Preparation method of zinc ferrite/tin dioxide composite nano material with good gas-sensitive response to acetone gas

A technology of composite nanomaterials and tin dioxide, which is applied in the field of gas-sensing sensing materials, can solve problems such as damage to the central nervous system, and achieve the effects of lowering working temperature, good gas-sensing performance, and improving the degree of gas-sensing response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Weigh 6.010g of zinc nitrate hexahydrate and 16.490g of iron nitrate nonahydrate, and dissolve them in deionized water in turn to form A solution;

[0045] (2) Weigh 13.902g of anhydrous citric acid and fully dissolve it in solution A;

[0046] (3) Constantly stir and sonicate solution A for 30 minutes, and add 2 g of polyethylene glycol (PEG);

[0047] (4) At the same time, use ammonia water to adjust the pH of the solution to 7, place it in an 80°C water bath and stir, stop stirring after 6-8 hours to form a gel, and continue heating for 48 hours;

[0048] (5) Pass the obtained xerogel through an electric furnace at a temperature of 500°C to fully remove organic matter to obtain ZFO precursor powder;

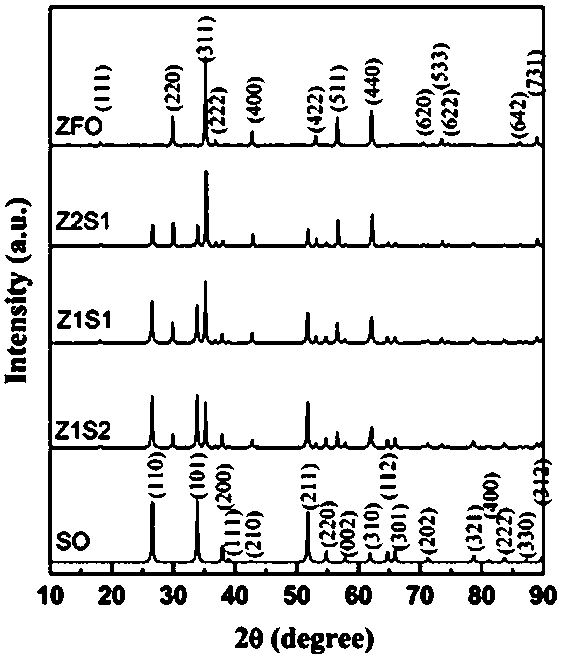

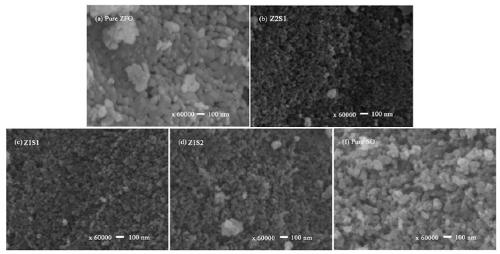

[0049] (6) The obtained ZFO precursor powder is fully ground and placed in a muffle furnace, heated to 600°C at a rate of 10°C / min for calcination for 2 hours, and then annealed at a rate of 10°C / min to 200°C to form ZFO nanopowder sample, figure 1 It shows that ...

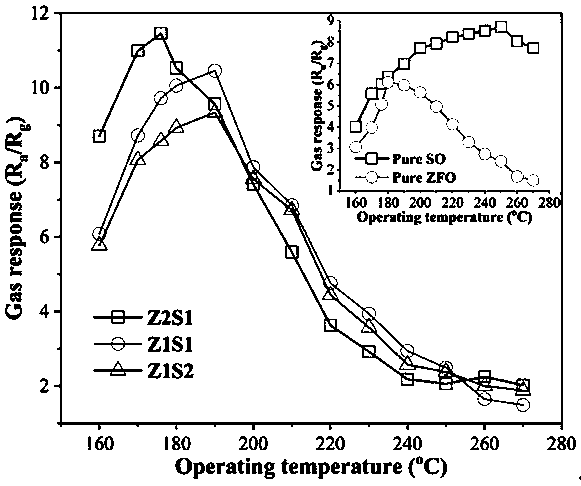

Embodiment 2

[0062] The difference between this example and Example 1 is that the composite molar ratio of zinc ferrite to tin dioxide is different (ZFO / SO=1:1). The gas sensitivity test found that compared with Example 1, the best response value of the sample to 100ppm acetone gas was 9.72, and the best working temperature was increased.

Embodiment 3

[0064] The difference between this example and Example 1 is that the composite molar ratio of zinc ferrite to tin dioxide is different (ZFO / SO=1:2). After the gas sensitivity test, it is found that compared with Example 1, the gas sensitivity performance of the sample is reduced, and the best response value for 100ppm acetone gas is 8.58.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com