Carbon-based-multimetal composite nanometer catalytic material as well as preparation method and application thereof

A nano-catalytic material and multi-metal oxide technology, which is applied in the preparation of amino compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of complex components, harm to human health and environmental safety, Solve problems such as high salt content, achieve uniform distribution of metal particles, broad market application prospects, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

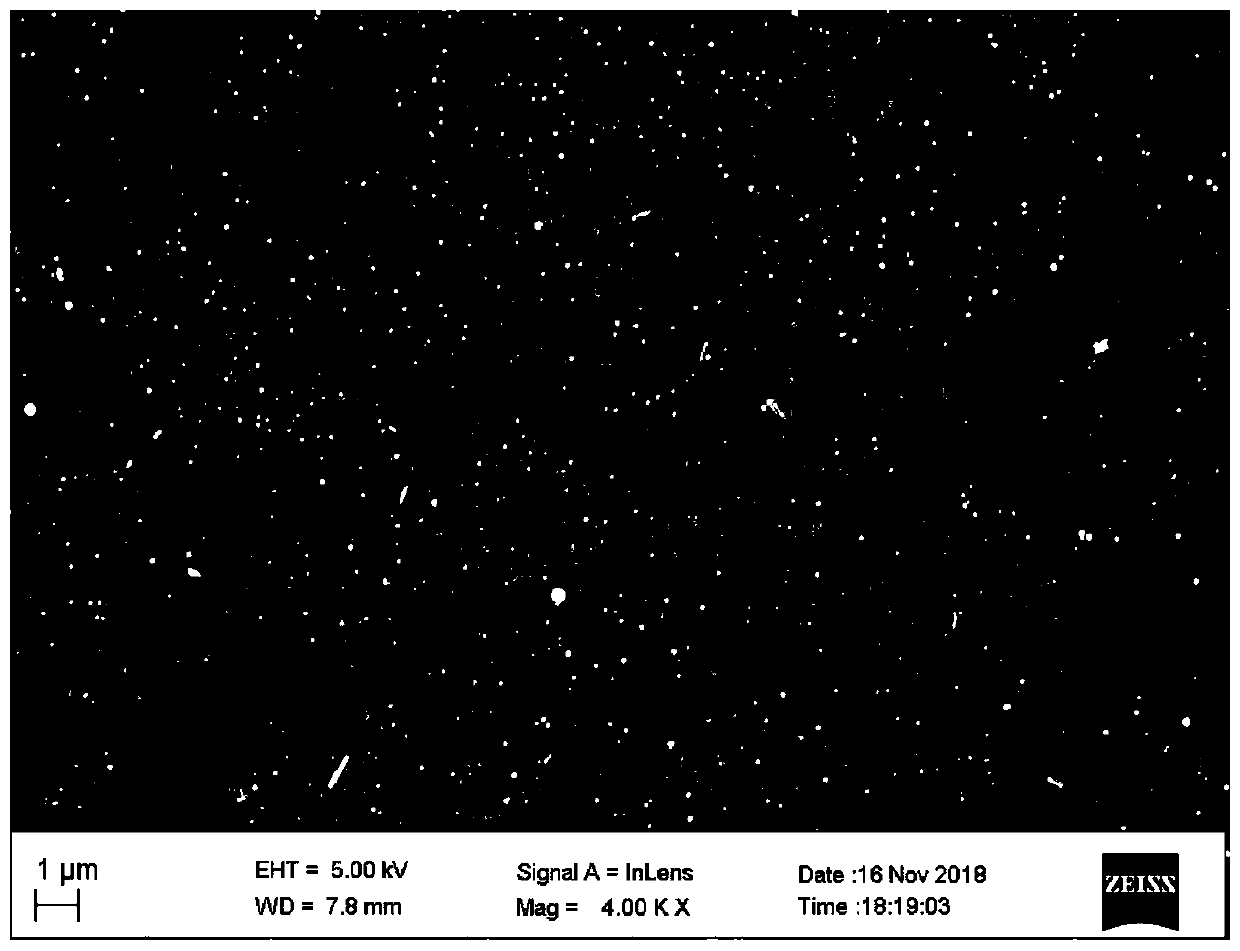

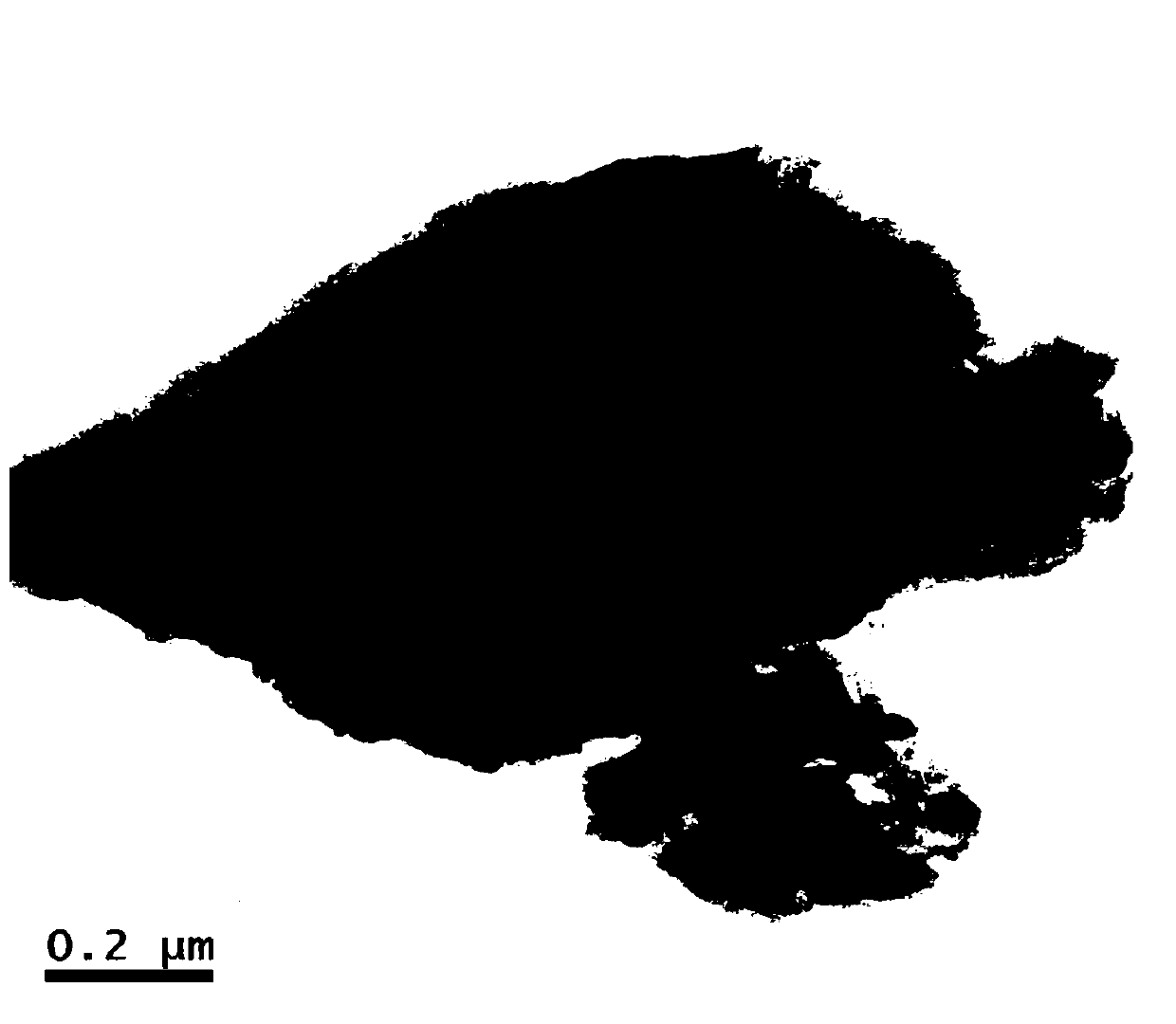

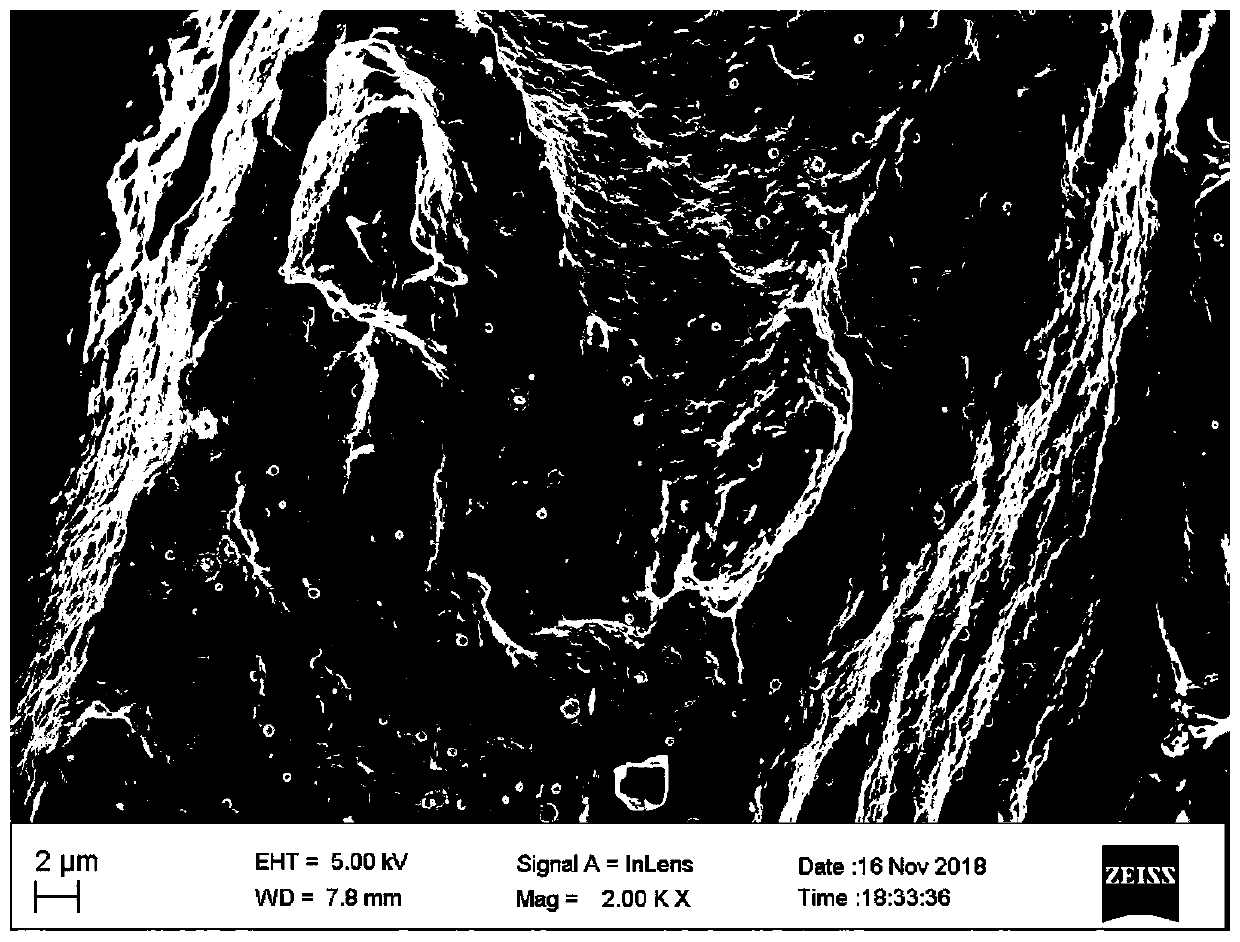

[0046] A carbon-based-polymetallic nano-catalytic material of the present invention is based on the carbon-based material containing micropores obtained by living Escherichia coli (Escherichia coliBL21) after carbonization and activation, and is loaded on the surface of the carbon-based material and in the micropores. Cu, CuO, Cu 2 O, Fe, FeO, Fe 2 o 3 , Fe 3 o 4 , Mn, MnO, MnO 2 , Mn 2 o 3 , Mn 3 o 4 , Al, Al 2 o 3 The nano-particles of multi-metal simple substance and multi-metal oxide, the carbon-based-multi-metal composite nano-catalyst material is irregular sheet-like nano-carbon, and its average size is 80×300nm; the average particle size of multi-metal oxide nanoparticles is 33.4nm.

[0047] The preparation method of carbon-based-multimetal nanocatalytic material in the present embodiment comprises the following steps:

[0048] 1) Escherichia coli (Escherichia coli BL21) was inoculated and expanded into 1 L of LB medium under sterile conditions, and after sh...

Embodiment 2

[0057] A carbon-based multi-metallic nano-catalytic material of the present invention is based on a carbon-based material containing micropores obtained after carbonization and activation of living Shewanella (Shewanellaoneidensis MR-1), on the surface of the carbon-based material and micro Loaded with Pt, PtO in the hole 2 , PtO, Pd, PdO and other multi-metal simple substances and multi-metal oxide nanoparticles, carbon-multi-metal composite nano-catalytic materials are irregular sheet-like nano-carbons, and their average size is 80×300nm; nano-particles of multi-metal oxides The average particle diameter of the particles was 32.6 nm.

[0058] The preparation method of carbon-based-multimetal nanocatalytic material in the present embodiment comprises the following steps:

[0059] 1) Under sterile conditions, inoculate and expand Shewanella oneidensis MR-1 into 1L of LB medium, shake culture at 30°C for 36h to reach the logarithmic phase, and then centrifuge at 8000rpm for 20...

Embodiment 3

[0068] A carbon-based multi-metallic nano-catalytic material of the present invention is based on a carbon-based material containing micropores obtained after carbonization and activation of living Shewanella (Shewanellaoneidensis MR-1), on the surface of the carbon-based material and micro The holes are loaded with Ti, TiO, TiO 2 、Ti 3 o 5 , W, WO 2 、WO 3 The nano-particles of multi-metal simple substance and multi-metal oxide, the carbon-based-multi-metal composite nano-catalytic material is irregular sheet-like nano-carbon, and its particle size is an average size of 80×300nm; the average size of multi-metal oxide nanoparticles is The particle size is 33.5 nm.

[0069]The preparation method of carbon-based-multimetal nanocatalytic material in the present embodiment comprises the following steps:

[0070] 1) Under sterile conditions, inoculate and expand Shewanella oneidensis MR-1 into 1L of LB medium, shake culture at 25°C for 12 hours to reach the logarithmic phase, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com