Formaldehyde gas sensitive material based on tin sludge recovery treatment, and preparation method thereof

A technology of formaldehyde gas and tin sludge, which is applied in the analysis of materials, material resistance, and material analysis through electromagnetic means, to achieve the effects of resource saving, production cost reduction, high sensitivity and response recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

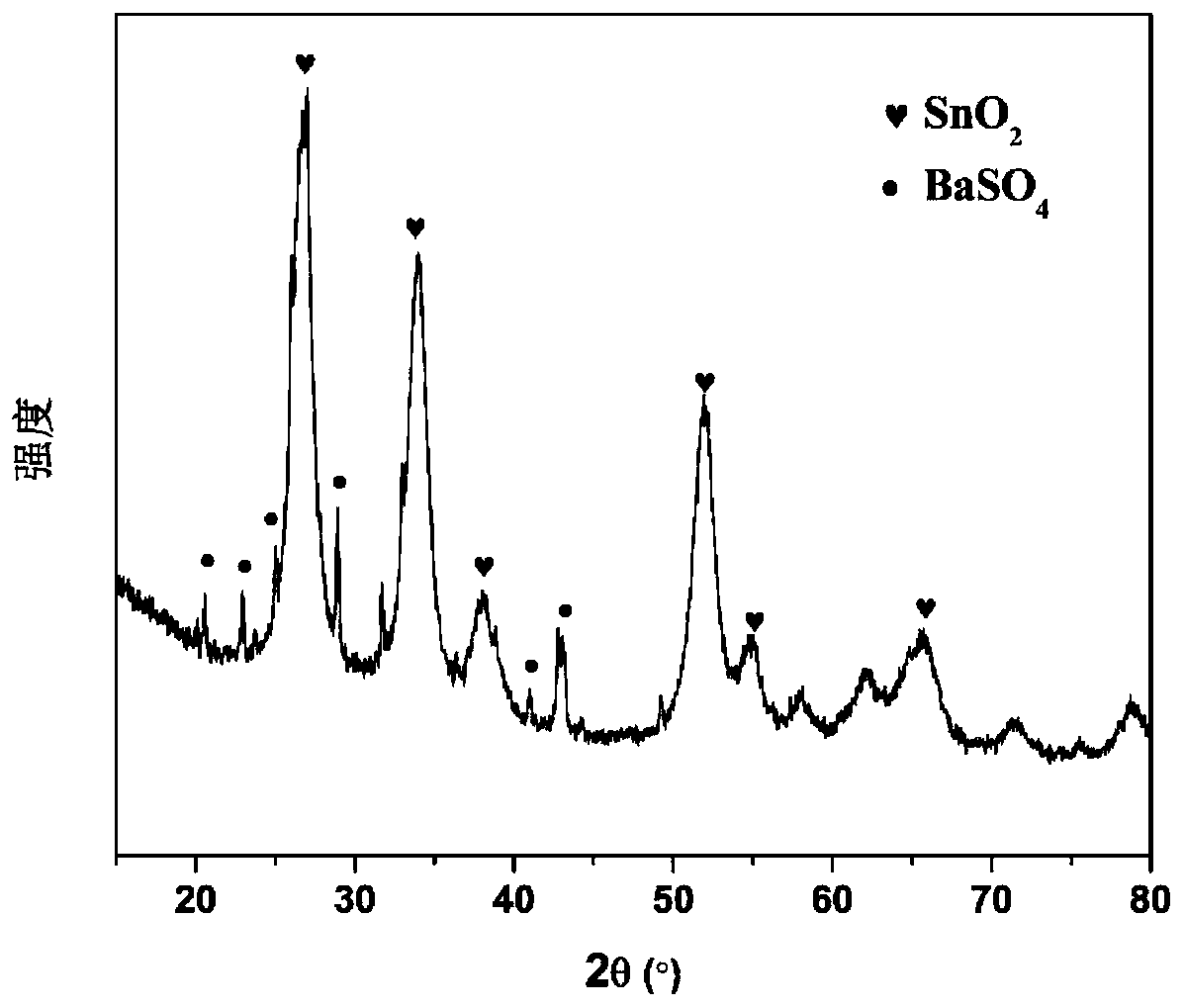

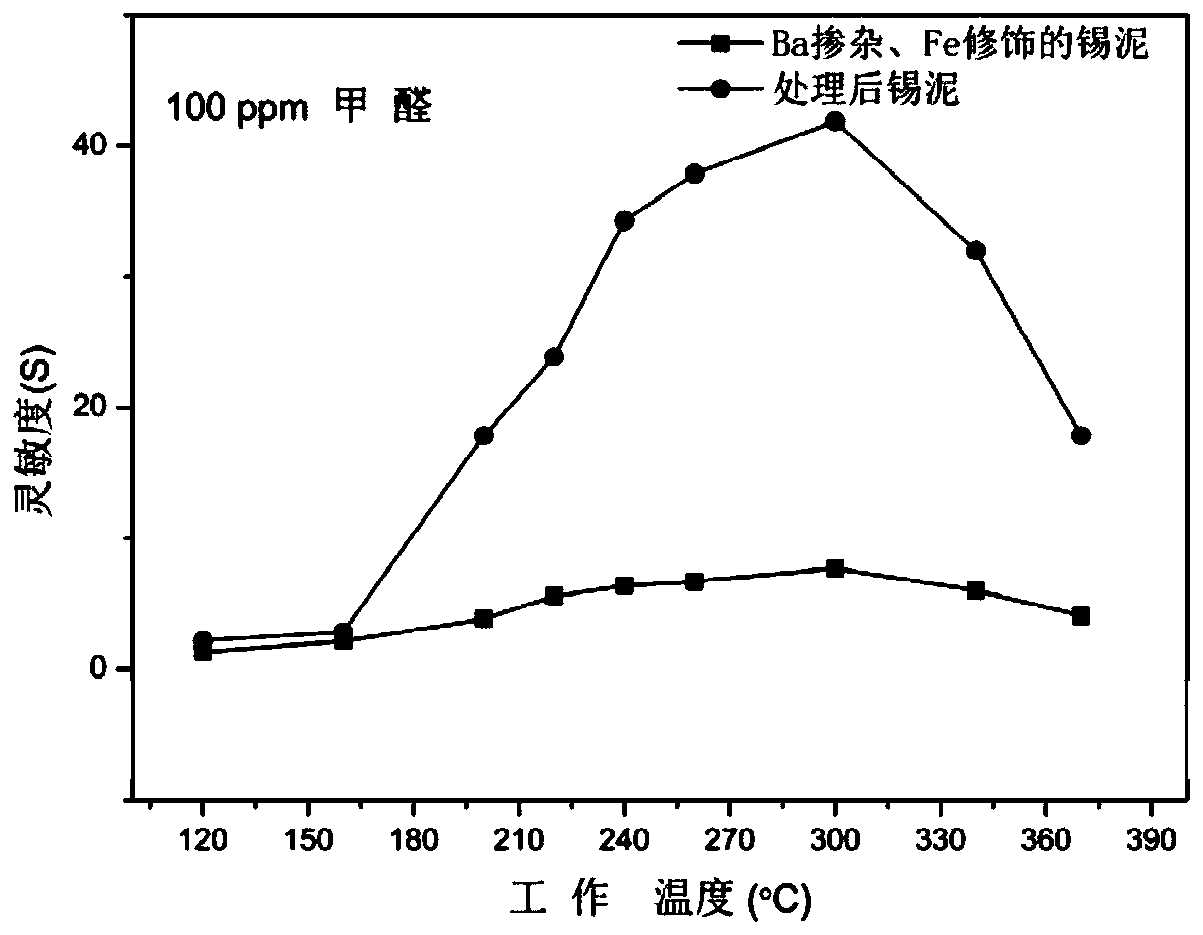

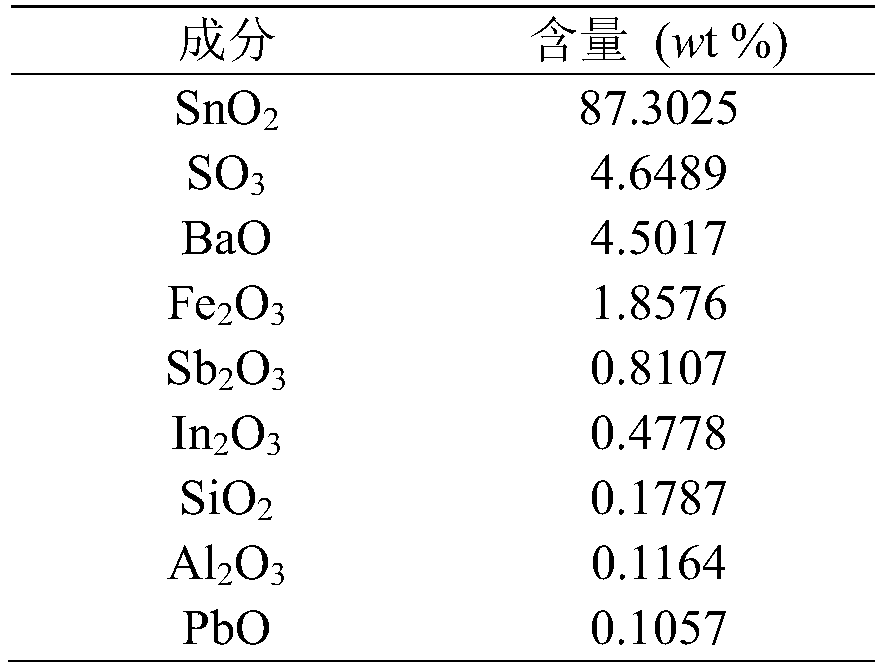

[0038] Take 5g of recovered tin mud and dissolve it in 30ml of deionized water, stir vigorously at 2000rpm for 30min, and then separate the solid and liquid through suction filtration. To achieve solid-liquid separation, dissolve the obtained filter residue in 50ml deionized water, add 3.5ml0.5mol / L Ba(OH) to it under magnetic stirring 2The prepared solution and 10ml of 0.5mol / L dilute sulfuric acid solution were magnetically stirred at room temperature for 1 hour, and then the obtained solution was centrifuged to achieve solid-liquid separation. After heat preservation at 60°C in a drying oven for 12 hours, grind the dried solid into a uniform powder and place it in a muffle furnace at a heating rate of 5°C / min at 500°C for 2 hours. After the reaction is completed, cool it down to room temperature in the furnace Get BaSO 4 Doped Recycled Slime. Weigh 3g BaSO 4 The reclaimed tin sludge of doping is placed in the agate ball mill tank, and Fe is added thereto according to the...

Embodiment 2

[0046] Take 5g of recovered tin mud and dissolve it in 30ml of deionized water, stir vigorously at 2000rpm for 30min, and then separate the solid and liquid through suction filtration. Realize solid-liquid separation, the obtained filter residue is dissolved in 50ml deionized water, and 5ml0.5mol / L Ba(OH) is added thereto under magnetic stirring 2 The prepared solution and 7.5ml 0.5mol / L dilute sulfuric acid solution were magnetically stirred at room temperature for 1 hour, and then the obtained solution was centrifuged to achieve solid-liquid separation. Place it in a drying oven at 60°C for 12 hours, grind the dried solid into a uniform powder and place it in a muffle furnace at 400°C for 2 hours at a heating rate of 5°C / min. After the reaction is completed, cool it down to room temperature in the furnace After getting BaSO 4 Doped Recycled Slime. Weigh 3g BaSO 4 The doped reclaimed tin sludge is placed in an agate ball mill jar, and Fe is added thereto at a mass ratio of...

Embodiment 3

[0049] Take 5g of recovered tin mud and dissolve it in 30ml of deionized water, stir vigorously at 2000rpm for 30min, and then separate the solid and liquid through suction filtration. Realize solid-liquid separation, the obtained filter residue is dissolved in 50ml deionized water, and 4.5ml0.5mol / L Ba(OH) is added thereto under magnetic stirring 2 The prepared solution and 20ml of 0.5mol / L dilute sulfuric acid solution were magnetically stirred at room temperature for 1 hour, and then the obtained solution was centrifuged to achieve solid-liquid separation. After heat preservation at 60°C in a drying oven for 12 hours, grind the dried solid into a uniform powder and place it in a muffle furnace at a heating rate of 5°C / min at 600°C for 2 hours. After the reaction is completed, cool it down to room temperature in the furnace Get BaSO 4 Doped Recycled Slime. Weigh 3g BaSO 4 The reclaimed tin sludge of doping is placed in the agate ball mill tank, and Fe is added thereto acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com