Separation system for by-product high-boiling matter in tetrachloroethylene production and separation method

A technology for by-producing high boilers and tetrachloroethylene, applied in chemical instruments and methods, halogenated hydrocarbon disproportionation separation/purification, organic chemistry, etc., can solve the problems of complex process, inability to separate operating temperature, and high process energy consumption, Achieve the effect of reducing sublimation temperature, product sublimation temperature, and process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

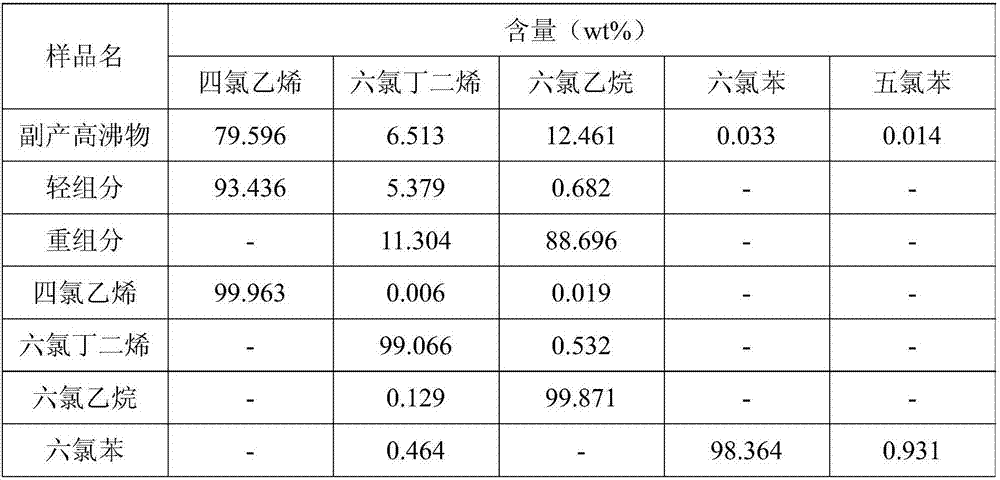

Examples

Embodiment 1

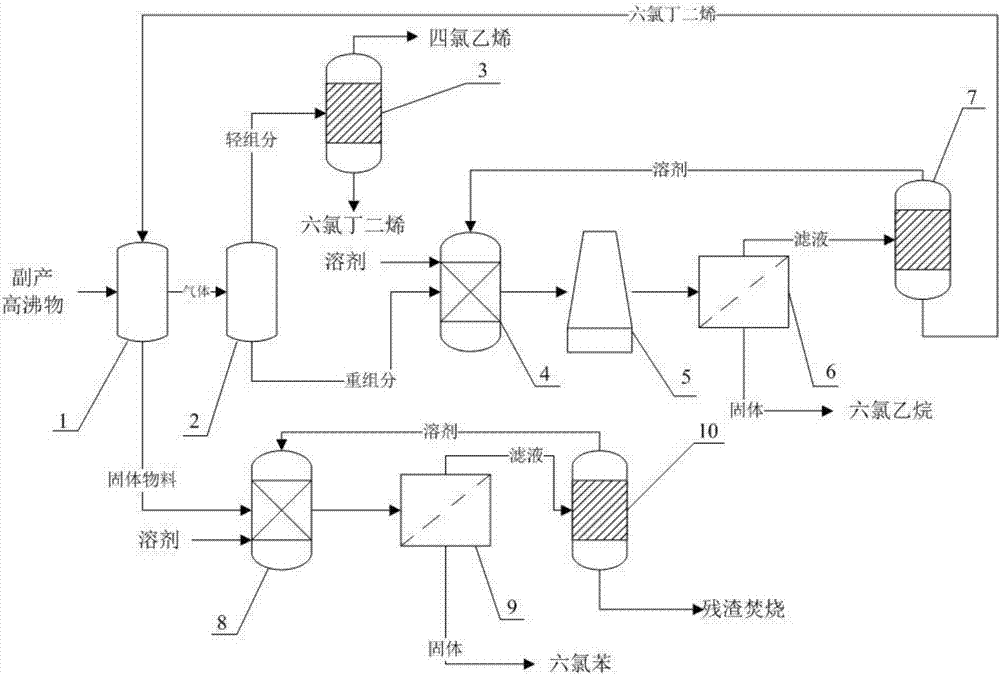

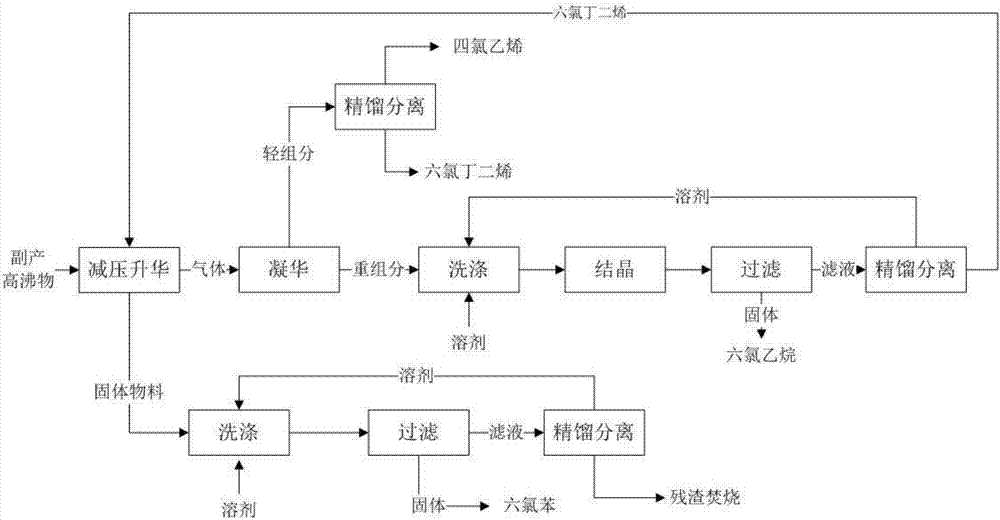

[0085] This embodiment provides a separation system for by-product high boilers in the production of tetrachlorethylene, said system comprising a decompression sublimation unit 1, a desublimation unit 2, a first rectification tower 3, a hexachloroethane separation system and Hexachlorobenzene separation system; Wherein, the gas material outlet of decompression sublimation unit 1 links to each other with desublimation unit 2 feed ports, and the light component material outlet of desublimation unit 2 links to each other with the feed port of the first rectifying tower 3, The heavy component material outlet of the desublimation device 2 is connected with the feed inlet of the hexachloroethane separation system, and the solid material outlet of the decompression sublimation device 1 is connected with the hexachlorobenzene separation system.

[0086] The hexachloroethane separation system comprises a first washing tower 4, a crystallization unit 5, a first filtering unit 6 and a sec...

Embodiment 2

[0089] This embodiment provides a separation system for by-product high boilers in the production of tetrachlorethylene. Except that the first filter device 6 is a plate and frame filter, and the second filter device 9 is a plate and frame filter, other structures are similar to those of the implementation Same as in Example 1.

Embodiment 3

[0091] This embodiment provides a separation system for by-product high boilers in the production of tetrachlorethylene, except that the first filter device 6 is a chamber filter press, and the second filter device 9 is a chamber filter press, the other structures are Same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com