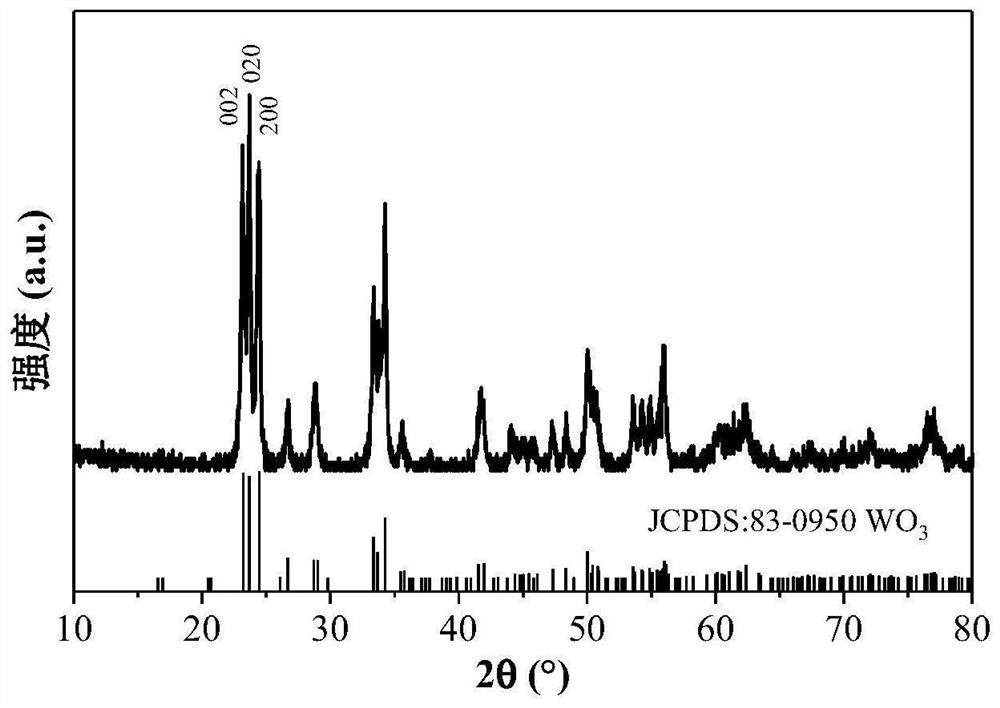

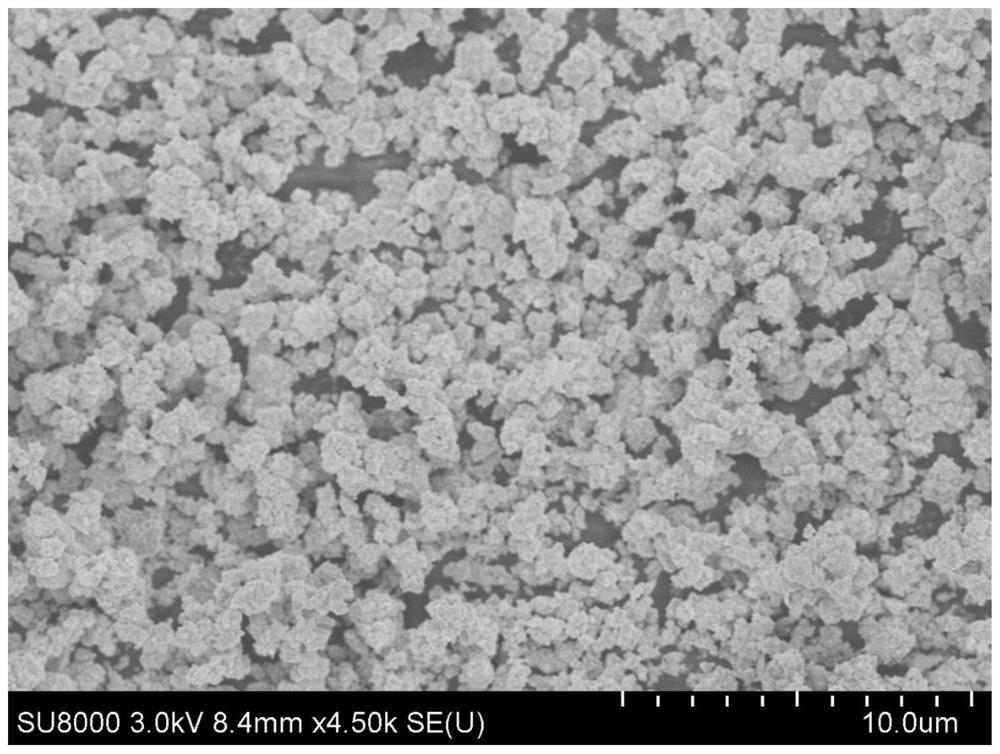

Preparation methods of spheroidic tungsten trioxide sensitive material and sulfur dioxide gas sensor and evaluation method

A gas sensor, tungsten trioxide technology, used in material resistance, material analysis, material analysis using radiation diffraction, etc., can solve problems such as endangering the personal safety of operation and maintenance personnel, reducing equipment insulation performance, discharge and overheating, etc., to achieve excellent The effect of gas-sensing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the quasi-spherical tungsten trioxide sensitive material provided by the present invention is now described. The preparation method of the spherical tungsten trioxide sensitive material includes:

[0056] Step 1, put tungsten hexachloride into a container, add absolute ethanol, and stir to form a solution;

[0057] Step 2, adding diammonium hydrogen citrate into the solution, stirring to form a suspension;

[0058] Step 3, moving the suspension into a high-pressure reactor, heating for a certain period of time, and cooling naturally to obtain a product precursor;

[0059] Step 4, collecting the product precursor, and washing with deionized water and absolute ethanol respectively;

[0060] Step 5, vacuum drying the product precursor after washing;

[0061] The dried product precursor is heated and sintered in a muffle furnace to obtain a spherical tungsten trioxide sensitive material.

[0062] The preparation method of the spherical tungsten...

Embodiment 1

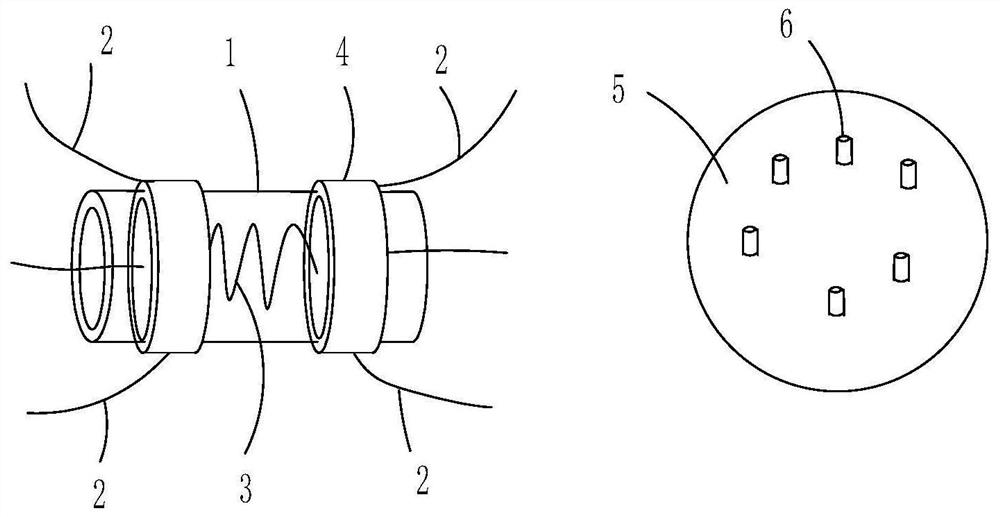

[0082] Example 1, a kind of SF based on spherical tungsten trioxide sensitive material 6 Decomposition product sulfur dioxide gas sensor, at different temperatures (20±1℃~250±2℃) for 100±1μL / L SO 2 detection of:

[0083] Step 1, turn on the precision digital multimeter, programmable DC power supply and computer. Open the software "Fluke" on the computer and set the acquisition once every 1s. Insert the manufactured sulfur dioxide gas sensor into the test socket, you can immediately see the real-time resistance of the sulfur dioxide gas sensor on the display screen of the precision digital multimeter, and you can also see the resistance change curve on the software window. Adjust the output current value of the programmable DC power supply, change the temperature of the sulfur dioxide gas sensor, and stabilize the resistance. Record the resistance R at this time a , heating current and voltage.

[0084] Step 2: Fill 10±0.1mL SO with a syringe into a 1L static gas distribut...

Embodiment 2

[0086] Embodiment 2, SF based on spherical tungsten trioxide sensitive material 6 Decomposition product sulfur dioxide gas sensor, at different temperatures (20±1℃~250±2℃), for 100μL / L SO 2 , NH 3 , ethanol, methanol, n-butanol and acetone detection:

[0087] Step 1, turn on the precision digital multimeter, programmable DC power supply and computer. Open the software "Fluke" on the computer and set the acquisition once every 1s. Insert the manufactured sulfur dioxide gas sensor into the test socket, you can immediately see the real-time resistance of the sulfur dioxide gas sensor on the display screen of the precision digital multimeter, and you can also see the resistance change curve on the software window. Adjust the output current value of the programmable DC power supply so that the heating temperature is 105±1°C. Record the resistance R at this time a , heating current and voltage.

[0088] Step 2, sequentially configure 100±1μL / L SO in a 1L static gas distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com