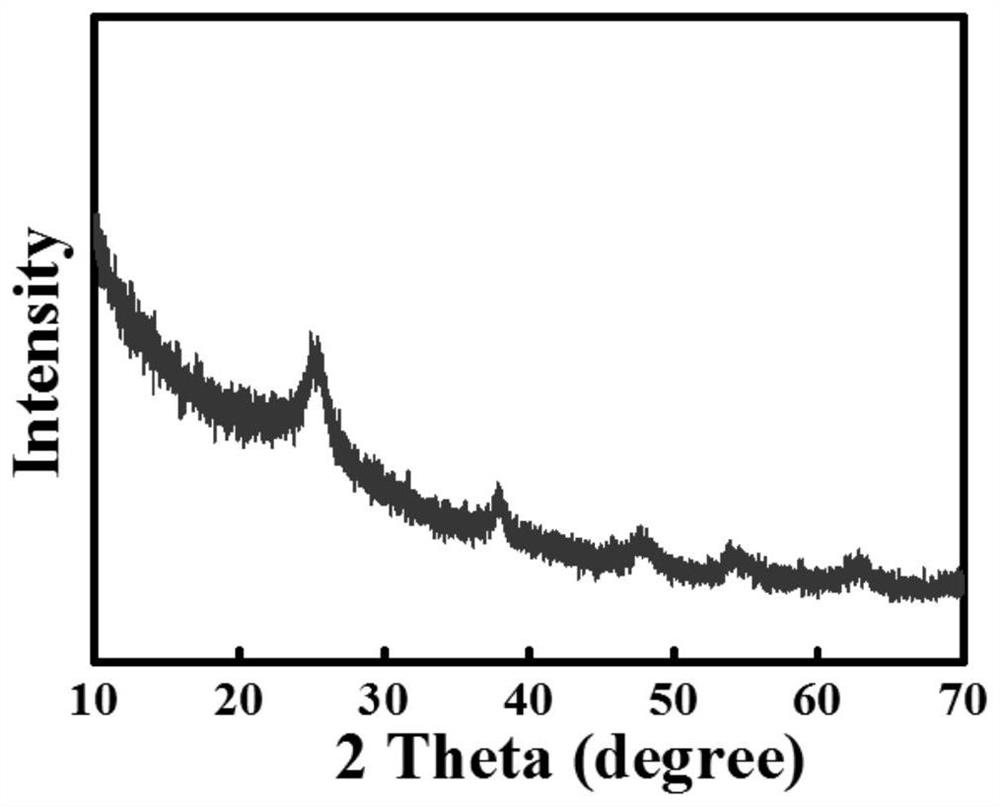

[0046] Step 3: heat-treat the titanium precursor gel cont...

Embodiment 1

[0057] Step 1. Slowly add 0.1mol titanyl sulfate to 500mL deionized water, stir at 600r / min for 4h until the solution is clear and transparent, adjust the pH of the solution to 9 with ammonia water, and obtain a precipitate, filter the precipitate, centrifuge and add 50mL of mass The fraction is 30% hydrogen peroxide aqueous solution, after stirring for 30 minutes, the solution is heated to 85° C., and heated for 10 minutes to remove excess hydrogen peroxide. Cool to room temperature to obtain titanium sol.

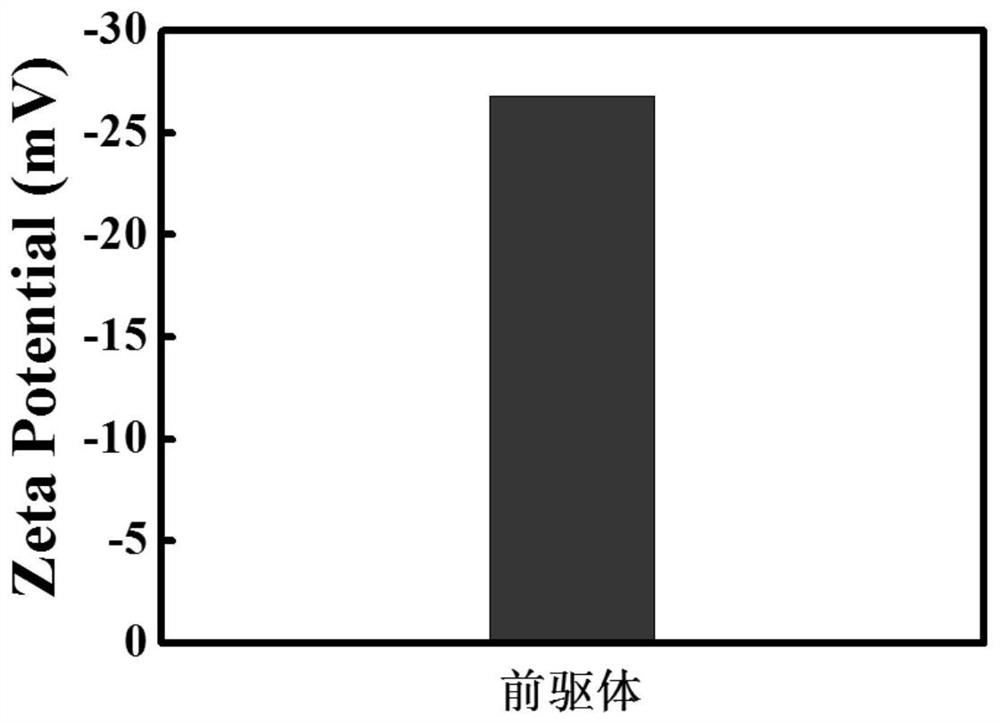

[0058] Step 2. Add hydroxylamine hydrochloride to the titanium sol. The molar ratio of hydroxylamine hydrochloride to titanium is 2:1, the reduction temperature is 30°C, and the time is 1h. The zeta potential of the titanium precursor gel containing charged groups is -26.8mV.

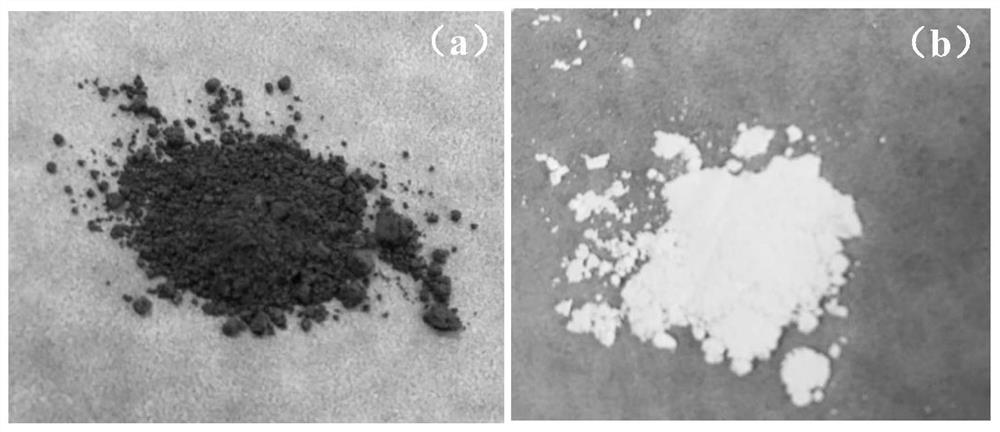

[0059] Step 3. Put the titanium precursor gel containing charged groups into a drying oven at a drying temperature of 40° C. for 3 hours to obtain solid particles, which are fully ground into powde...

Embodiment 2

[0062] Step 1. Slowly add 37.94g of titanium tetrachloride (0.2moL) to 1000mL of deionized water, stir at 800r / min for 2h, until the solution is clear and transparent, adjust the pH of the solution to 9 with ammonia water, and obtain a precipitate, filter the precipitate, After centrifugation, add 200 mL of 30% hydrogen peroxide aqueous solution, stir for 1 hour, then heat the solution to 85°C for 20 minutes to remove excess hydrogen peroxide. Cool to room temperature to obtain titanium sol.

[0063] Step 2. Add hydrazine hydrate to the titanium sol, the molar ratio of hydrazine hydrate to titanium is 2.5:1, the reduction temperature is 50°C, and the time is 1h, to obtain a titanium precursor gel containing a charged group of +10.36mV.

[0064] Step 3. Put the titanium precursor gel containing charged groups into a drying oven at a drying temperature of 60° C. for 3 hours to obtain solid particles, which are fully ground into powder.

[0065] Step 4. Under an argon protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com