High-density nitrogen-oxygen-chlorine co-doped carbon particle material as well as preparation method and application thereof

A co-doping and high-density technology, applied in the preparation/purification of carbon, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problems of limited application and industrial production, raw materials are not environmentally friendly, and difficult to practical application , to achieve huge application potential and industrial value, good electrochemical performance, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] S1: Hexachlorobutadiene and aniline were reacted in a high-pressure reactor with a polytetrafluoroethylene liner at 200°C under airtight conditions for 5 hours, wherein the molar ratio of aniline to hexachlorobutadiene was 10:1;

[0056] S2: After the reaction, cool naturally to normal temperature and pressure, centrifuge and wash the obtained solid, and dry at 80°C for 6 hours to obtain a dry sample;

[0057] S3: The dry sample was calcined at a high temperature of 900°C for 2 hours under the protection of nitrogen to obtain a nitrogen-doped porous carbon material, which was named N1.

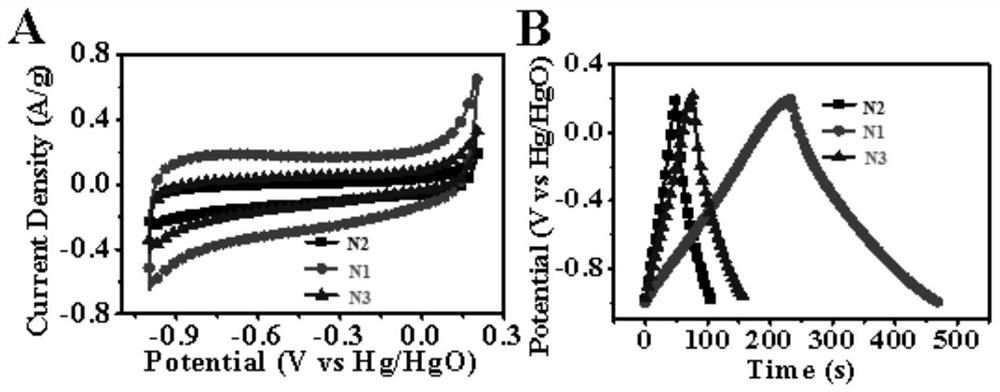

Embodiment 2-3

[0058] Embodiment 2-3: the investigation of material consumption ratio in the step S1

[0059] Embodiment 2-3: Except that in step S1, the mass ratio of aniline and hexachlorobutadiene is replaced by 5:1 and 15:1, other operations are all unchanged, thereby repeating the operation of Example 1, thereby proceeding sequentially According to Examples 2-3, the obtained carbon materials were named N2 and N3 in sequence.

Embodiment 4-5

[0060] Embodiment 4-5: the investigation of roasting temperature in the step S3

[0061] Except for replacing the high-temperature calcination temperature in step S3 from 900°C to 800°C and 1000°C, the other operations remain unchanged, so that Example 1 is repeated to obtain Examples 4-5 in sequence, and the resulting carbon material is named accordingly It is N4, N5.

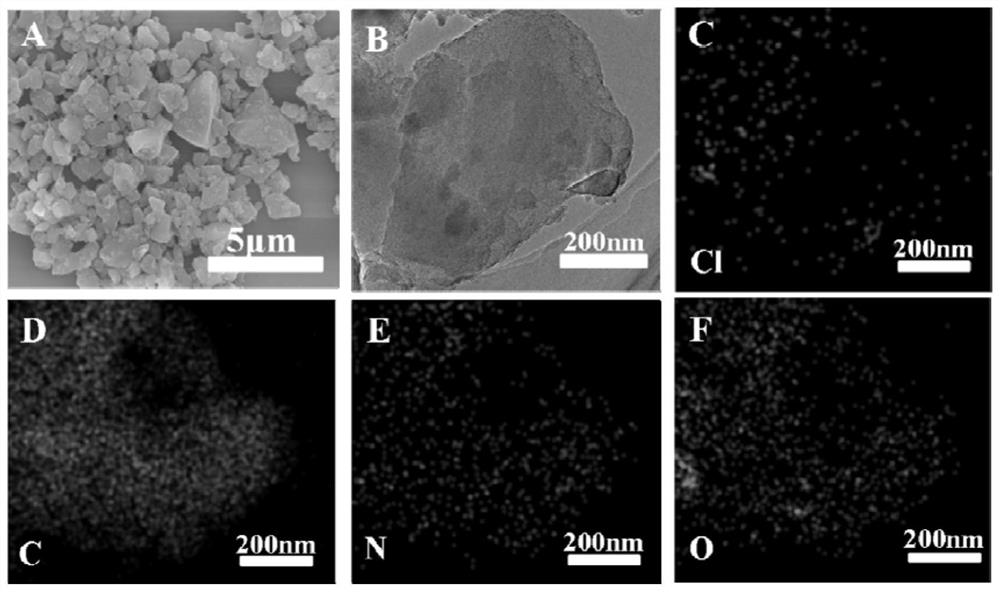

[0062] Microscopic representation

[0063] The nitrogen-doped porous carbon material N1 obtained in Example 1 was microscopically characterized by a number of different means, and the results are as follows:

[0064] 1. By figure 1 It can be seen that the N1 is composed of random carbon particles with different sizes, shapes and thicknesses, and this material has a micro-mesoporous carbon structure and an amorphous lattice. At the same time, it can be seen from the surface element distribution that four elements C, N, O, and Cl are evenly distributed on the surface of this material.

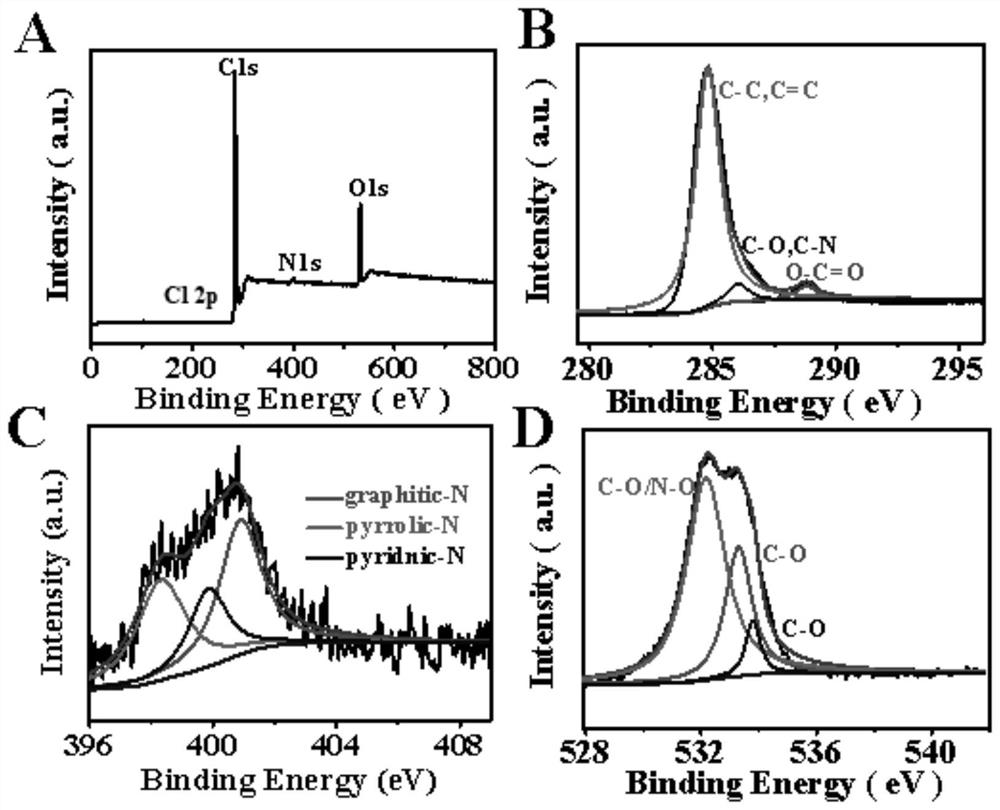

[0065] 2. By figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com