Nitrogen-doped mesoporous graphene microspheres, and preparation method and application thereof

A mesoporous graphene, nitrogen-doped technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of low stability, low life, high cost, etc., and achieve uniform pore size, low cost, and large pore volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

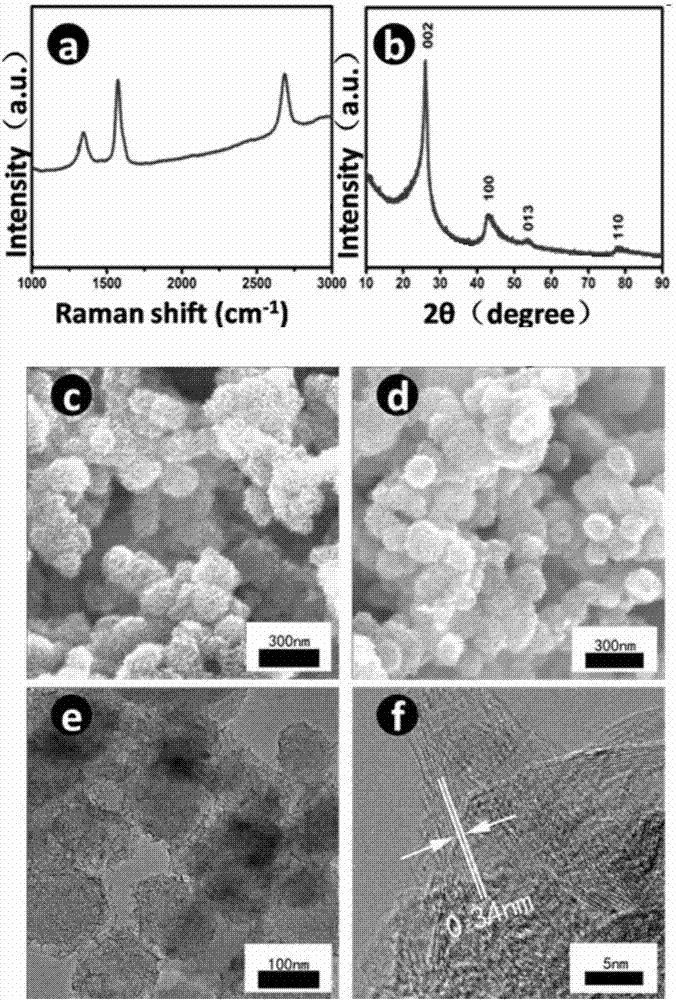

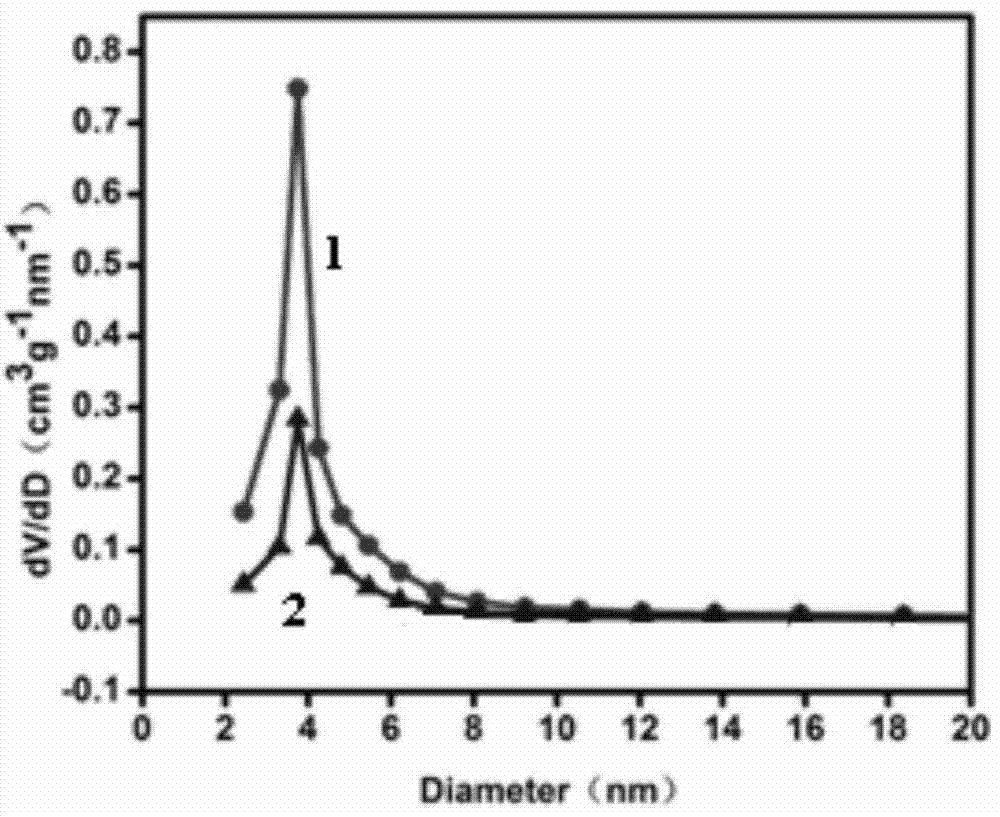

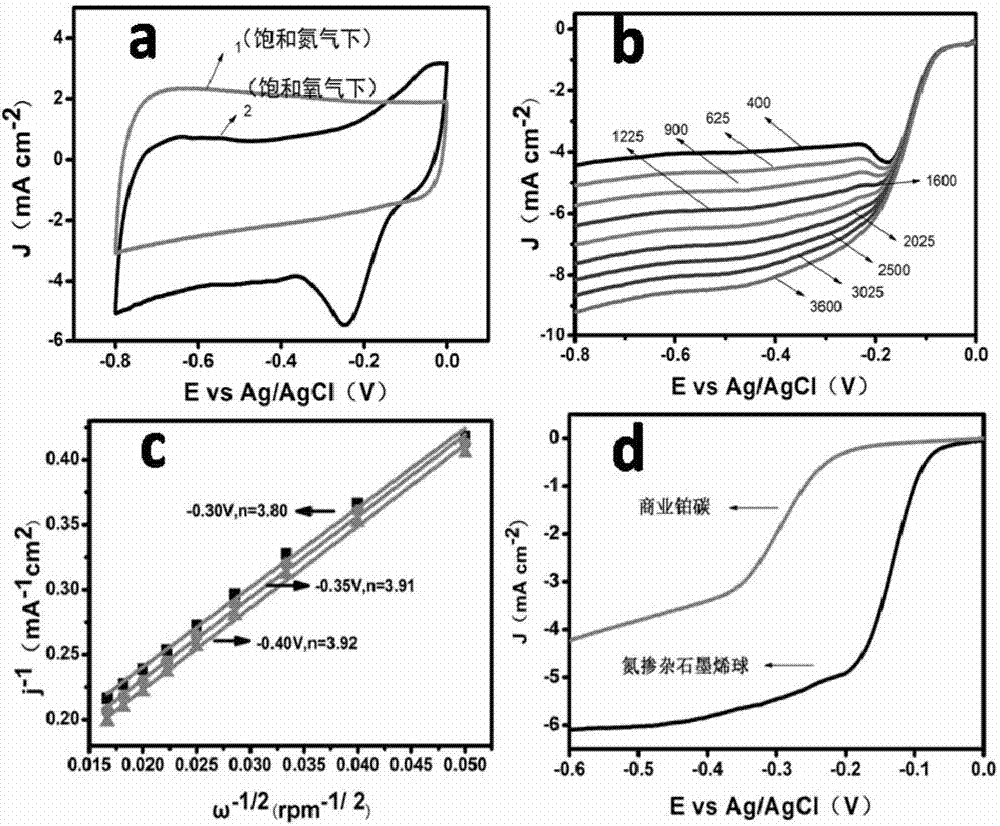

[0025] Embodiment 1 mesoporous graphene microsphere

[0026] Accurately weigh 0.2g of metal sodium block with a bright surface, pick it up with tweezers and place it in a 50ml stainless steel high-pressure reaction kettle, use a measuring cylinder to measure 40ml of hexachlorobutadiene, and slowly add it to the stainless steel reaction kettle filled with sodium block , Cover the lid of the reaction kettle, inject argon gas to 5MPa, make sure that it is tightened, and then use an electric heating jacket to raise the temperature to 240°C for 20h. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into an 8ml centrifuge tube with a straw, centrifuge at 8000r / min for 5 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add 50% ethanol aqueous solution to centrifuge, repeat 3 times, finally discard the superna...

Embodiment 2

[0027] Embodiment 2 mesoporous graphene microspheres

[0028] Accurately weigh 0.2g of metal sodium block with a bright surface, pick it up with tweezers and place it in a 50ml stainless steel high-pressure reaction kettle, measure 12ml of hexachlorobutadiene with a graduated cylinder, and slowly add it to the stainless steel reaction kettle filled with sodium block , Cover the lid of the reaction kettle, inject argon gas to 15MPa, make sure that it is tightened, and then use electric heating to raise the temperature to 200°C for 40 hours. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into an 8ml centrifuge tube with a straw, centrifuge at 8000r / min for 5 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add 50% ethanol aqueous solution to centrifuge, repeat 3 times, finally discard the supernatant ...

Embodiment 3

[0029] Embodiment 3 mesoporous graphene microspheres

[0030] Accurately weigh 0.1g of metal sodium block with a bright surface, pick it up with tweezers and place it in a 50ml stainless steel autoclave, use a graduated cylinder to measure 30ml of hexachlorobutadiene, and slowly add it to the stainless steel reaction kettle filled with sodium block , cover the lid of the reaction kettle, inject argon gas to 1MPa, make sure that it is tightened, and use electric heating to raise the temperature to 300°C for 10h. After the reaction, cool down to room temperature naturally, open the reaction kettle, collect the black product in the kettle into an 8ml centrifuge tube with a straw, centrifuge at 8000r / min for 5 minutes, absorb the upper yellow liquid, and add absolute ethanol to the centrifuge tube Centrifuge, repeat 3 times, discard the supernatant and then add 50% ethanol aqueous solution to centrifuge, repeat 3 times, finally discard the supernatant and add absolute ethanol to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com