Patents

Literature

39results about How to "Many surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combination electrode hydro-thermal synthesis method for removing arsenic in water based on electro-adsorption and arsenic removing method thereof

ActiveCN103723801AImprove electrical performanceStrong oxidation abilityWater/sewage treatment by magnetic/electric fieldsGramHeavy metals

The invention provides a combination electrode hydro-thermal synthesis method for removing arsenic in water based on electro-adsorption. The combination electrode hydro-thermal synthesis method specifically comprises the following steps of: soaking active carbon fibers in dilute nitric acid or a sodium hydroxide solution for 1-24h for activation, and then washing with water; next, putting the activated active carbon fibers in a high-temperature reaction kettle, adding 2mmol of manganese salt, 0.01-0.4mmol of iron salt, 1-4mmol of K2S2O8, 2-8mL of concentrated sulfuric acid and 60-90mL of distilled water to the high-temperature reaction kettle per 1 gram, and mixing evenly; and finally, sealing the high-temperature reaction kettle, reacting at a constant temperature ranging from 90 to 150 DEG C for 2-24h, cooling to the room temperature and then washing with distilled water, and drying in an oven. The method of preparing the combination electrode provided by the invention is simple and feasible, overcomes the shortcoming that the existing drinking water trace heavy metal element treatment technology is complex and has no choice, provides excellent technical guarantee for the body health of people and has good application value.

Owner:湖南玖恪环境工程有限公司

Cobaltosic oxide catalyst, preparation method and application thereof

PendingCN110787822ARaw materials are easy to obtainLow costCatalyst activation/preparationIncinerator apparatusNitrogen plasmaPtru catalyst

The invention discloses a cobaltosic oxide catalyst, a preparation method and application thereof. The preparation method includes: (a) preparing a cobaltosic oxide nanorod Co3O4-110 with an exposed crystal surface (110); and (b) doping N atom to the surface of Co3O4-110 to obtain the cobaltosic oxide catalyst N-Co3O4-110. The preparation method of the cobaltosic oxide catalyst provided by the invention has easily controllable reaction conditions, can be operated at room temperature, and by changing the nitrogen plasma treatment time, different nitrogen doping amounts and oxygen vacancy content can be obtained. The cobaltosic oxide catalyst obtained by the preparation method disclosed by the invention has the advantages of simple and easily available raw materials, and lower cost than platinum, palladium and the like, and simple operation method, and is suitable for industrial application. The cobaltosic oxide catalyst has more surface defects, higher surface oxygen content and highercharge transfer efficiency, and can be used for catalyzing various oxidation reactions.

Owner:QINGDAO UNIV

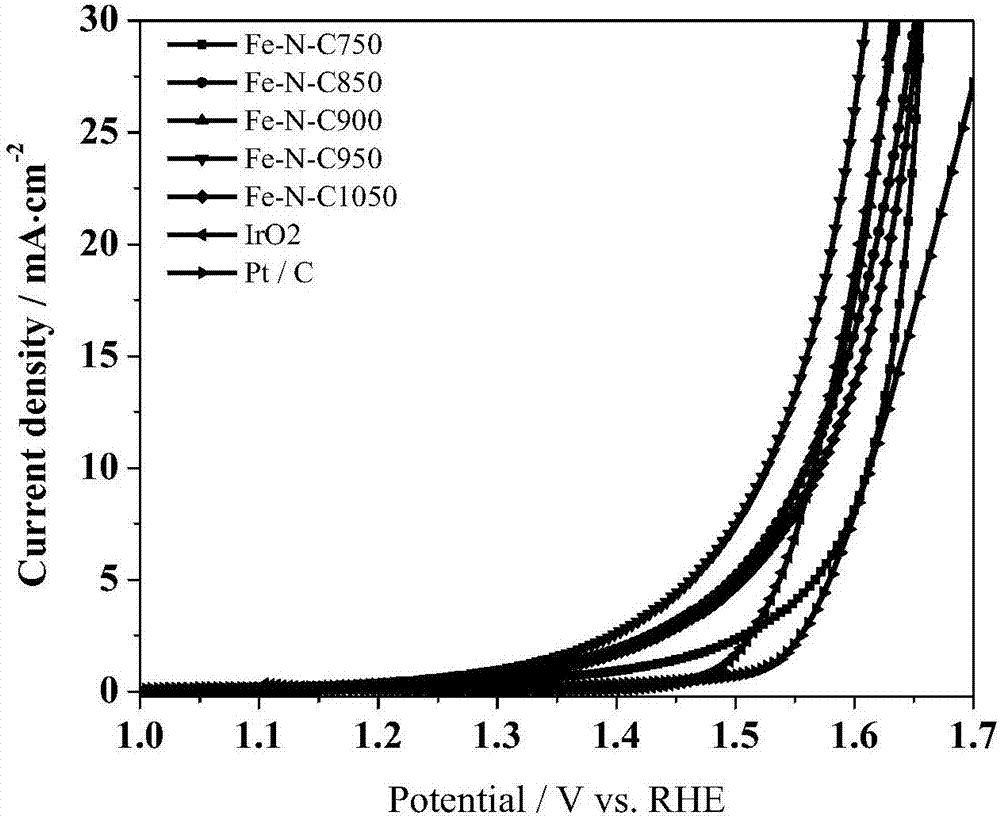

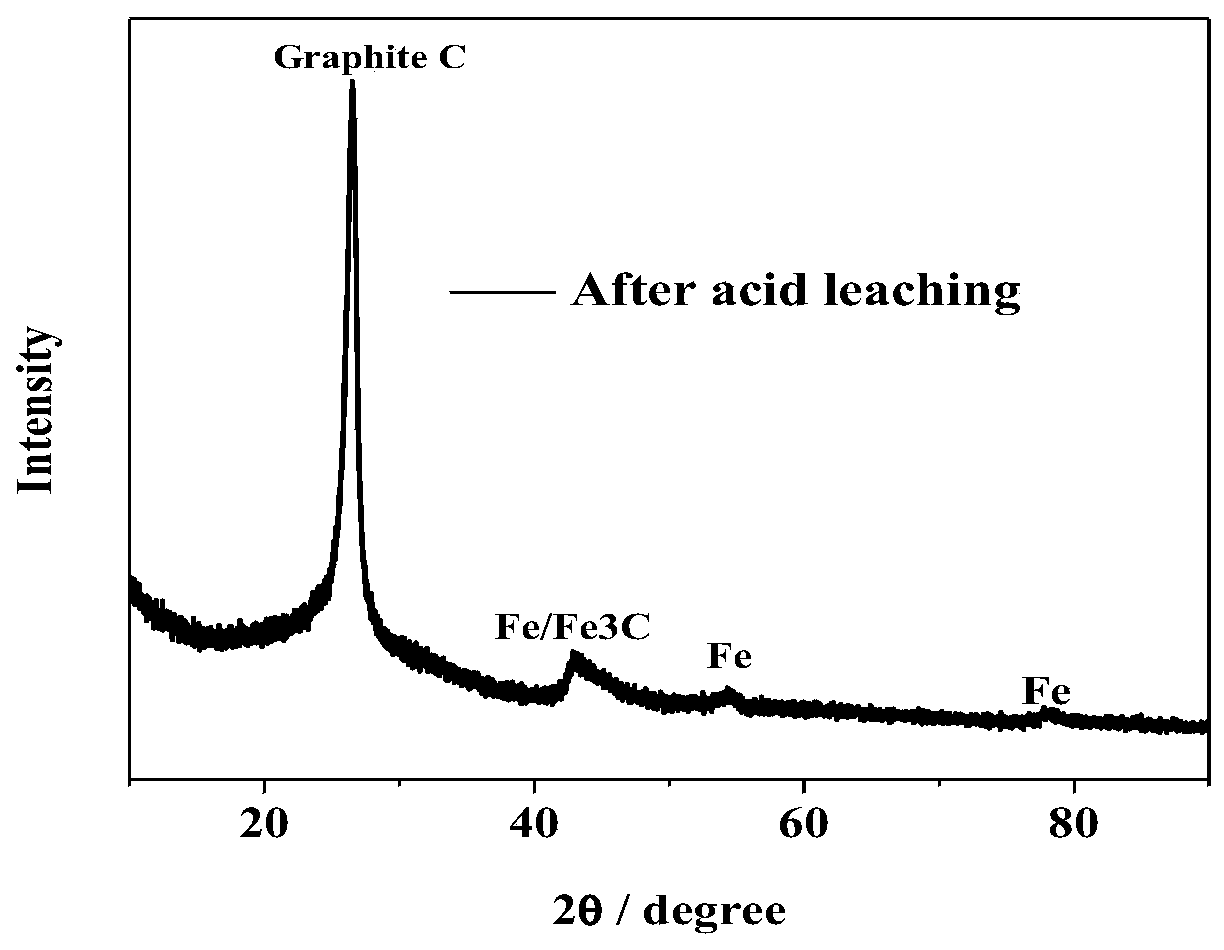

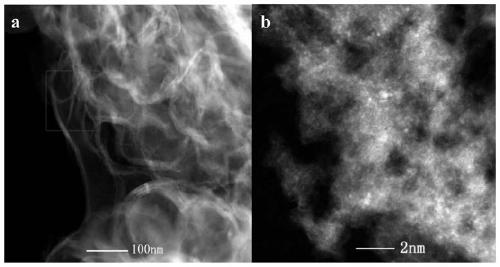

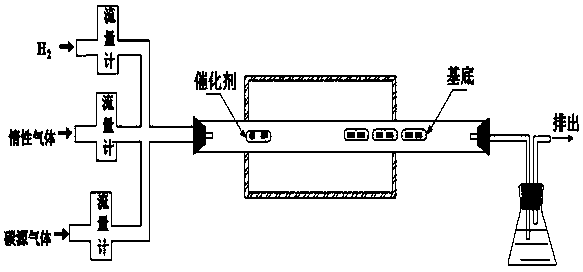

Preparation method of water electrolysis oxygen evolution non-noble metal catalyst

The invention discloses a preparation method of a water electrolysis oxygen evolution non-noble metal catalyst. The preparation method includes the steps that firstly, pyridine monomers I containing acyl or pyridine monomers I containing amidogen are added into a solvent, then monomers II containing amidogen or monomers II containing acyl and a catalyst are added in, and synthesis is performed by rising temperature; secondly, metal salt is added in, metal ions are added in for complexing, wherein according to the molar weight of the metal ions, the molar ratio of the metal ions to the pyridine monomers I containing acyl or the pyridine monomers I containing amidogen is 1-2: 1-2; thirdly, the solvent is removed, and the remaining obtained solid substances are dried for 8-24 hours at 80-100 DEG C; fourthly, mixed gas is introduced for heating, and primary heat treatment is performed; and fifthly, aftertreatment then is performed after temperature lowering, and the product is obtained. Active metal atoms of the non-noble metal catalyst prepared through the preparation method are evenly dispersed in a catalyst material, no metal-metal bonds exist, the metal utilizing rate reaches up to 100%, and the non-noble metal catalyst has the beneficial effects of being good in electric conduction performance, high in specific surface area, few in surface defect and the like.

Owner:GUANGXI UNIV

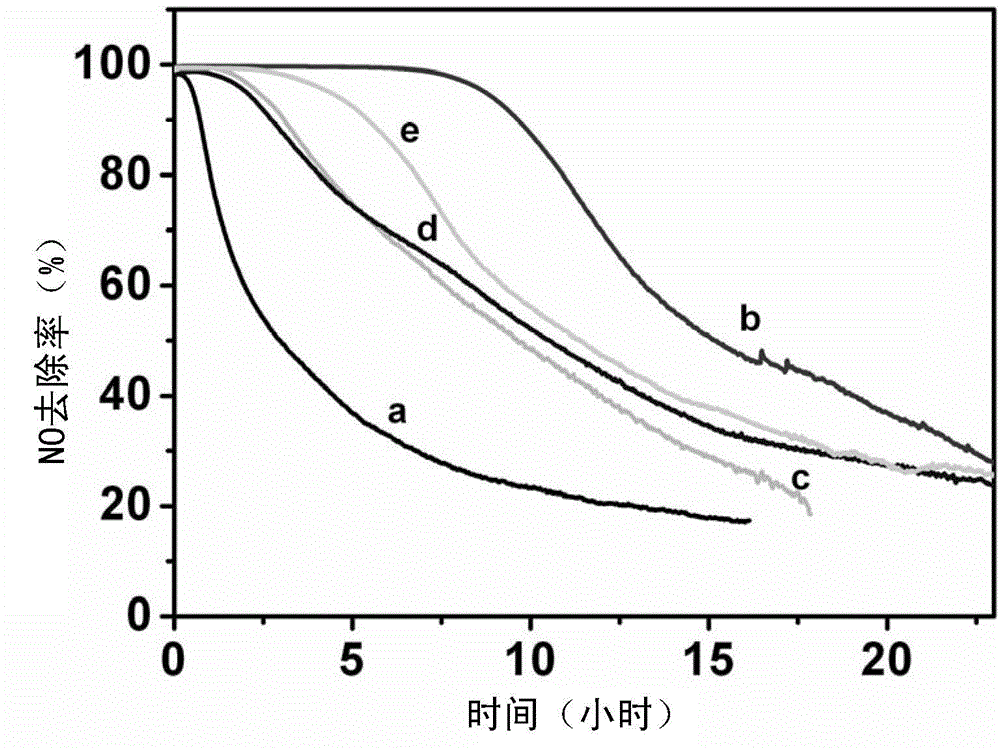

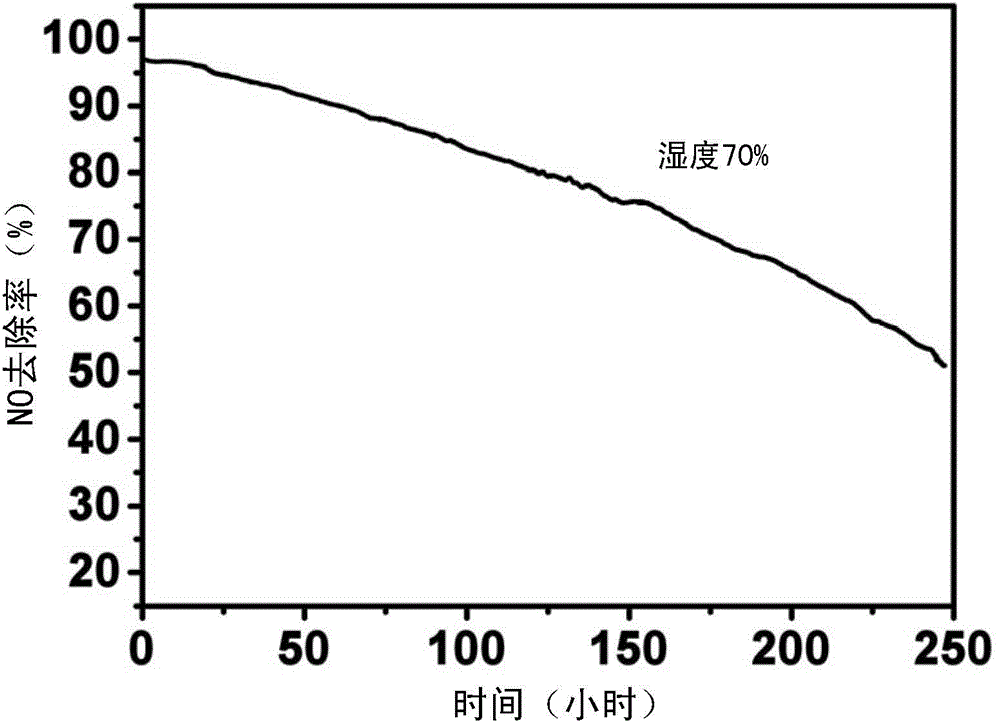

Nano manganese oxide molecular sieve for room temperature efficient nitrogen oxide removal and preparation method thereof

InactiveCN104923281ALarge specific surface areaHigh adsorption storage capacityMolecular sieve catalystsDispersed particle separationMolecular sieveAlkaline earth metal

The present invention relates to a nano manganese oxide molecular sieve for room temperature efficient nitrogen oxide removal and a preparation method thereof. The nano manganese oxide molecular sieve is prepared by doping a nano manganese oxide matrix with 0 to 30% by weight of an alkaline earth metal ion; the specific surface area of the nano manganese oxide molecular sieve is 160-270m<2 > / g; and the nano manganese oxide molecular sieve has surface oxygen vacancies. The nano manganese oxide molecular sieve has a high specific surface area, and thus having high nitrogen oxide adsorption storage capacity. The nano manganese oxide molecular sieve also has many surface defects (surface oxygen vacancies), and the surface defects can be used as catalytically active sites to enhance catalytic performance. Furthermore, by doping of the alkaline earth metal ion, the nano manganese oxide molecular sieve alkaline is enhanced, and acid nitrogen oxide adsorption storage capacity is enhanced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

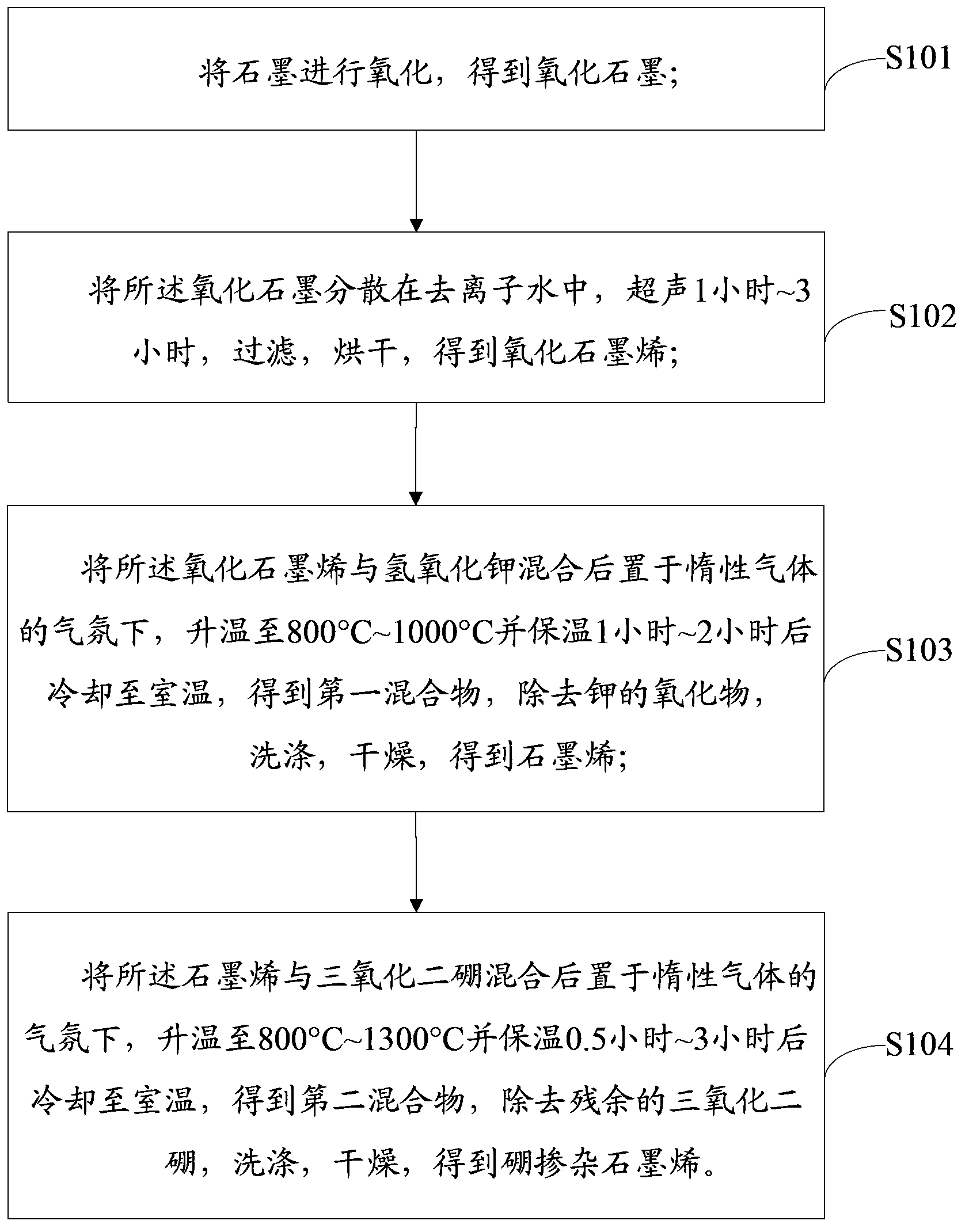

Preparation method of boron doped graphene

A preparation method of boron doped graphene comprises the steps of: oxidizing graphite to obtain the graphite oxide; dispersing the graphite oxide in deionized water, conducting ultrasonic treatment for 1-3 h, filtering and drying to obtain the graphene oxide; mixing the graphene oxide with potassium hydroxide, placing the mixture in an inert gas atmosphere, heating to 800-1000 DEG C, insulating for 1-2 h, and cooling to room temperature to obtain a first mixture; removing oxides of potassium, washing and drying to obtain graphene; mixing the graphene with boron trioxide, placing the mixture in an inert gas atmosphere, heating to 800-1300 DEG C, insulating for 0.5-3 h and cooling to room temperature to obtain a second mixture; and removing residual boron trioxide, washing and drying to obtain boron doped graphene. By adopting the preparation method, boron doped graphene with high boron content can be obtained.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Weather-proof anti-ultraviolet nylon material and preparation method thereof

The invention provides a weather-proof anti-ultraviolet nylon material and a preparation method thereof, and relates to the field of polymer materials. The nylon material comprises the following components in parts by weight: 50-70 parts of caprolactam, 3-5 parts of a polyethylene and polyolefin elastomer mixture grafted with maleic anhydride, 3-5 parts of an ethylene-propylene-diene monomer (EPDM) grafted with maleic anhydride, 10-20 parts of a polyethylene and EPDM mixture grafted with maleic anhydride, 0.3-0.5 part of epoxy resin, 5-15 parts of thermosetting resin, 5-8 parts of a carbon fiber, 1-3 parts of 2,4-toluene diisocyanate, 1-3 parts of sodium hydroxide, 1-3 parts of nanometer zinc oxide, 0.5-1.5 parts of diphenylmethane diisocyanate, 2-5 parts of a flame retardant, 1-3.5 parts of a solid lubricant, 0.5-2 parts of a TDI curing agent, 0.5-1.5 parts of a plasticizer, 0.5-1.5 parts of a flexibilizer, 0.5-2 parts of a heat stabilizer and 0.2-0.5 part of benzotriazole. The nylon material is high in airtightness, heat stability and dimensional stability, and relatively high in stretching rate.

Owner:高瑞杰

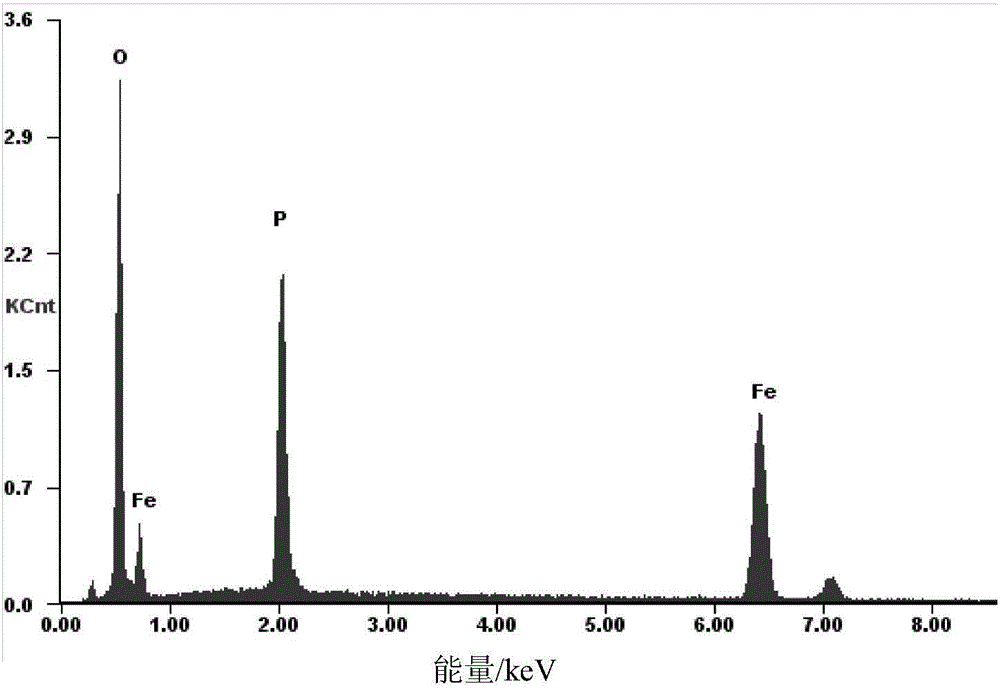

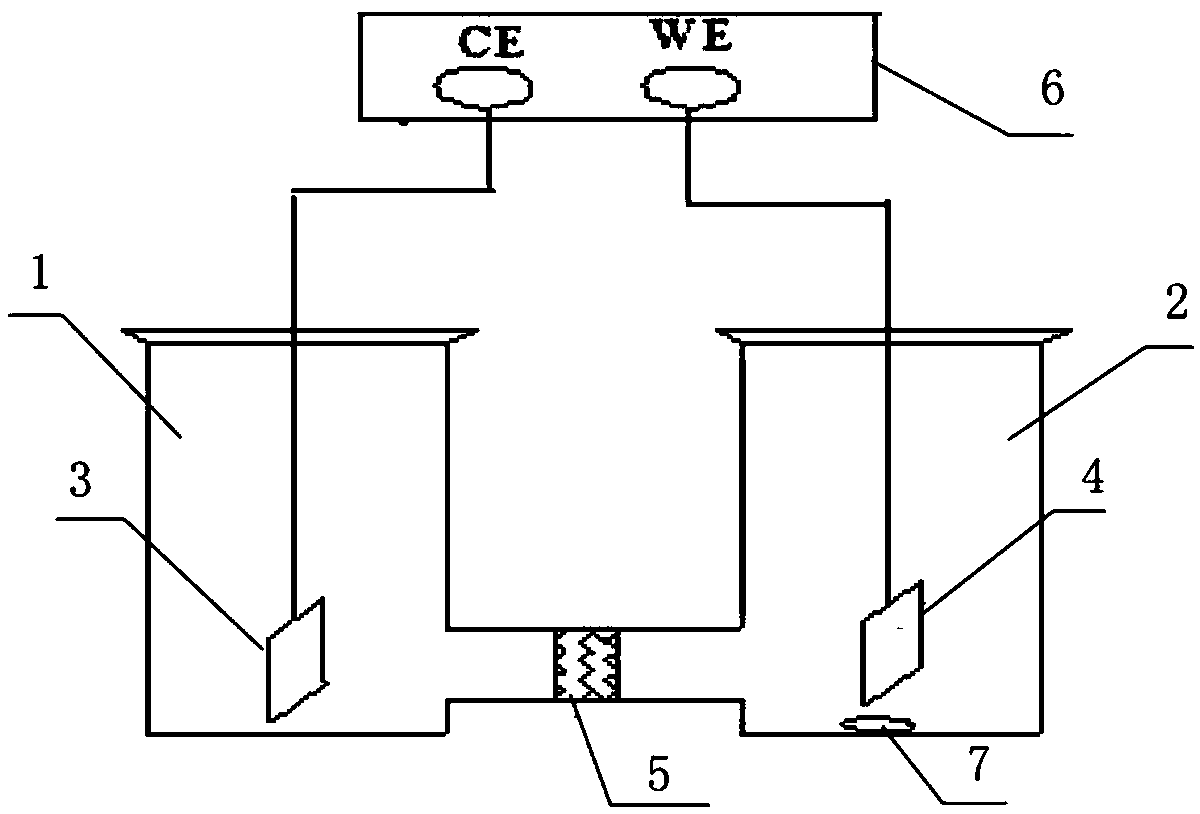

Dandelion-shaped iron phosphate microspheres and preparation method thereof through electrochemical anode oxidation

InactiveCN103556169ASynthesis temperature is lowShort synthesis timeElectrolysis componentsAnode oxidationIron phosphate

The invention discloses dandelion-shaped iron phosphate microspheres and a preparation method thereof through electrochemical anode oxidation, relating to dandelion-shaped iron phosphate microspheres and a method for preparing the dandelion-shaped iron phosphate microspheres through electrochemical anode oxidation, and aiming to solve the problems that iron phosphate micro nanoparticles prepared by the prior art are long in synthesis time, high in synthesis temperature and complex in operation step. The method disclosed by the invention comprises the steps of preparing a mixed solution of phosphoric acid and ammonium fluoride of a certain molar concentration to serve as electrolyte for anode oxidation, and generating the dandelion-shaped iron phosphate microspheres on the surface of an iron foil under conditions of certain current by taking a high-purity iron foil as an anode and a platinum sheet as a cathode. The iron phosphate obtained by the invention is used as a precursor when being used for preparing lithium iron phosphate.

Owner:HARBIN INST OF TECH

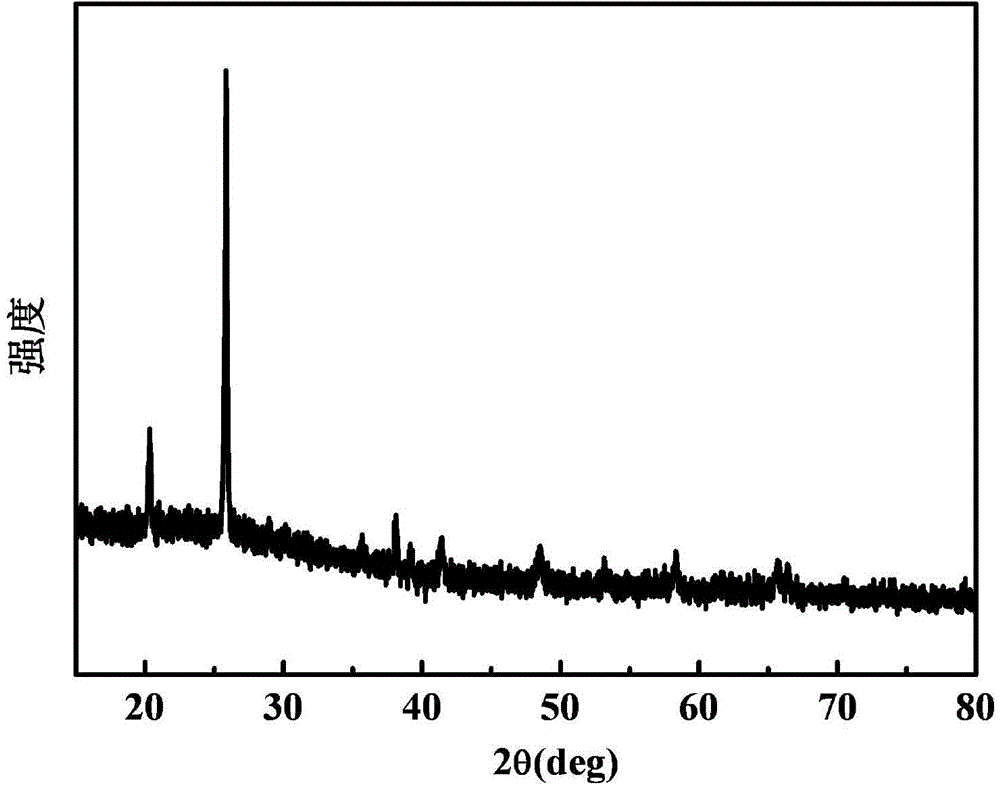

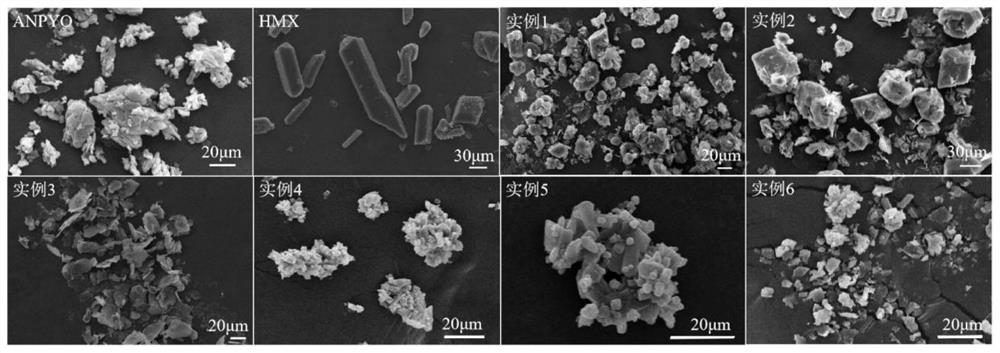

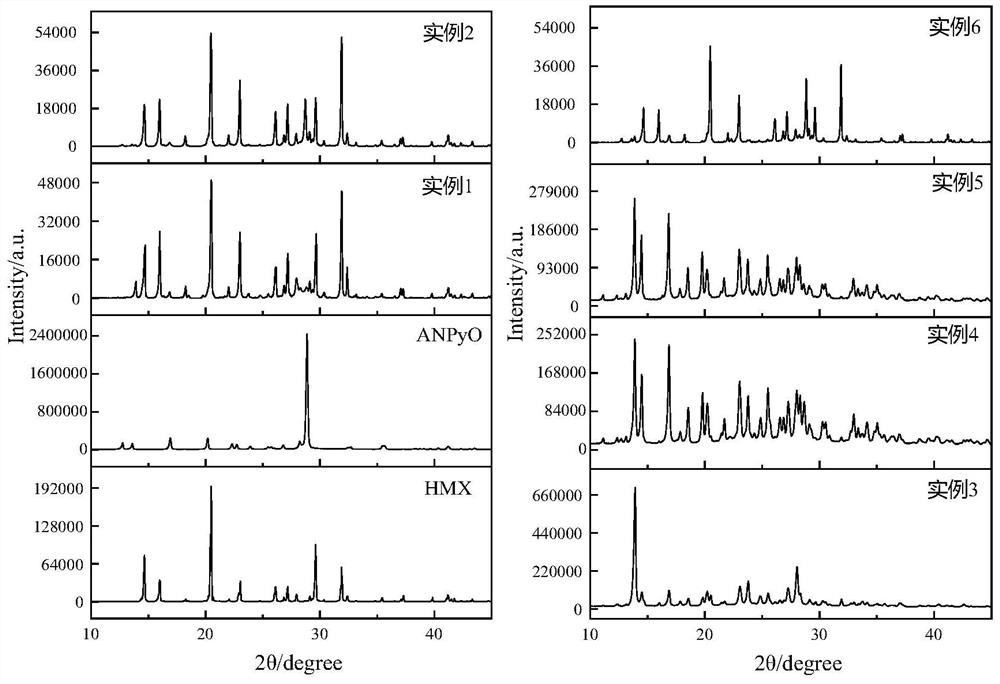

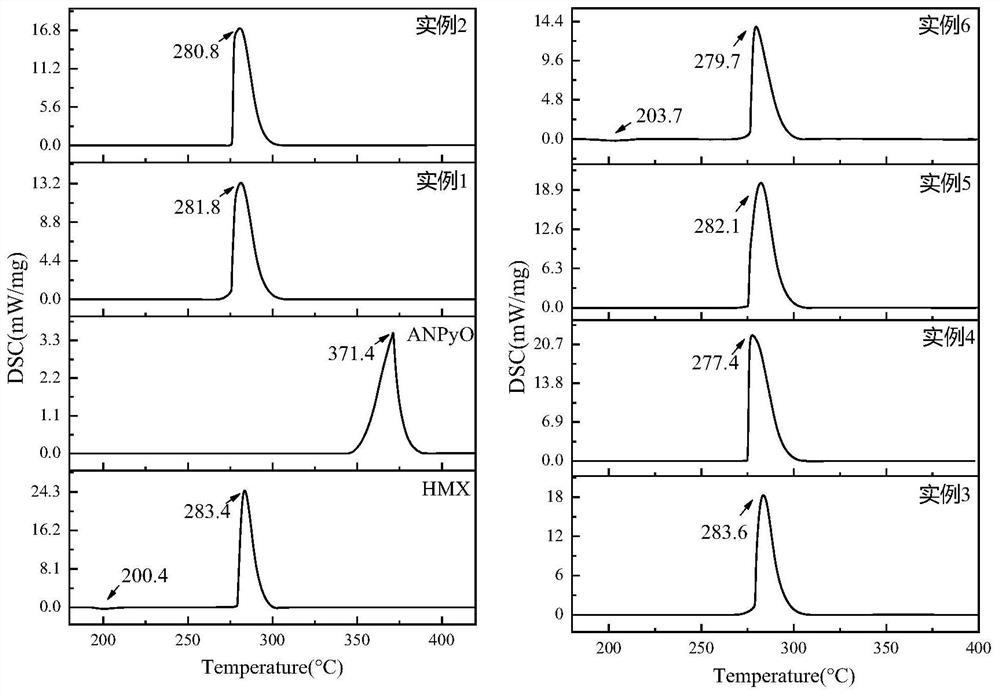

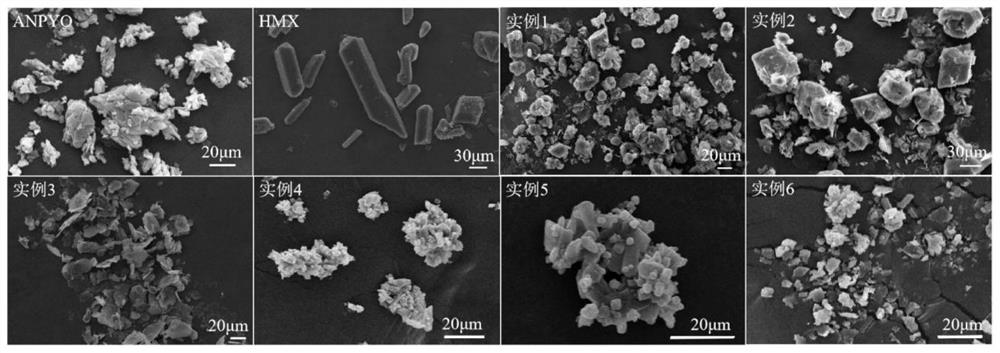

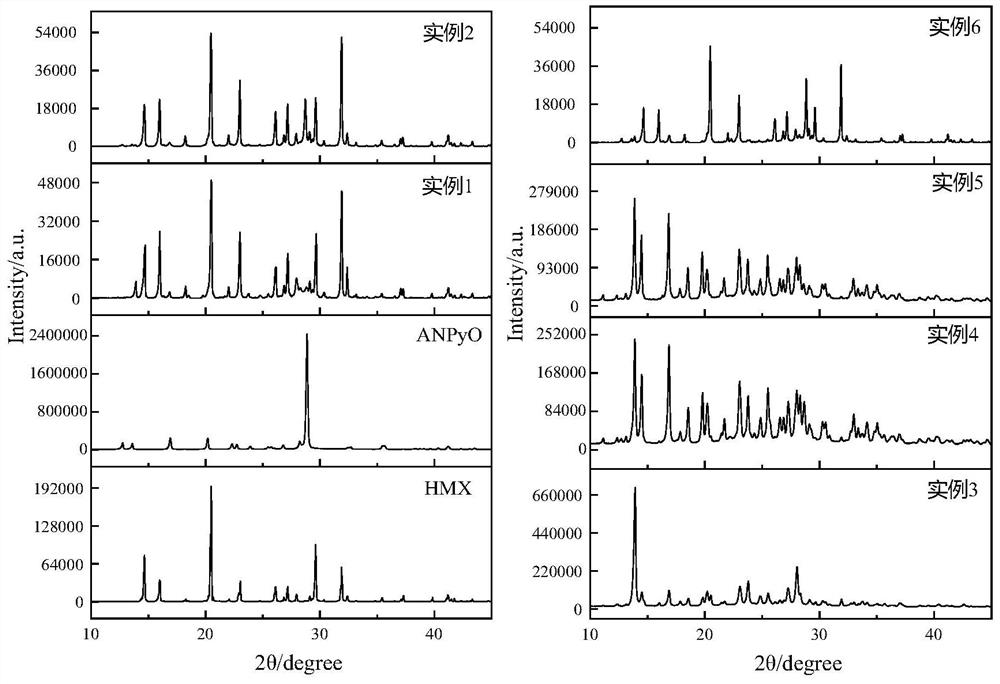

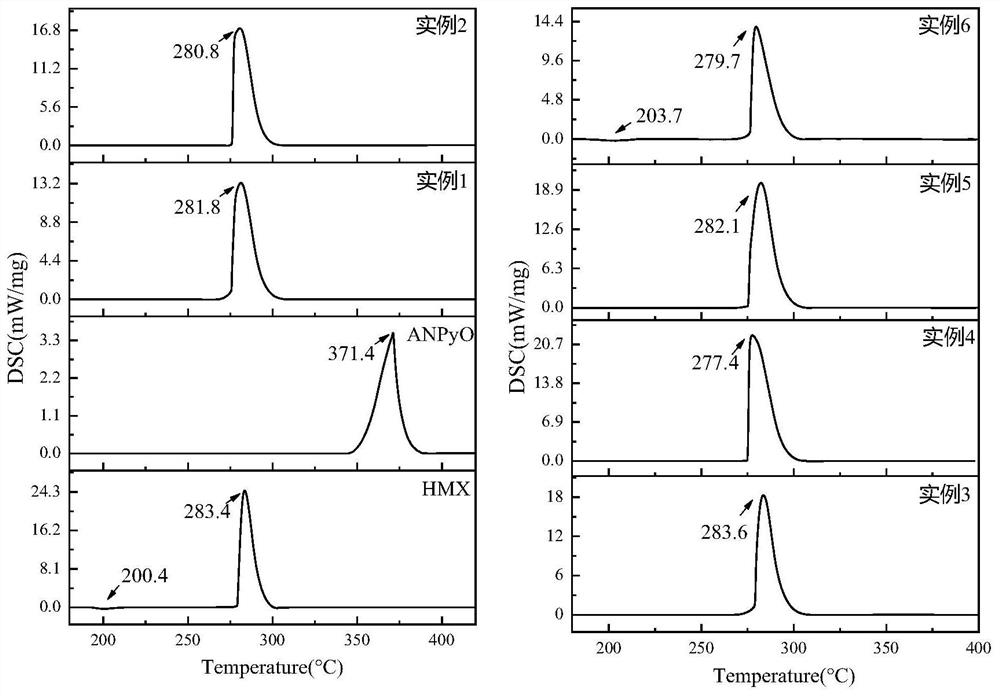

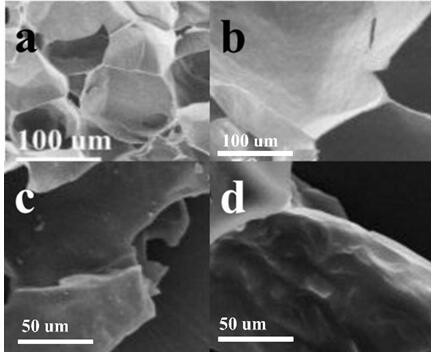

Preparation method of HMX/ANPyO eutectic crystal under two-dimensional material confinement doping condition

ActiveCN112266311ALow costSimple methodNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingChemical physicsPhysical chemistry

The invention relates to a preparation method of an HMX / ANPyO eutectic crystal under a two-dimensional material confinement doping condition. The method comprises the following steps: mixing triaminoguanidine nitrate (TAGN) with dimethyl sulfoxide (DMSO), adding HMX and ANPyO until HMX and ANPyO are completely dissolved, and adding glyoxal to obtain a two-dimensional conjugated structure material;and growing HMX / ANPyO on the two-dimensional conjugated structure to obtain the HMX / ANPyO eutectic under the confinement doping condition. The method is simpler, the final material structure and performance can be accurately controlled through reaction conditions and the doping amount, the product yield is high, the cost of used raw materials is low, and industrial production can be easily achieved. Secondly, under the condition of confinement doping of the two-dimensional material, the crystal rigidity and the molecular ordered stacking density of the two-dimensional material are improved, and the detonation performance of the two-dimensional material is further improved. Finally, under the condition of confinement doping of the two-dimensional material, HMX and ANPyO can form eutectic in any proportion, and the experimental conditions are easy to control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pressure-resistant sintered brick

The invention discloses a pressure-resistant sintered brick, and belongs to the field of building materials. The method comprises the following steps of: mixing the blast furnace slag with sulfate solution; freezing and crushing the mixture to improve the dispersibility of the blast furnace slag, wherein SiO2 contained in the blast furnace slag can act with CO2 at high temperature to generate silicon carbide to play a reinforcing role; introducing water vapor, oxidizing the silicon carbide to generate pores for SiO2, alternately improving the structural stability, and improving the pressure resistance; coating, granulating and sintering by using a coating liquid containing potassium permanganate components, wherein the internal metal components can be melted at high temperature to generatemetal oxides, the fluidity of the metal oxides can improve the bonding strength among the internal components, and nano SiO2, nano Al2O3 and nano Fe are used as a substrate layer, the composite bonding material and the gecko-imitating carbon nano-tube structure are manufactured, so that the improvement of pressure resistance is ensured. The pressure-resistant sintered brick solves the problem that the prior sintered brick has poor pressure resistance due to poor balance of the self structure to porosity and internal mechanical property.

Owner:张永华

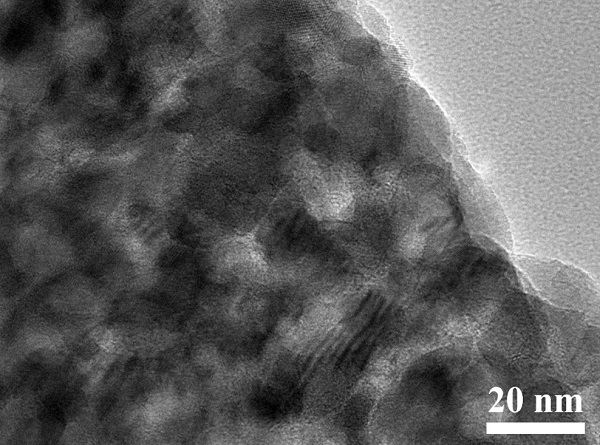

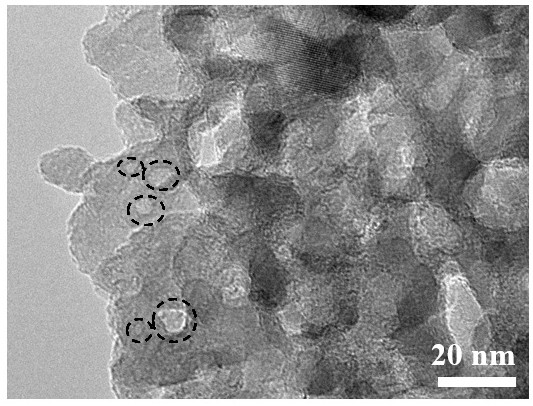

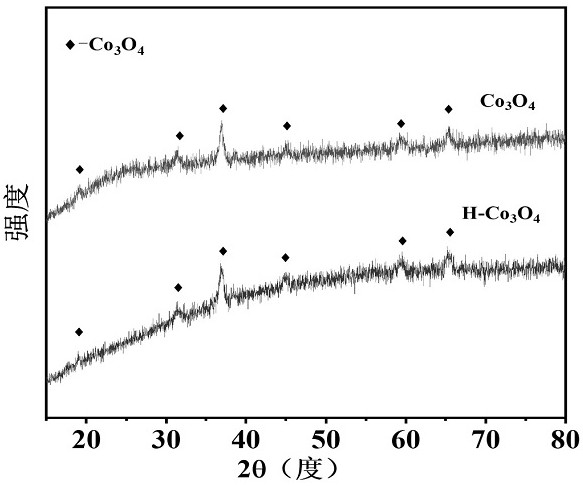

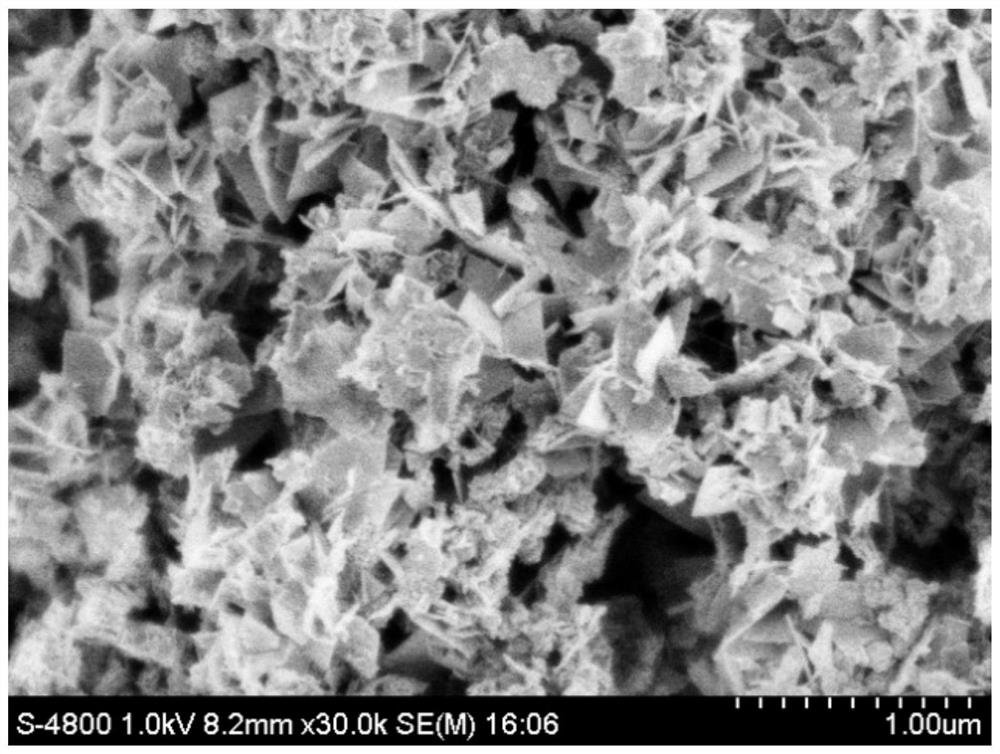

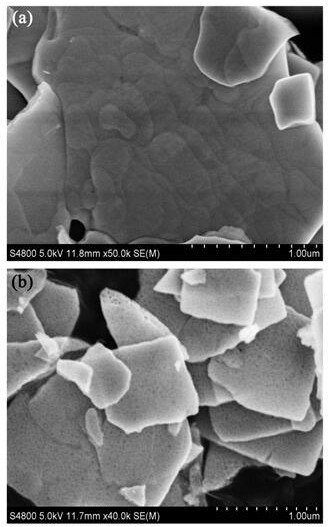

High-defect cobaltosic oxide catalyst for catalytic oxidation of formaldehyde as well as preparation method and application thereof

ActiveCN112264016AImprove catalytic oxidation performanceLarge specific surface areaIncinerator apparatusCobalt oxides/hydroxidesAcid etchingHydration reaction

The invention discloses a high-defect cobaltosic oxide catalyst for catalytic oxidation of formaldehyde as well as a preparation method and application thereof, which belong to the technical field ofpreparation of nano materials. According to the technical scheme, the preparation method comprises the following steps: (a) preparing flaky cobaltosic oxide; (b) performing acid etching on the flaky cobaltosic oxide to obtain the high-defect catalyst: adding the flaky cobaltosic oxide in the step (a) into a diluted hydrochloric acid solution, and then stirring, washing and drying to obtain the high-defect cobaltosic oxide for formaldehyde catalytic oxidation. According to the invention, cobalt nitrate hexahydrate is used as a precursor, precipitation reaction is carried out in an alkaline environment, and then roasting is carried out at high temperature to obtain the flaky cobalt oxide; the flaky cobalt oxide is subjected to acid treatment to obtain the high-defect cobaltosic oxide for catalytic oxidation of formaldehyde, and the high-defect cobaltosic oxide has a larger specific surface area, more surface defects and active sites and a more acidic surface, shows excellent catalytic oxidation performance of formaldehyde, and has great potential in the aspect of replacement of noble metal catalysts.

Owner:QINGDAO UNIV

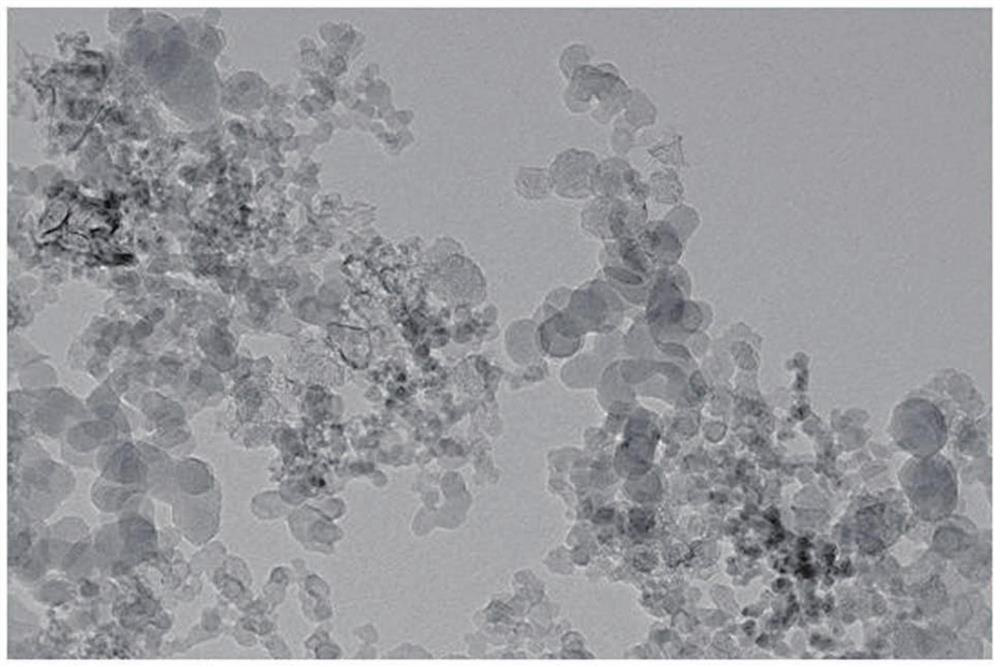

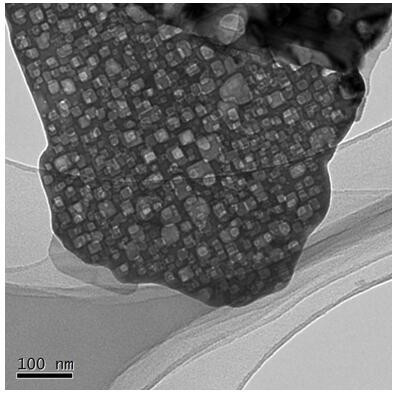

Pd-doped rGO/ZnO-SnO2 heterojunction quaternary composite material as well as preparation method and application thereof

ActiveCN113830753AHigh resistance stateHigh hydrogen responseMaterial nanotechnologyOther chemical processesHeterojunctionHydrogen sensor

The invention relates to a Pd-doped rGO / ZnO-SnO2 heterojunction quaternary composite material as well as a preparation method and application thereof, and belongs to the technical field of gas sensors. The composite material is secondary particles formed by agglomeration of primary particles, the primary particles take rGO of a two-dimensional net structure as a matrix, the surface of the matrix is coated with sheet nanometer materials ZnO and SnO2, ZnO and SnO2 are compounded to form n-n type heterojunctions, ZnO, SnO2 and rGO respectively form p-n type heterojunctions, and Pd nanoparticles are doped in ZnO, SnO2 and rGO. The method comprises the following steps: firstly, mixing a flaky ZnO nano material and stannous chloride in water, sequentially adding DMF, sodium hydroxide and palladium chloride to obtain a mixed solution, then carrying out hydrothermal reaction on the mixed solution and a graphene oxide dissociation solution, and finally calcining. The composite material has the characteristics of high selectivity, quick response and low-concentration detection when being used in the hydrogen sensor.

Owner:AEROSPACE INFORMATION RES INST CAS

Iron core cleaning method used for winding thick silicon steel strip with thickness smaller than or equal to 0.1 mm

The invention discloses an iron core cleaning method used for winding a thick silicon steel strip with a thickness smaller than or equal to 0.1 mm. The iron core cleaning method comprises the following steps: cleaning the surface of an iron core with water for a first time; removing water drops on the surface; carrying out spraying type pickling on the cutting surface of the iron core; dropwise adding an acid solution on the surface of the iron core; cleaning with water for a second time; carrying out spraying type alkaline washing; cleaning with water for a third time; carrying out air-cooling by use of nitrogen gas; drying the iron core under a vacuum state; and cleaning a next iron core according to the steps. According to the iron core cleaning method disclosed by the invention, the end surface of the iron core is processed after cutting and grinding, scrap iron adhered between layers is removed through corrosion, a silicon steel layer on the iron core is guaranteed to be not corroded, and the surface of the iron core does not get rusty after being cleaned. With the adoption of the iron core cleaning method, service cycle is obviously prolonged, a product qualification rate is increased to be 95% or higher from original 85%; and moreover, end surface electrical resistivity of the iron core achieves 95% or higher of a theoretical value.

Owner:武汉研道科技有限公司

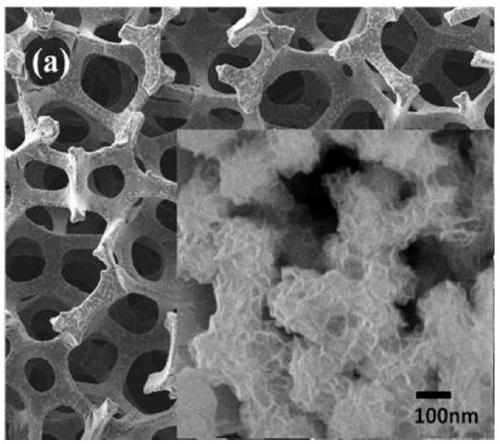

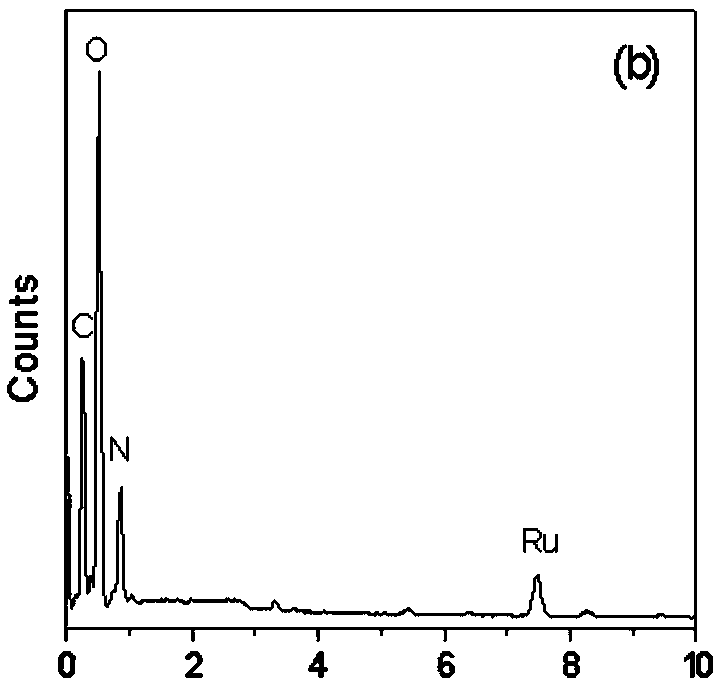

Preparation method and application of amorphous composite electrode for electrocatalytic dechlorination

ActiveCN109534463AMany surface defectsHigh catalytic activity and stabilityWater contaminantsWater/sewage treatment using germicide/oligodynamic-processUltrasonic assistedSimple Organic Compounds

The invention relates to a preparation method and an application of an amorphous composite electrode for electrocatalytic dechlorination, and belongs to the technical field of electrochemical water treatment. The purpose of the invention is to solve the problems of high load, poor electrode stability and high cost of electrode catalysts for electrocatalytic reduction and dechlorination. The preparation method comprises the following steps: pretreatment of a matrix; and preparation of the amorphous composite electrode in a three-electrode electrochemical system under constant current conditionsunder the assistance of ultrasonic waves with the pretreated matrix as the working electrode, NaSO4 as the electrolyte and a noble metal salt and a non-noble metal salt containing N, B or P as a reaction liquid. A method for electrocatalytic reduction and dechlorination treatment of chlorinated organic compounds in water is characterized in that the amorphous composite electrode is used as the working electrode, a Pt piece is used as the counter electrode, a saturated calomel electrode is used as the reference electrode, a constant voltage mode is adopted, a H2SO4 solution is adopted as the anodolyte, and NaSO4 is adopted as the catholyte. The amorphous composite electrode prepared in the invention has the advantages of good conductivity, high catalytic activity, low cost and good stability.

Owner:QINGDAO AGRI UNIV

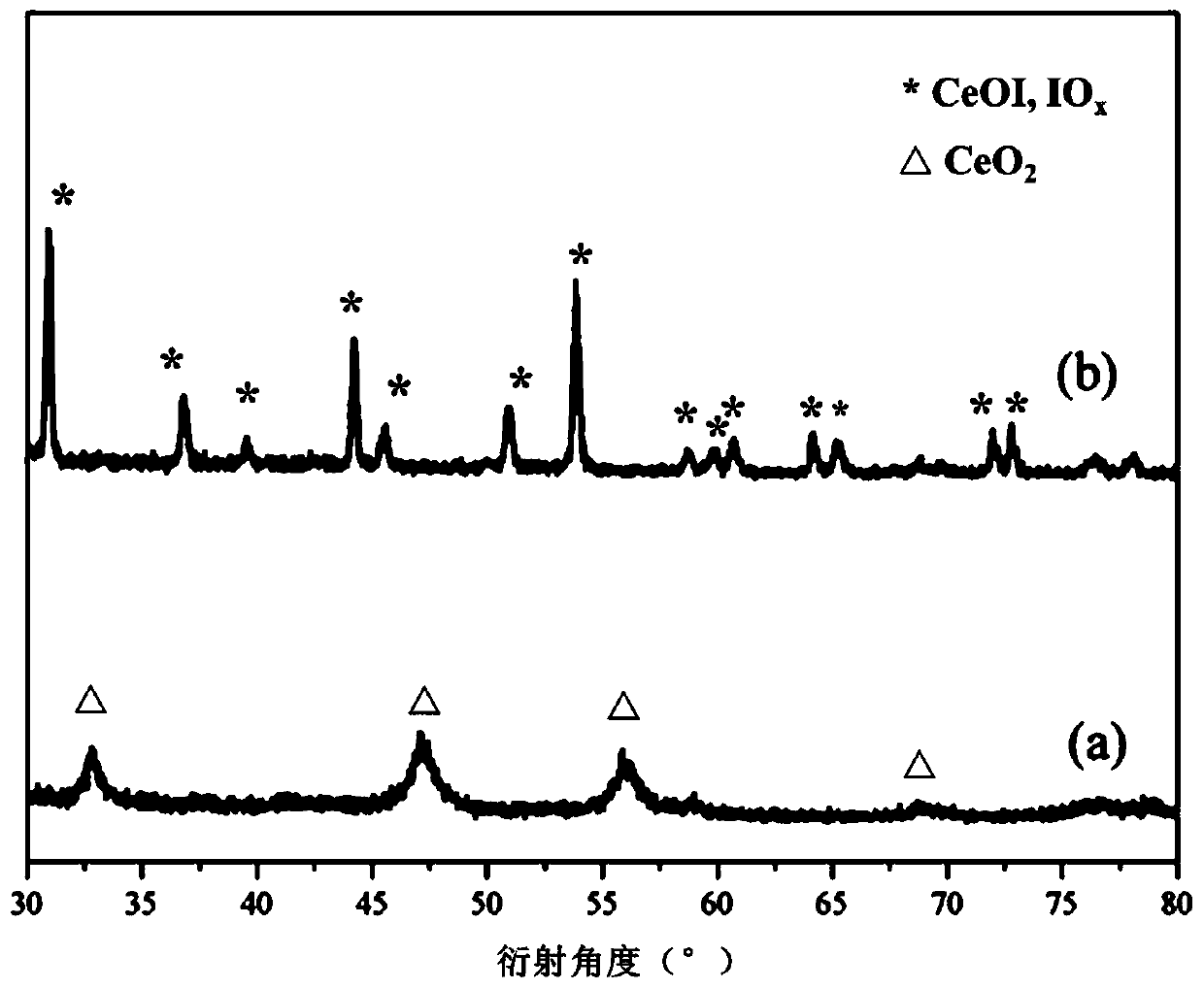

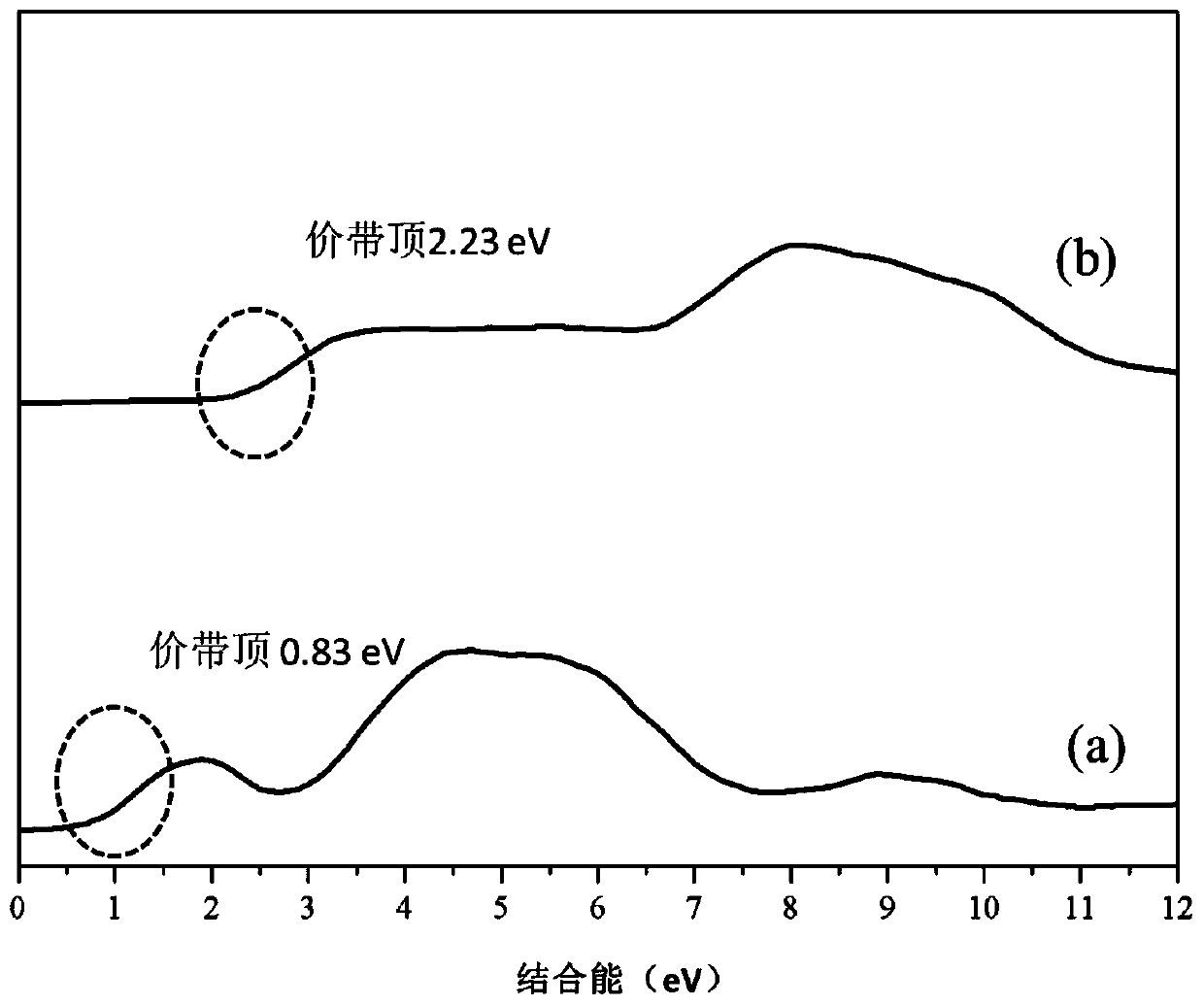

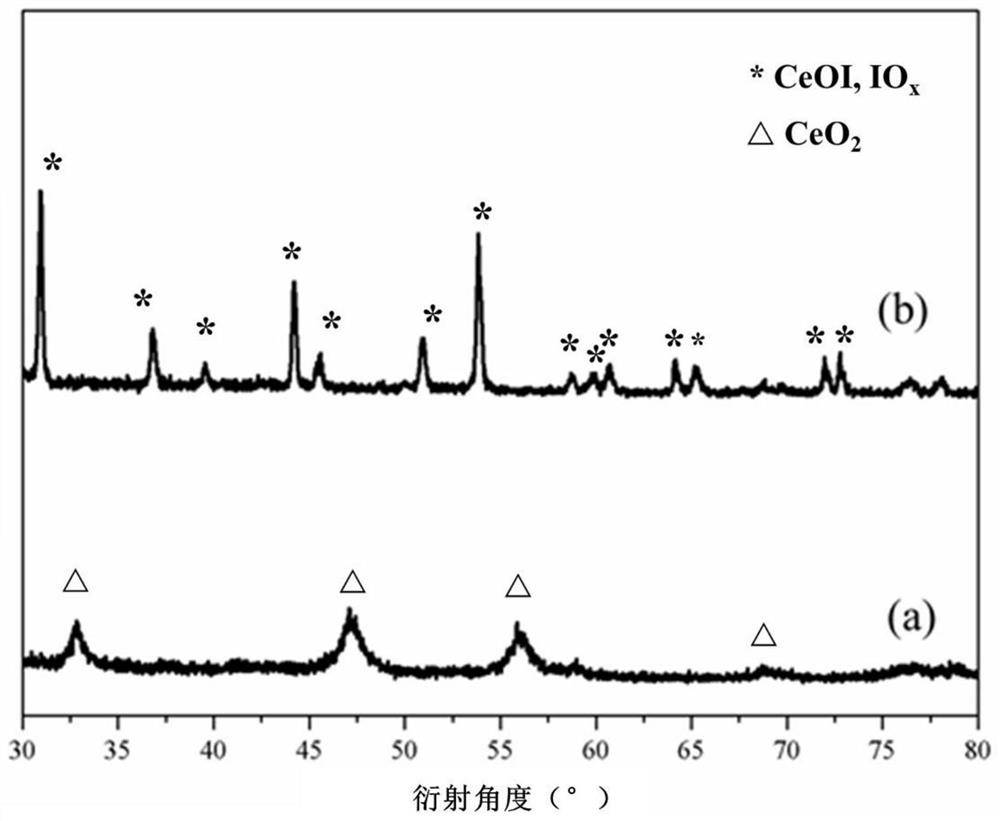

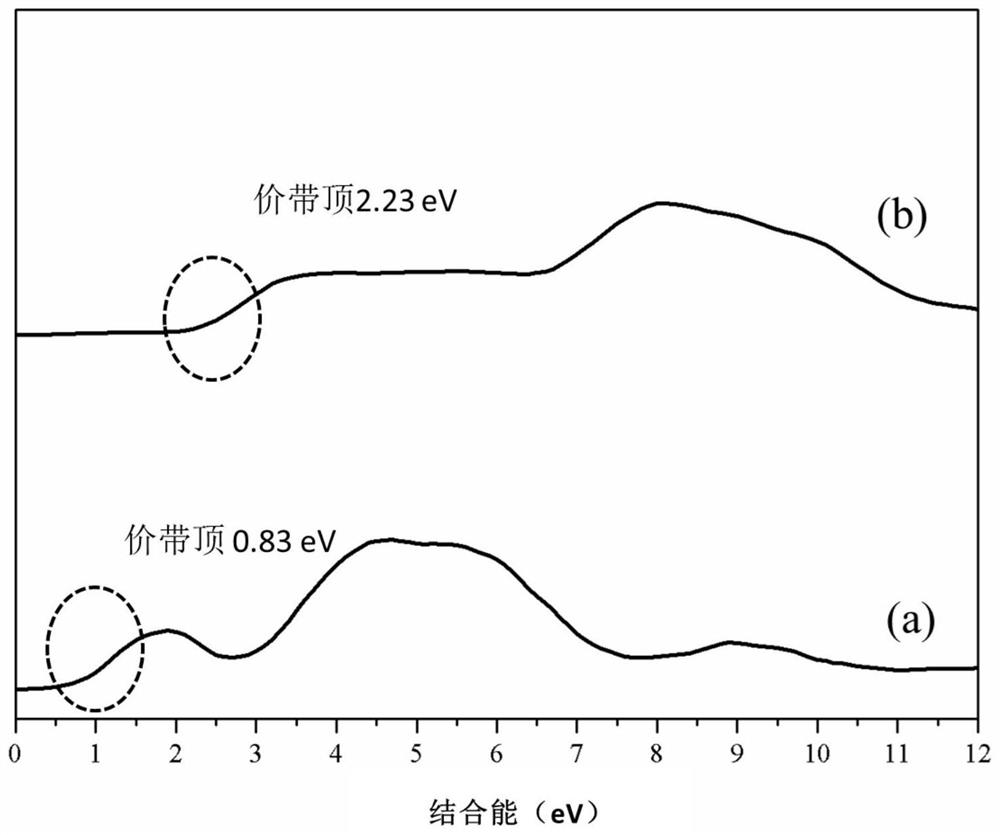

Catalyst for preparing CO by reverse water-gas shift method and preparation method thereof

ActiveCN110479323AImprove efficiencyMany surface defectsPhysical/chemical process catalystsCarbon monoxideCyclic processOxidation reduction

The invention provides a catalyst for preparing CO by a reverse water-gas shift method and a preparation method of the catalyst, the catalyst is represented as Pd-I / CeO2, the mass percentage of Pd is1-4 wt%, and the molar ratio of surface I / Pd is 0.2-0.5. By finely controlling the preparation process of the catalyst, cerium oxide crystal lattices are expanded through chlorine atoms firstly, theniodine atoms are doped into the catalyst, finally, the excessively doped iodine element is removed through the oxidation-reduction cycle process, and the catalyst with the specific structure and performance is obtained. The catalyst is used in a reaction for preparing CO by a reverse water-gas shift method, the conversion rate of CO in a reaction interval of 400-600 DEG C is 26.2-50%, and the selectivity of CO is 97-99%, which are obviously higher than that of existing catalyst.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

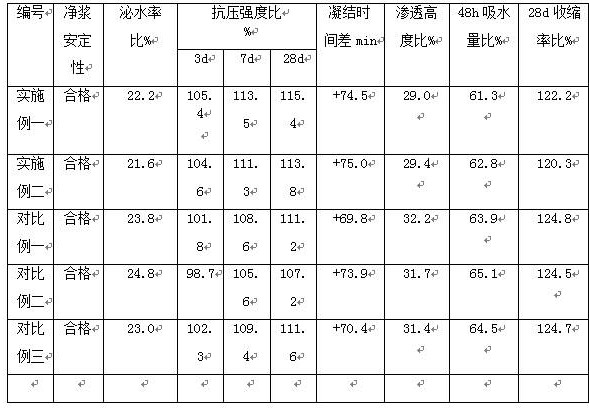

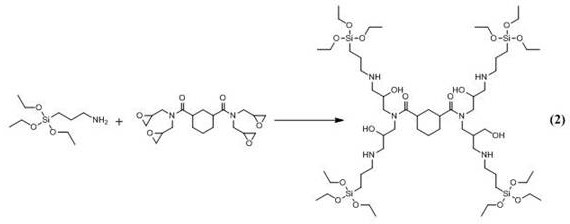

Preparation method of four-arm anti-permeability compacting agent

ActiveCN113200705AImprove compactnessReduce shrinkage cracksGroup 4/14 element organic compoundsCapillary TubingStructural engineering

The invention belongs to the technical field of building concrete admixtures, and particularly relates to a preparation method of a four-arm anti-permeability compacting agent. The prepared anti-permeability compacting agent is introduced in the concrete stirring process to improve the workability of concrete, improve the slump, increase the early strength of the concrete and increase the anti-permeability compactness of the concrete, the concrete strength can be increased at a low temperature, the freeze-thaw resistance of the concrete is also enhanced, in the concrete processing and using process, an anti-permeability compacting agent which takes a four-arm anti-permeability agent prepared from a silicon dioxide alkali liquor slow release and a silane coupling agent as a main raw material is adopted, capillary pores capable of filling the concrete are introduced, therefore, the hardening of the concrete is accelerated, and the anti-permeability compacting is achieved.

Owner:安徽润砼建材科技有限公司

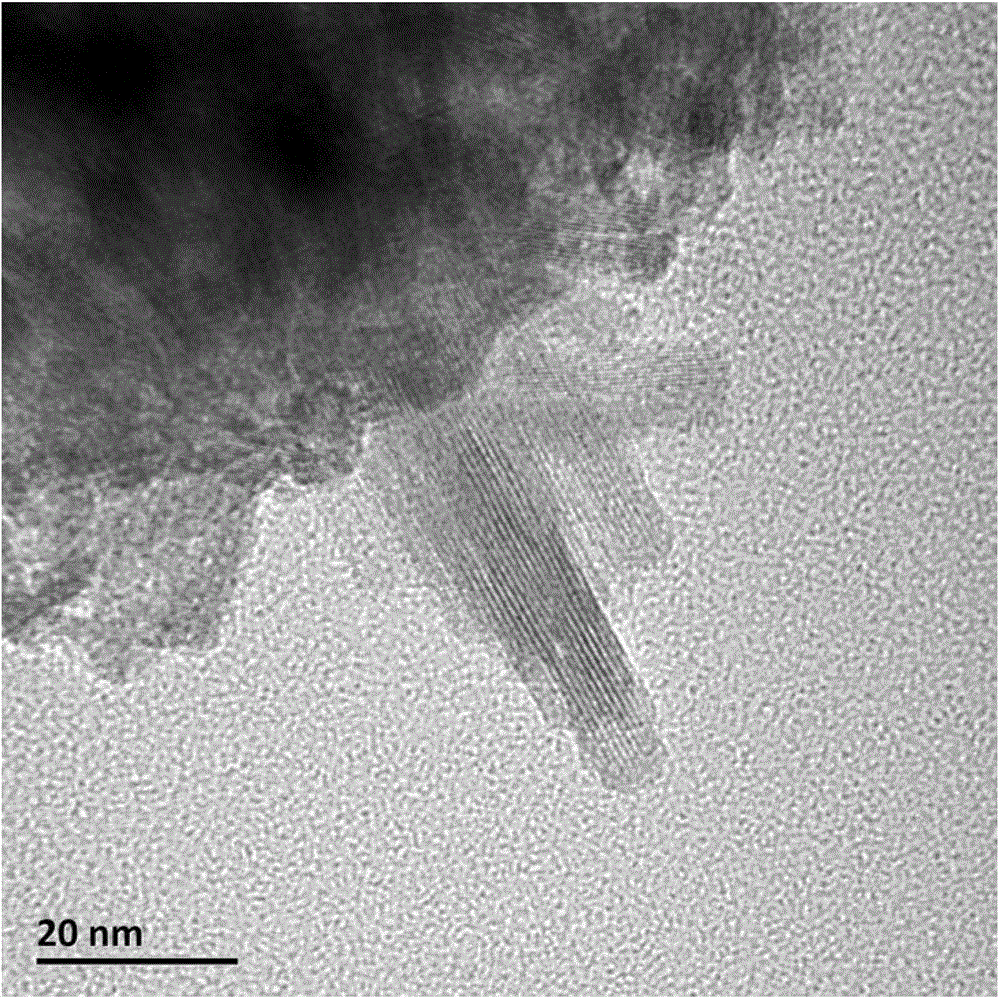

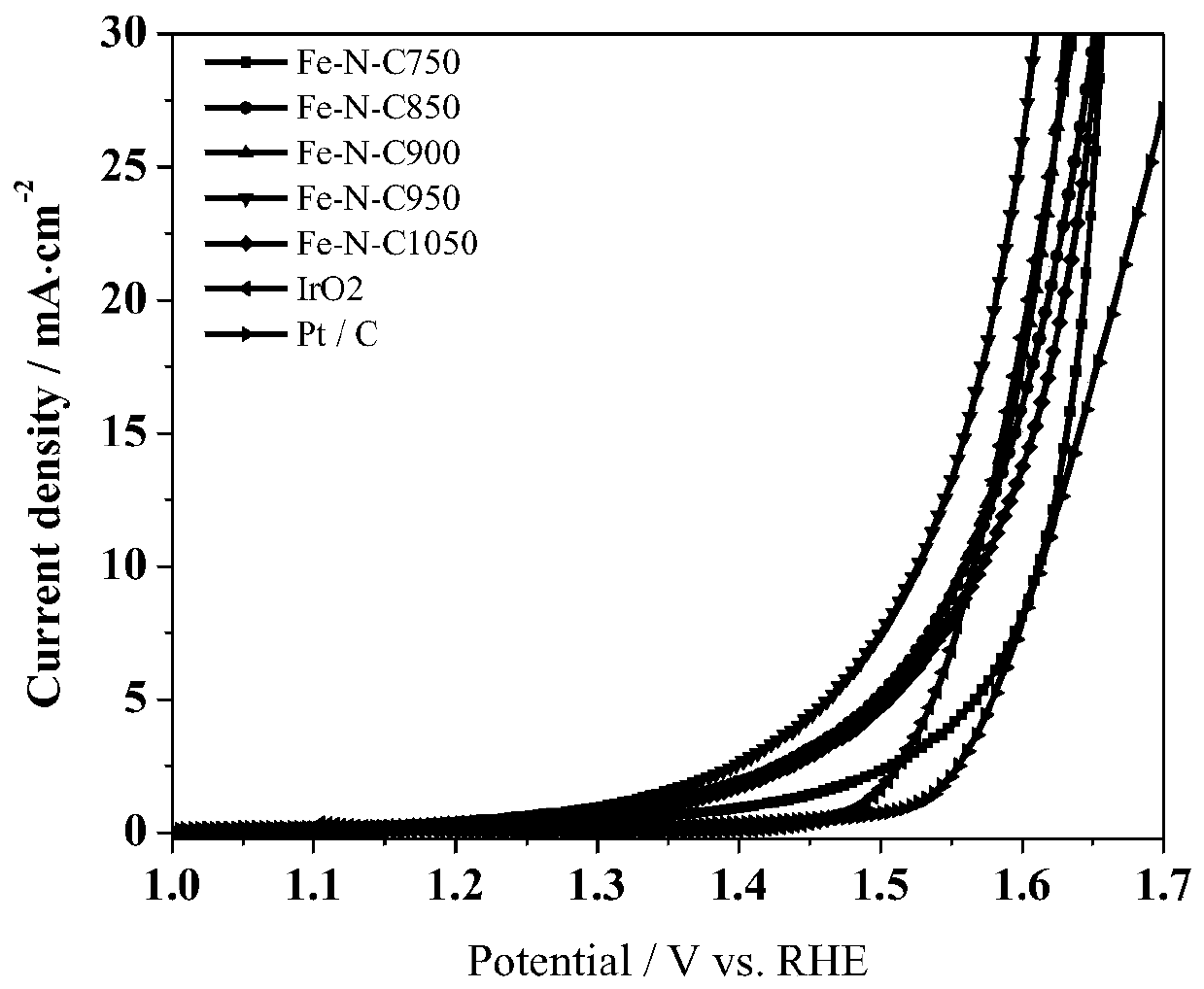

Electrolyzed water catalyst of nonconventional local area structure and preparation method thereof

ActiveCN110302791AHigh oxygen evolution reactivityCost-effectiveHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsUltrasonic assistedOxide

The invention relates to an electrolyzed water catalyst of nonconventional local area structure and a preparation method thereof. In the preparation method, A-position element of perovskite is selectively dissolved by using a method of treatment through an ultrasonic-assisted ferric iron solution, perovskite crystal oxide with small specific surface area is converted into amorphous hydroxide of ananostructure, and the hydroxide has extraordinary local area electron structure and geometric structure, thereby having ultrahigh oxygen precipitation performance. In consideration of pH difference of AB-position elements of a perovskite material, ferric iron with proper acidity is selected as a regulator, material structure is changed, and new active sites are introduced, so that ultrahigh OER activity is caused; the catalyst can be applied in the field of fuel cells, metal-air cells and water electrolysis.

Owner:NANJING UNIV OF TECH

A kind of preparation method of non-precious metal catalyst for hydroelectric desorption of oxygen

The invention discloses a preparation method of a water electrolysis oxygen evolution non-noble metal catalyst. The preparation method includes the steps that firstly, pyridine monomers I containing acyl or pyridine monomers I containing amidogen are added into a solvent, then monomers II containing amidogen or monomers II containing acyl and a catalyst are added in, and synthesis is performed by rising temperature; secondly, metal salt is added in, metal ions are added in for complexing, wherein according to the molar weight of the metal ions, the molar ratio of the metal ions to the pyridine monomers I containing acyl or the pyridine monomers I containing amidogen is 1-2: 1-2; thirdly, the solvent is removed, and the remaining obtained solid substances are dried for 8-24 hours at 80-100 DEG C; fourthly, mixed gas is introduced for heating, and primary heat treatment is performed; and fifthly, aftertreatment then is performed after temperature lowering, and the product is obtained. Active metal atoms of the non-noble metal catalyst prepared through the preparation method are evenly dispersed in a catalyst material, no metal-metal bonds exist, the metal utilizing rate reaches up to 100%, and the non-noble metal catalyst has the beneficial effects of being good in electric conduction performance, high in specific surface area, few in surface defect and the like.

Owner:GUANGXI UNIV

Method for preparing graphene nanowall on large scale

The invention discloses a method for preparing a graphene nanowall on a large scale. The method comprises the following steps: (1) putting a quartz boat filled with foamed nickel and ferrocene into aquartz tube heating zone on a reaction gas inflow end, putting a quartz boat provided with a cleaned and dried stainless steel sheet or steel wire gauze into a quartz tube heating zone near a reactiongas outflow end; (2) heating to 1000-1200 DEG C under the normal pressure and the protection of an inert gas, maintaining the atmosphere of the inert gas, introducing hydrogen and a carbon source gasat the volume ratio of (1:6) to (2:3), and reacting for 1 minute to 3 hours; and (3) closing the carbon source gas and the hydrogen, and cooling a reaction furnace to the room temperature at the atmosphere of the inert gas. The ratio of the surface area to the volume of the graphene nanowall is larger, the edge is sharp, a thin layer is transparent, and the surface defects are rich; the preparation process is simple, the cost is low, the control process is controllable, the method has the advantage of more convenience as compared with the synthesis method like PECVD (Plasma Enhanced ChemicalVapor Deposition), and the graphene nanowall is produced on a large scale.

Owner:NANCHANG UNIV

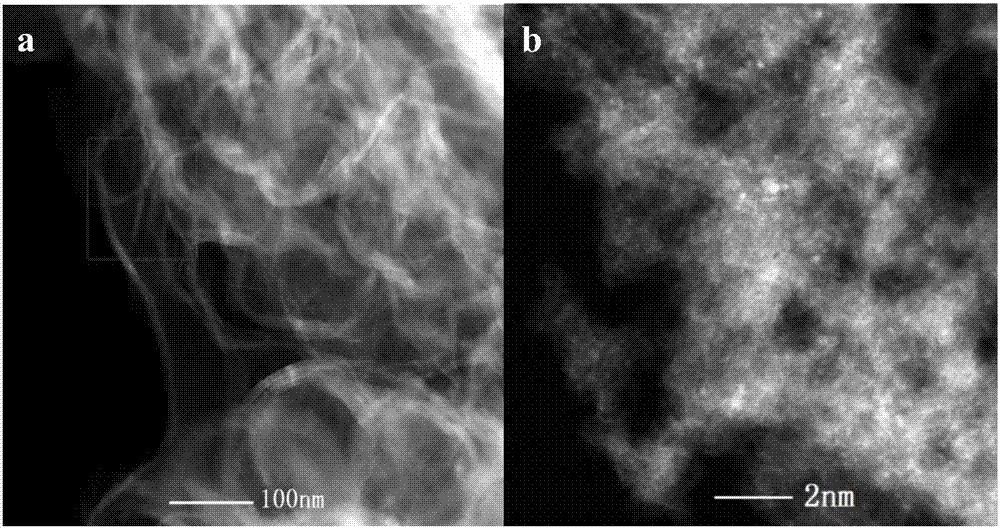

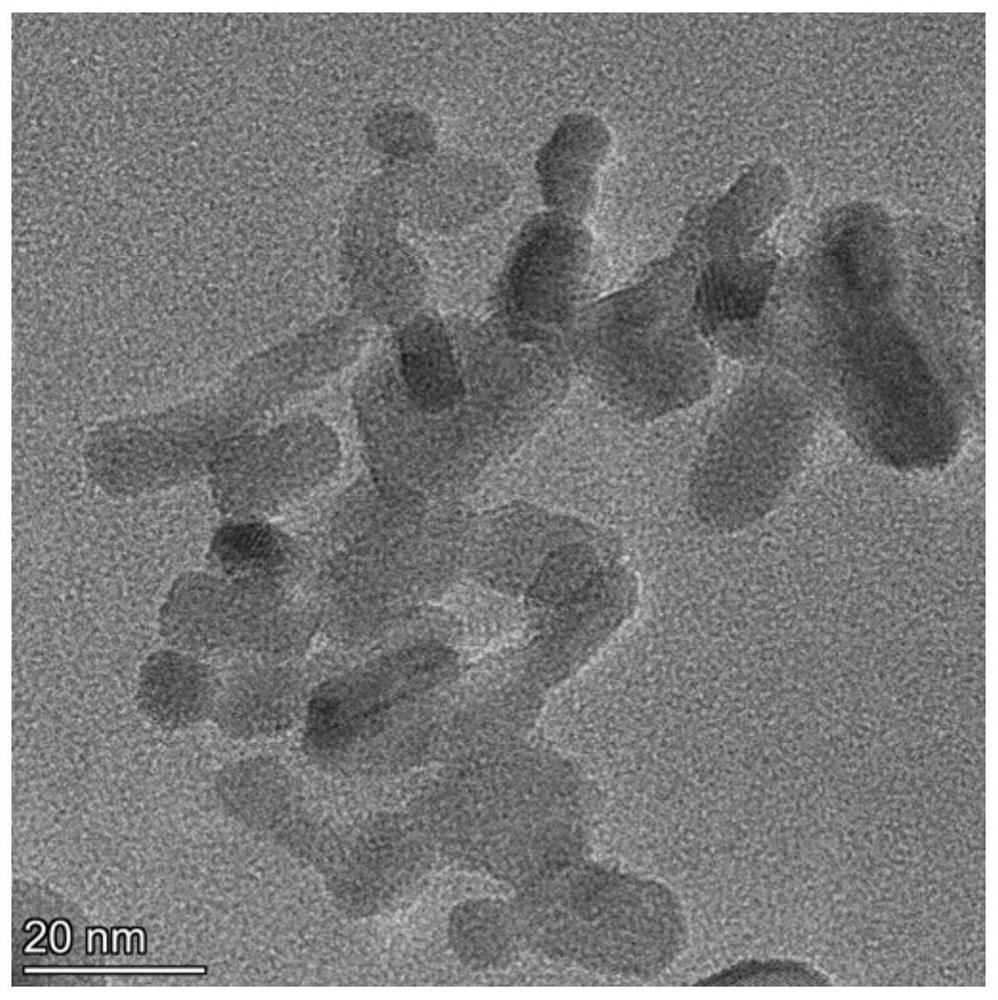

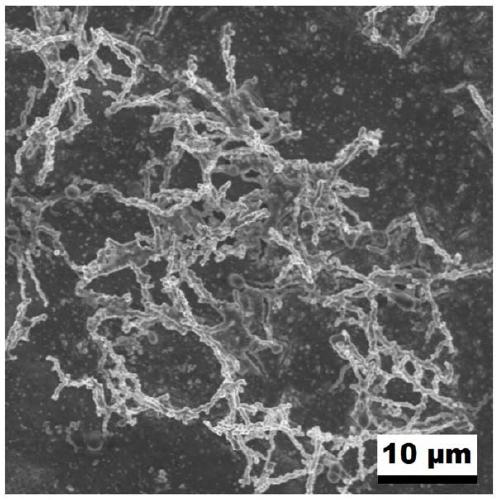

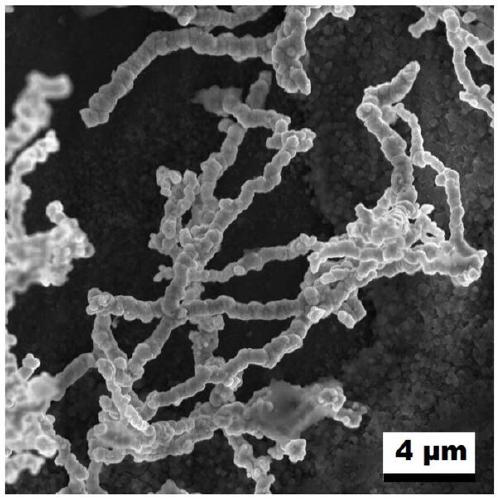

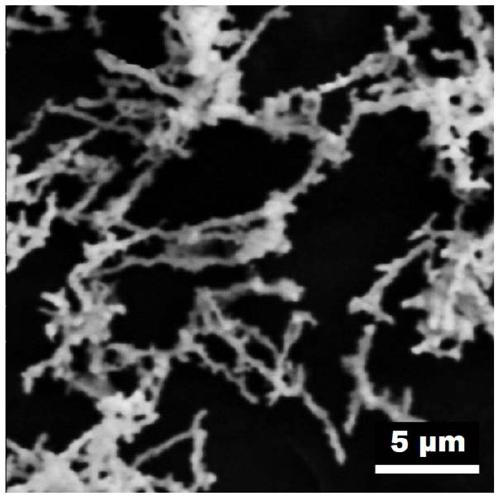

Preparation method of au-ir nanochain electrocatalyst for water splitting and oxygen production

InactiveCN108588740BMany surface defectsLarge specific surface areaNanotechnologyElectrodesIridiumOxygen

The invention discloses a preparation method of a gold-iridium nanoparticle chain electrocatalyst used in the oxygen production process adopting water splitting reaction, and belongs to the technicalfield of electrocatalysis and energy. The preparation method is characterized in that potassium bromide is used as a stabilizer, formaldehyde is used as a reducing agent, and chloroauric acid and iridium trichloride are reduced into the gold-iridium nanoparticle chain with a sawtooth-shaped surface by adopting a method that the chloroauric acid and iridium trichloride are heated in an aqueous solution. The gold-iridium nanoparticle chain obtained through the preparation method has a unique one-dimensional structure and rich active sites and has relatively high activity and stability in the catalytic oxygen evolution reaction in an alkaline medium, so that the gold-iridium nanoparticle chain can be used as an oxygen production catalyst through water splitting in an alkaline environment. Thepreparation method of the gold-iridium nanoparticle chain is simple and economic, and is suitable for industrial large-scale production.

Owner:SHANGLUO UNIV

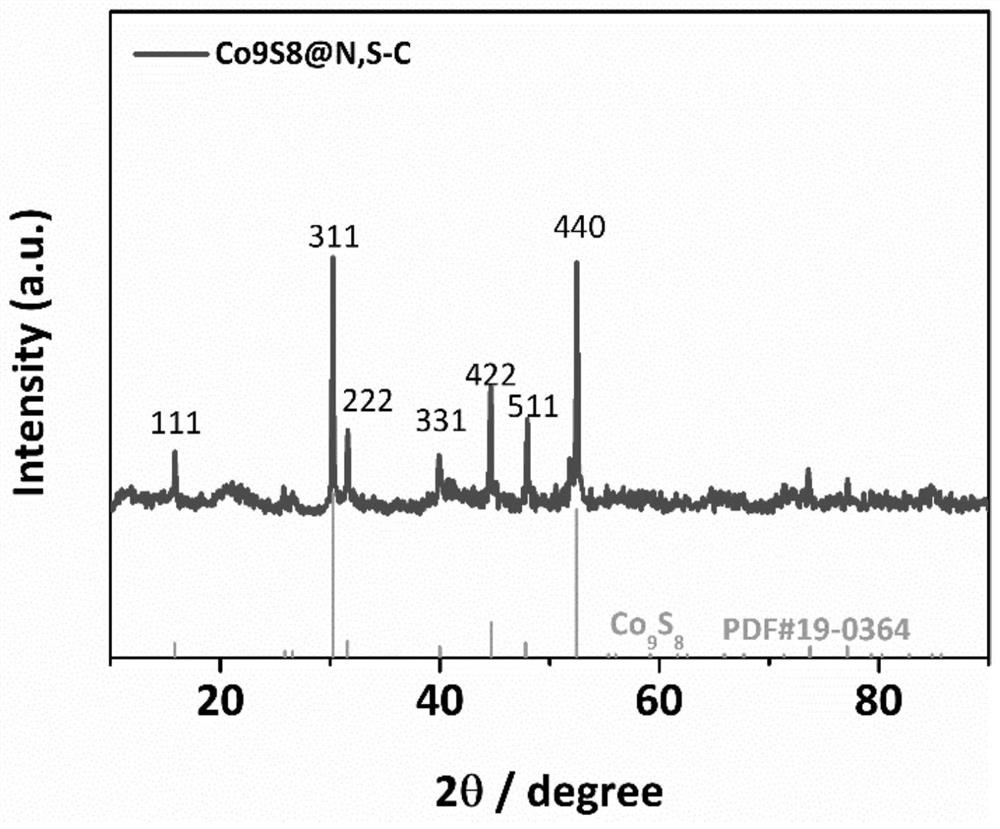

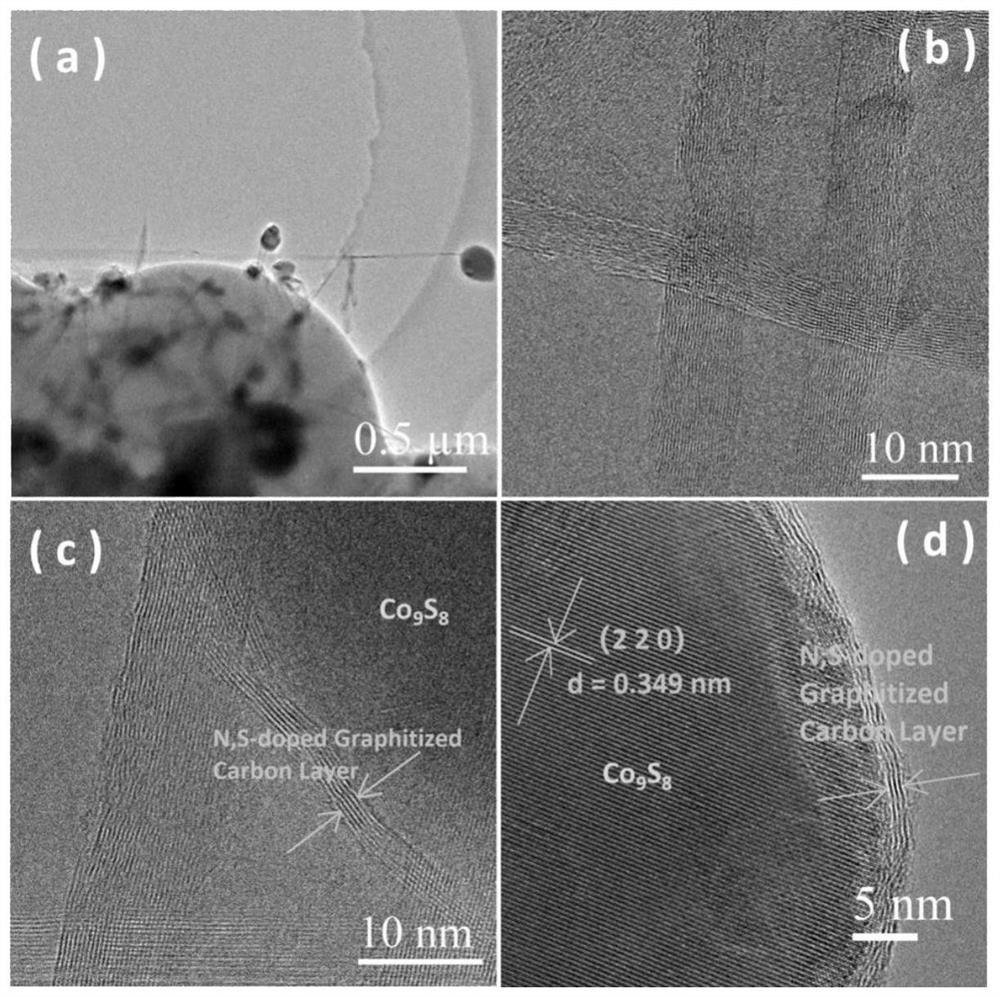

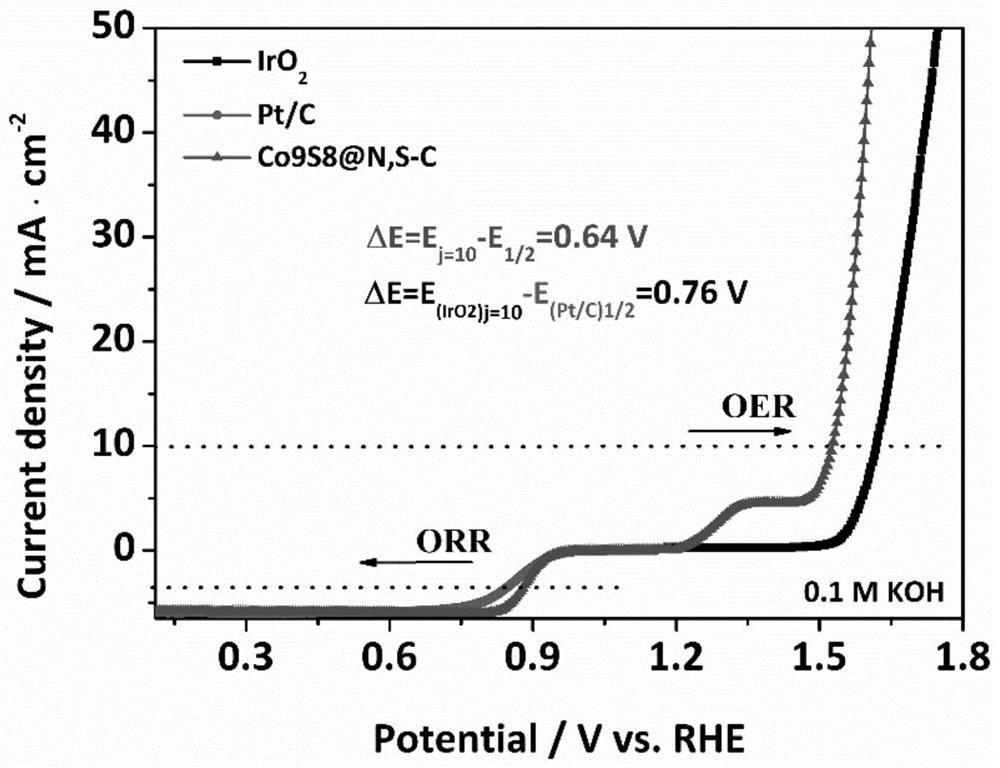

Preparation method of nitrogen-sulfur co-doped carbon-coated transition metal nano sulfide electrochemical oxygen catalyst

ActiveCN113224319AThe earth is rich in reservesLow priceMaterial nanotechnologyCell electrodesCarbon layerInorganic salts

The invention discloses a preparation method of a nitrogen-sulfur co-doped carbon-coated transition metal nano sulfide electrochemical oxygen catalyst. The preparation method comprises the following steps of: (1) taking a 2, 6-diacetylpyridine monomer solution, adding a sulfur-containing amino monomer, performing stirring to realize dissolving, adding acid, performing heating and performing a reaction; (2) performing cooling, adding transition metal-containing inorganic salt for reaction, performing evaporating, drying and grinding; (3) carrying out first thermal cracking, cooling to room temperature, and carrying out acid pickling and drying on an obtained substance; and (4) carrying out second thermal cracking to obtain the nitrogen-sulfur co-doped carbon-coated transition metal nano sulfide electrochemical oxygen catalyst. The nitrogen-sulfur co-doped carbon-coated transition metal nano sulfide electrochemical oxygen catalyst prepared by the invention is composed of transition metal sulfide, carbon, nitrogen and sulfur, has the structural characteristics of highly graphitized carbon layer-coated transition metal sulfide, and also has the advantages of good conductivity, mesoporous and macroporous structure, many surface defects, and high catalytic performance of oxygen reduction and oxygen evolution.

Owner:GUANGXI UNIV

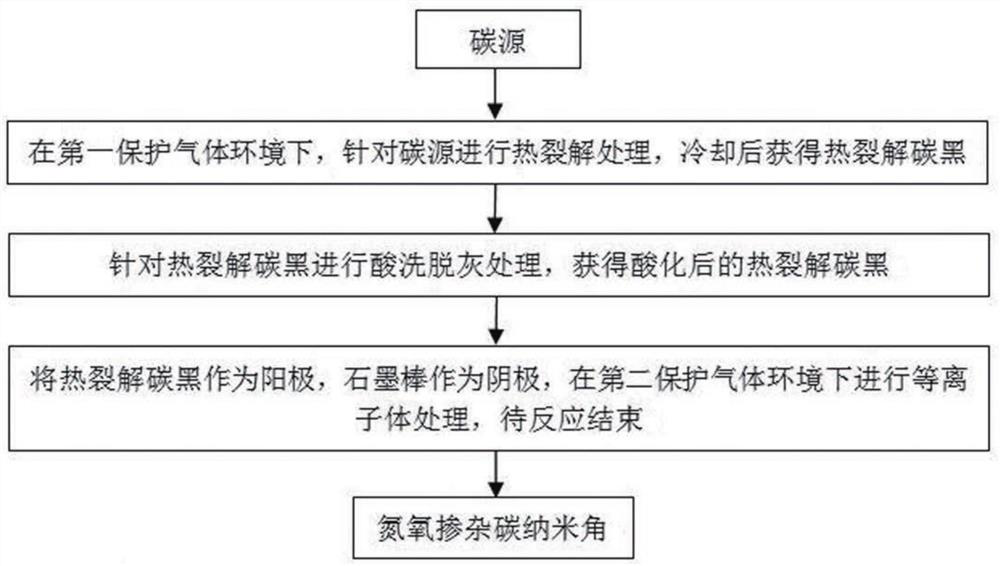

Nitrogen-oxygen-doped carbon nanohorn and preparation method and application thereof

PendingCN114823171ARealize rational useReduce pollutionHybrid capacitor electrodesHybrid/EDL manufacturePtru catalystPlasma treatment

The invention provides a nitrogen-oxygen-doped carbon nanohorn and a preparation method and application thereof.The preparation method comprises the following steps that in a first protective gas environment, thermal cracking treatment is conducted on a carbon source, thermal cracking carbon black is obtained after cooling, and the carbon source is waste tire powder; and taking the thermal cracking carbon black as an anode and a high-purity graphite rod as a cathode, carrying out plasma treatment in a second protective gas environment, and obtaining the nitrogen-oxygen doped carbon nanohorn after the reaction is finished. The nitrogen-oxygen-doped carbon nanohorn is prepared by the preparation method, and can be applied to a supercapacitor. The method has the beneficial effects that the used raw materials are rich, cheap and easy to obtain, the preparation process is simple, easy to operate, short in period, free of introduction of a catalyst and environment-friendly, and a new thought is provided for recovery and utilization of waste tires.

Owner:KUNMING UNIV OF SCI & TECH +1

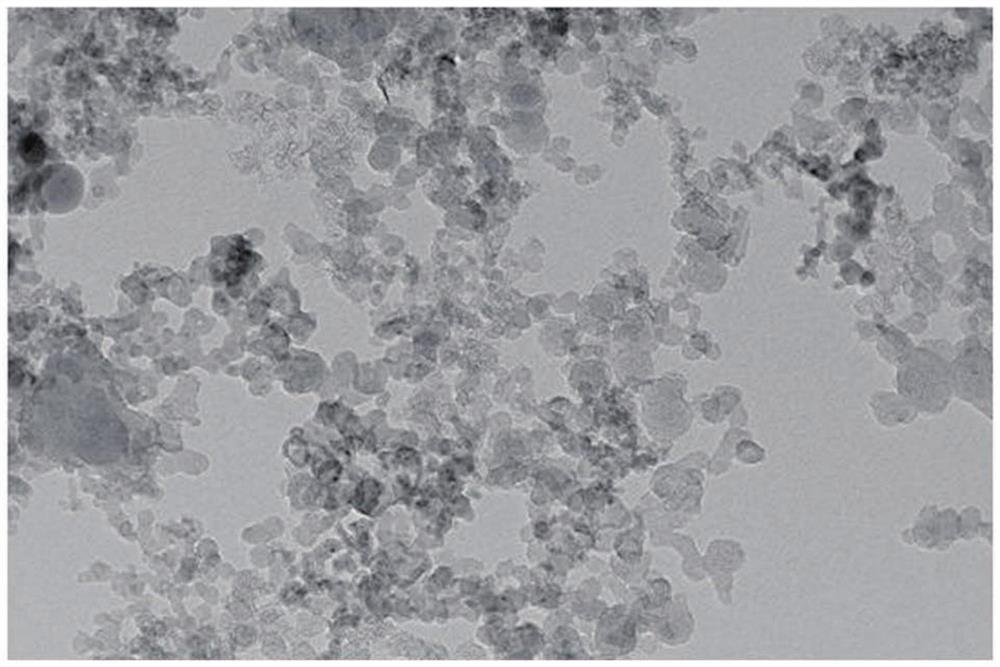

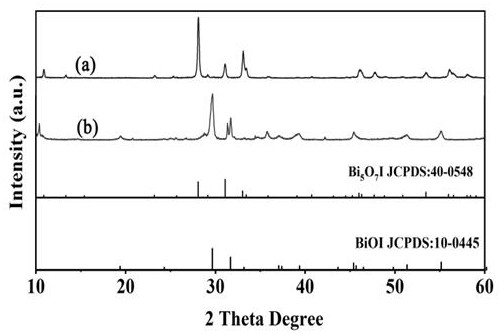

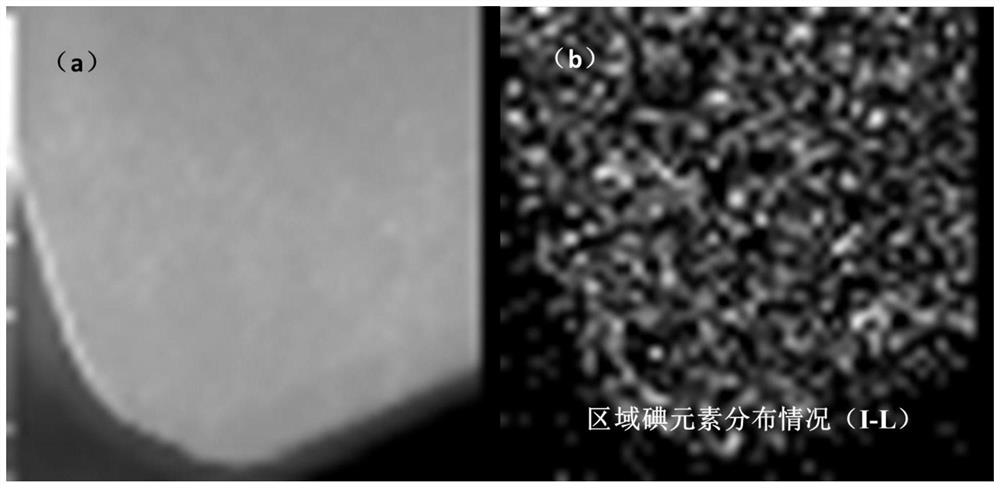

Method for preparing porous Bi5O7I material in inert atmosphere

ActiveCN113289648AMany surface defectsEffective regulation of photocatalytic performanceCatalyst activation/preparationBismuth compoundsBismuthThermal reaction

The invention relates to the technical field of preparation of porous photocatalytic materials, and particularly provides a preparation method of a porous Bi5O7I material. Specifically, iodized salt and bismuth salt are dissolved in water, pH and nitrate concentration are adjusted, a hydrothermal reaction is performed to obtain an intermediate product A, and the intermediate product A is calcined in an inert atmosphere to obtain a porous Bi5O7I sample. The prepared Bi5O7I sample is obtained in the inert atmosphere, and compared with an eutrophic condition, the Bi5O7I sample is higher in catalytic activity. Pore structures are uniformly distributed on the surface of the prepared material, and the sizes of the pore structures can be adjusted along with change of technological parameters. The prepared porous Bi5O7I material has abundant surface defects, and the photocatalytic performance of the porous Bi5O7I material can be effectively regulated and controlled. The preparation method is easy to adjust, simple to operate, mild in reaction condition and suitable for large-scale industrial production.

Owner:SHANDONG UNIV OF TECH

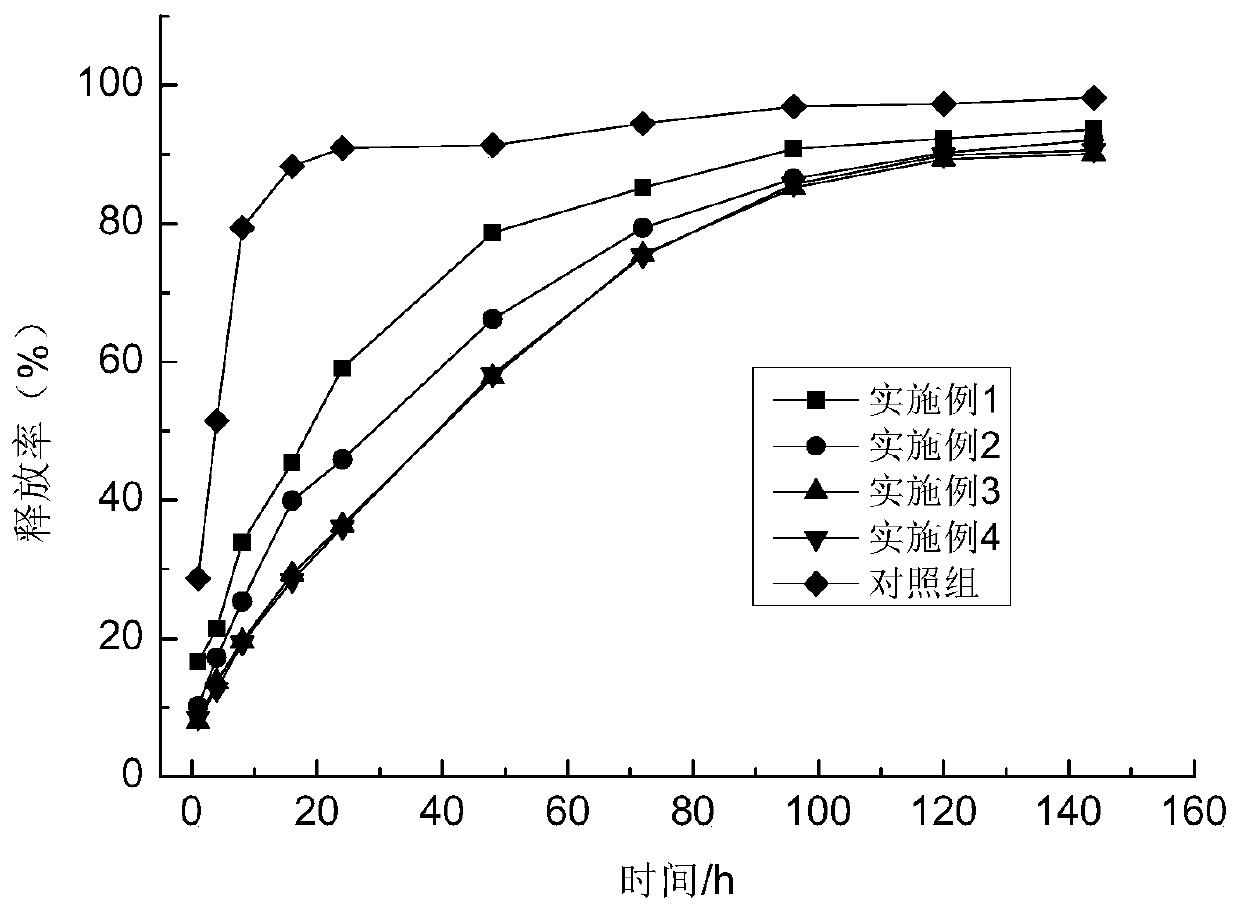

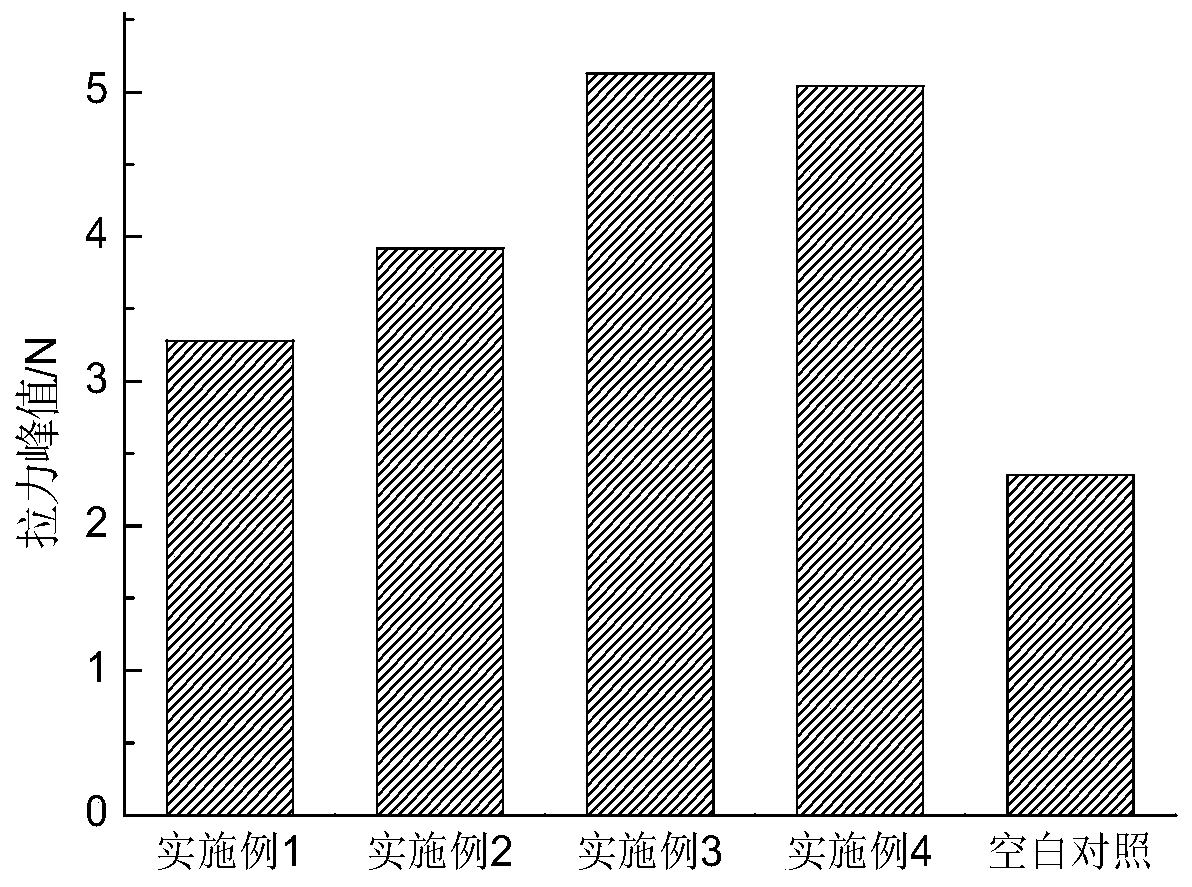

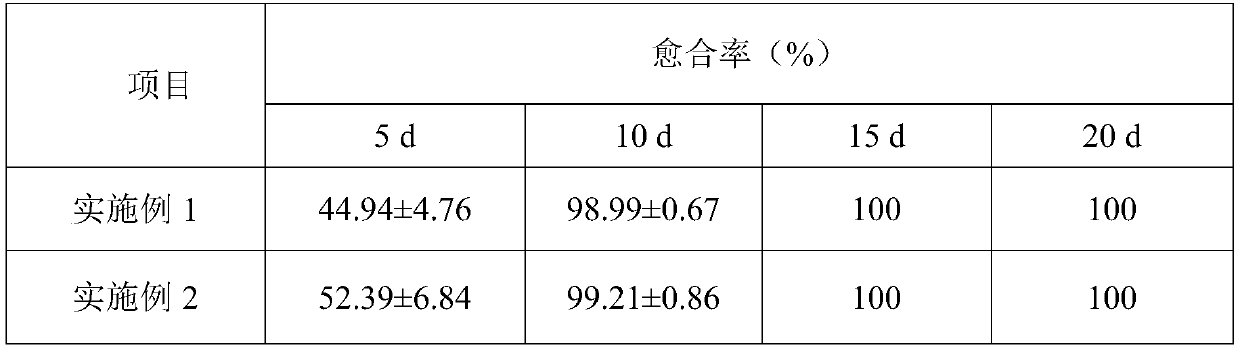

A kind of hydrogel with micro-current and sustained drug release, its preparation method and application

ActiveCN106362202BEasy to controlImprove mechanical propertiesElectrotherapyMagnetotherapy using permanent magnetsCarboxymethyl cellulosePromotion effect

The invention discloses hydrogel with microcurrent and a medicine slow-release function and a preparation method and application. The preparation method comprises the following steps: carrying out reaction on a medicine and a carbon quantum dot so as to obtain a medicine-carried carbon quantum dot; uniformly mixing a sodium alginate solution, a sodium carboxymethyl cellulose solution, a power generation substance, the medicine-carried carbon quantum dot and anhydrous calcium carbonate powder so as to obtain mixed liquid A; adding glucose lactone into the mixed liquid A, uniformly stirring, performing ultrasonic defoaming, leveling, and drying, thereby obtaining the hydrogel with the microcurrent and the medicine slow-release function. The hydrogel has the advantages of excellent mechanical property, very good medicine slow-release property, very good heal promotion effects, very good swelling property, very good biological security and large market application prospect.

Owner:广东省科学院生物与医学工程研究所

A cleaning method for iron core used for winding ≤0.1mm thick silicon steel strip

The invention discloses an iron core cleaning method used for winding a thick silicon steel strip with a thickness smaller than or equal to 0.1 mm. The iron core cleaning method comprises the following steps: cleaning the surface of an iron core with water for a first time; removing water drops on the surface; carrying out spraying type pickling on the cutting surface of the iron core; dropwise adding an acid solution on the surface of the iron core; cleaning with water for a second time; carrying out spraying type alkaline washing; cleaning with water for a third time; carrying out air-cooling by use of nitrogen gas; drying the iron core under a vacuum state; and cleaning a next iron core according to the steps. According to the iron core cleaning method disclosed by the invention, the end surface of the iron core is processed after cutting and grinding, scrap iron adhered between layers is removed through corrosion, a silicon steel layer on the iron core is guaranteed to be not corroded, and the surface of the iron core does not get rusty after being cleaned. With the adoption of the iron core cleaning method, service cycle is obviously prolonged, a product qualification rate is increased to be 95% or higher from original 85%; and moreover, end surface electrical resistivity of the iron core achieves 95% or higher of a theoretical value.

Owner:武汉研道科技有限公司

Preparation method of hmx/anpyo co-crystal under confined doping conditions for two-dimensional materials

ActiveCN112266311BLow costSimple methodNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsExplosive ingredient compoundingChemical physicsNitrate salts

The present invention relates to a preparation method of HMX / ANPyO eutectic under the confinement doping condition of a two-dimensional material. Triaminoguanidine nitrate (TAGN) is mixed with dimethyl sulfoxide (DMSO), and then HMX and ANPyO are added and waited for Dissolve completely, add glyoxal to obtain a two-dimensional conjugated structure material; grow HMX / ANPyO on this two-dimensional conjugated structure, and obtain HMX / ANPyO co-crystal under confined doping conditions. The method of the invention is simpler, the final material structure and performance can be precisely controlled through reaction conditions and doping amount, the product yield is high, the cost of raw materials used is low, and industrial production is easy to realize. Secondly, under the confinement doping conditions of two-dimensional materials, its crystal stiffness and molecular order packing density are improved, thereby improving its detonation performance. Finally, under the confinement doping conditions of 2D materials, HMX and ANPyO can form co-crystals in any ratio, and the experimental conditions are easy to control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of preparation method and application of porous carbon

ActiveCN109467073BEfficient captureImprove the capture effectOther chemical processesWater contaminantsPorous carbonFreeze-drying

The invention discloses a preparation method and application of porous carbon. Its preparation method includes (1) placing certain moisture, boron-containing salts and biofunctional macromolecules (containing amino and carboxyl groups) in a steamer-shaped container and heating the water vapor to a certain temperature to cause it to lose its original spatial structure and denature . (2) The obtained precursor particles are freeze-dried to form a "honeycomb" structure material composed of nanosheets; (3) Use electron beam radiation to heat and modify to obtain functions containing sulfur, boron, nitrogen and bulk defects The porous nano-sheet carbon material shows a good trapping effect for organic chemical wastewater. The invention realizes the removal of the ultra-low concentration organic matter in the chemical waste water through the organic matter in the chemical waste water captured by functionalized functional groups and defects.

Owner:JIANGSU TIANYU ENVIRONMENTAL PROTECTION GRP CO LTD +1

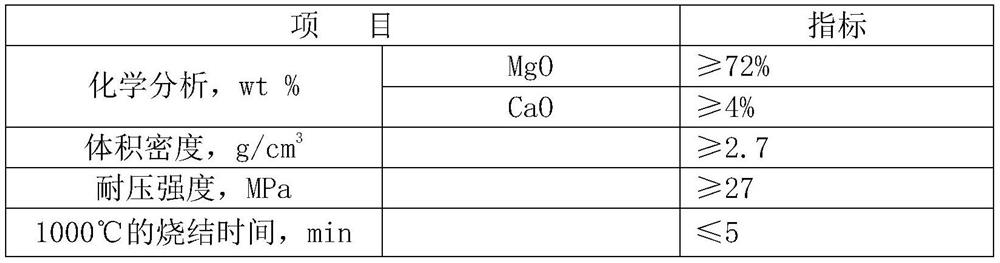

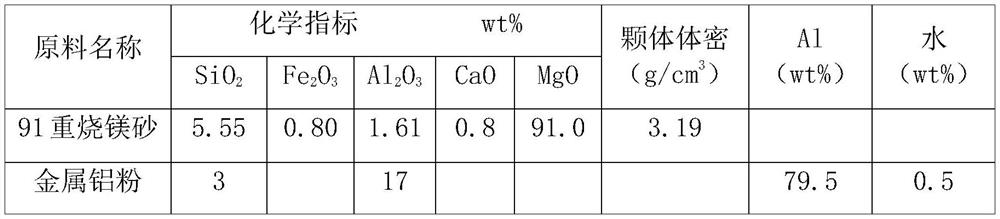

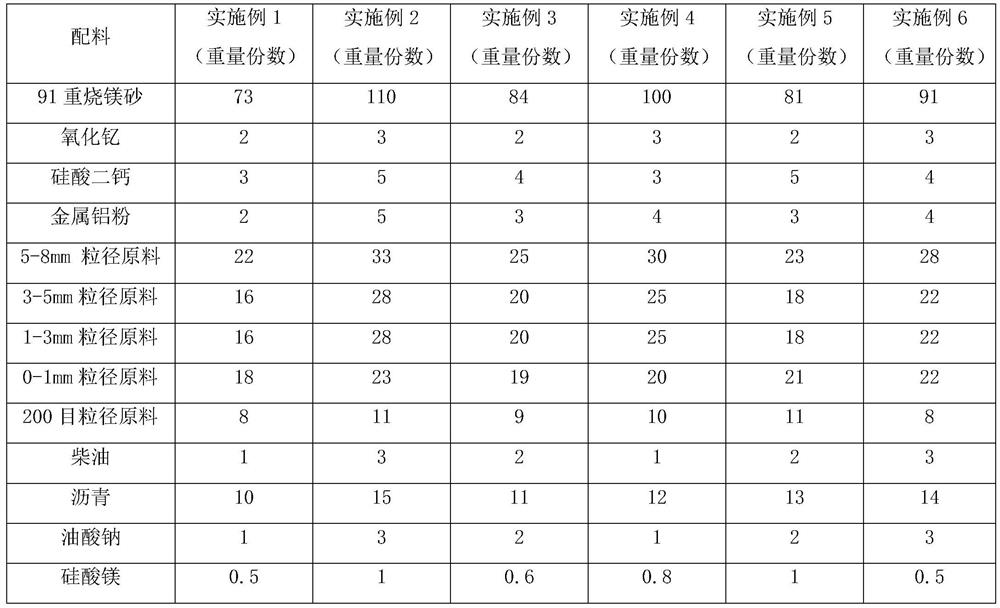

A kind of converter large surface repair material and preparation method thereof

ActiveCN106977214BImprove high temperature flexural strengthImproved thermal shock stabilityAl powderMetallic aluminum

The invention discloses a large-area repairing material for a converter and a preparation method of the large-area repairing material for the converter. The preparation method comprises the following steps of sintering dead-burned magnesia with metallic aluminum powder, yttrium oxide and dicalcium silicate at a temperature of about 1550 DEG C to prepare a prefabricated preparation material with a high high-temperature mechanical property through a pre-sintering method, taking the prefabricated preparation material with different grain compositions as aggregates of the repairing material, and meanwhile taking modified asphalt prepared from asphalt, sodium oleate and magnesium silicate as a bonding agent. The large-area repairing method disclosed by the invention has the advantages that the thermal shock resistance and high temperature bending strength are effectively improved, and the chemical corrosion resistance is improved at the same time.

Owner:海城利尔麦格西塔材料有限公司 +1

Polyethylene solid-wall permeation pipe for rainwater collecting and preparing method thereof

ActiveCN110105650AReduce the impact of recyclingImprove anti-mold and anti-bacterial propertiesGeneral water supply conservationSynthetic resin layered productsProcedure AgentsQuantum dot

The invention discloses a polyethylene solid-wall permeation pipe for rainwater collecting and a preparing method thereof, and relates to the technical field of tubular products. The polyethylene solid-wall permeation pipe for rainwater collecting comprises an outer layer, a middle layer and an inner layer from outside to inside. The middle layer comprises, by weight, 100-125 parts of PE, 1-5 parts of a mildew-proof additive, 0.5-1.0 part of a micropore agent, 0.5-1.0 part of a compound stabilizer, 1.0-1.2 parts of a processing aid and 0.5-0.8 part of a color master batch from outside to inside. The mildew-proof additive is a modified silicon dioxide / zinc sulfide quantum dot compound, and modified mesoporous silicon dioxide small spheres serve as the carrier and are loaded with silver-doped zinc sulfide quantum dots. According to the polyethylene solid-wall permeation pipe for rainwater collecting and the preparing method thereof, the mildew-proof additive is added to the formula, thetubular product has good mildew-proof and antibacterial effects, mildew can be effectively prevented from growing on a pipe wall, and the influences on rainwater recycling are reduced.

Owner:杭州联通管业有限公司

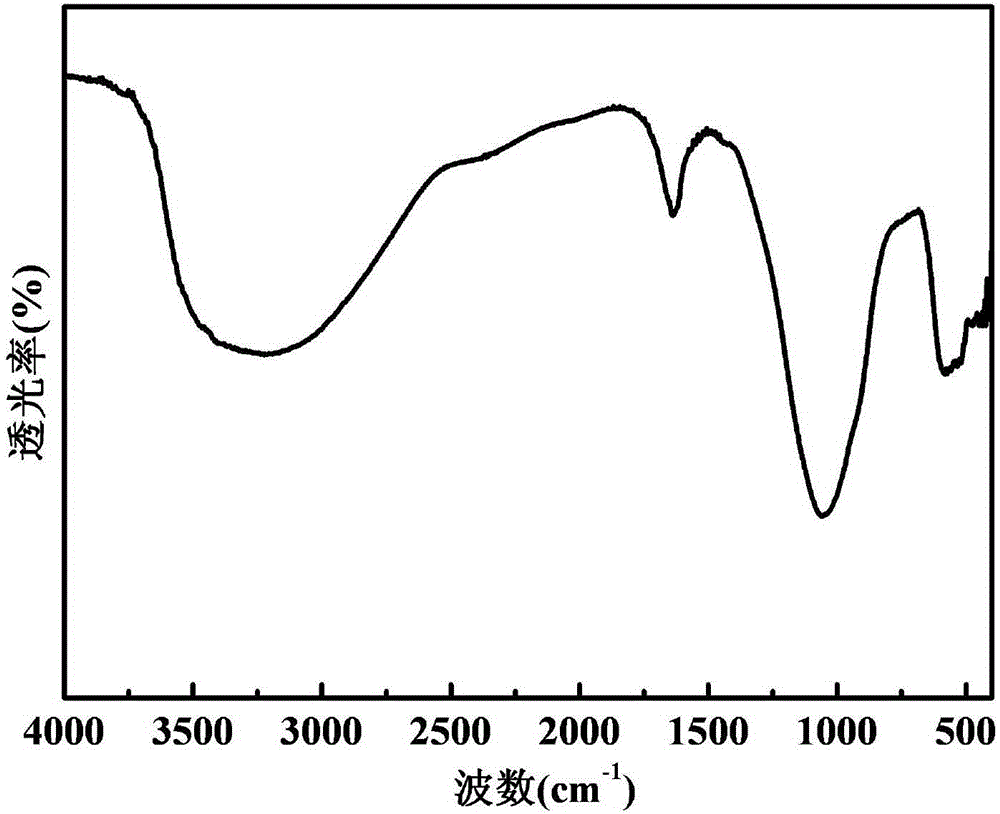

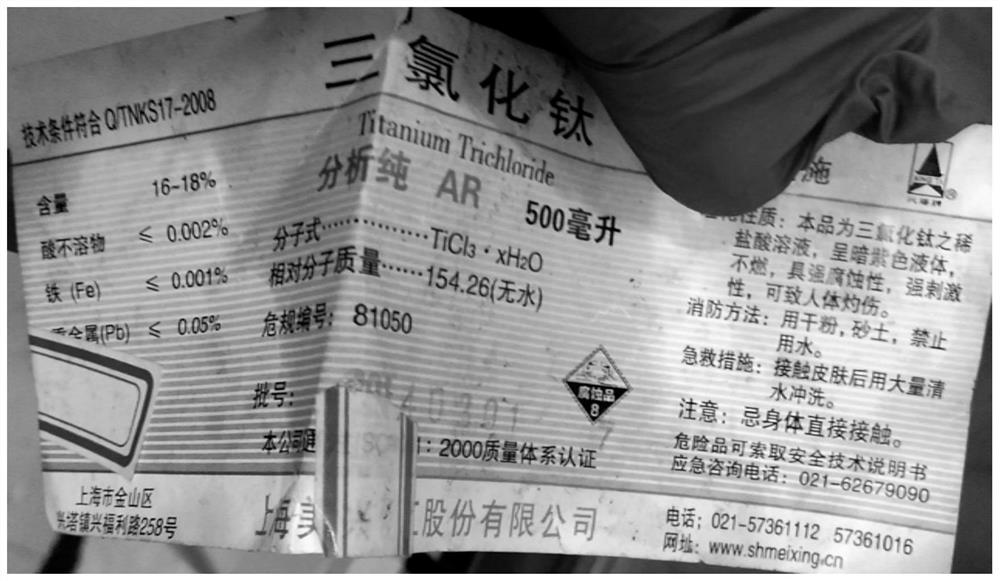

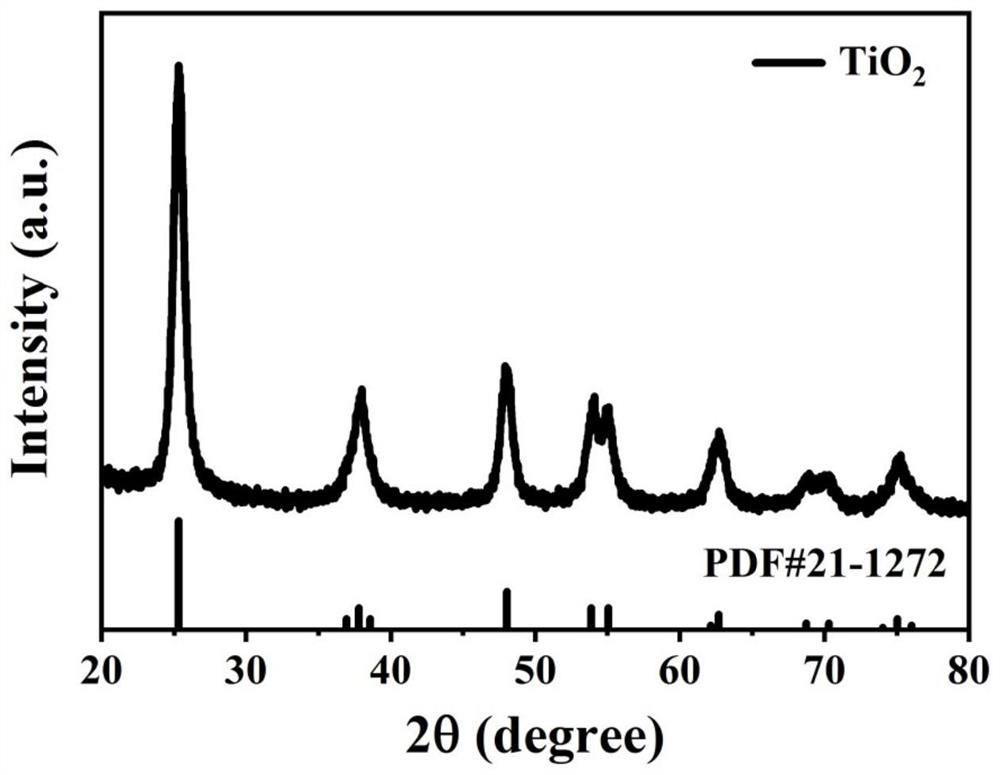

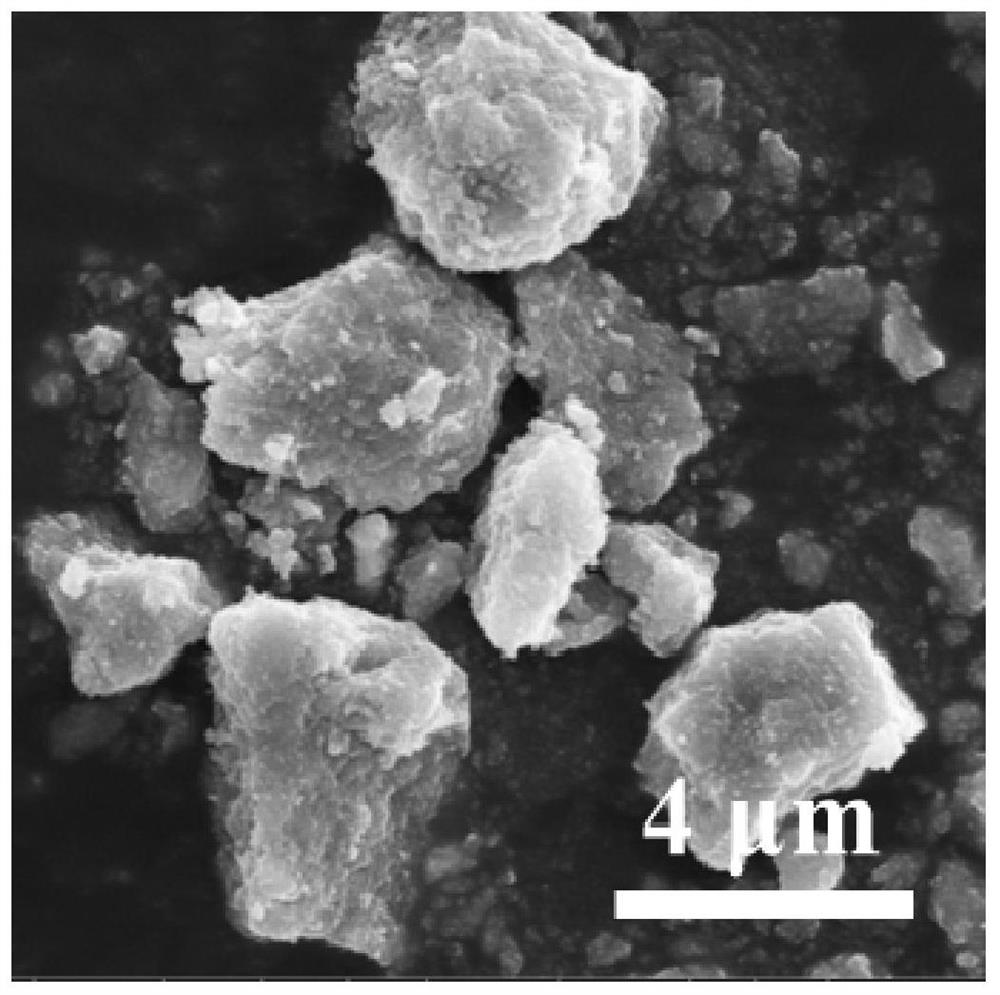

Titanium dioxide photocatalytic material as well as preparation method and application thereof

InactiveCN113318723ASafe Surface DefectsMany surface defectsPhysical/chemical process catalystsDispersed particle separationTitanium oxidePhotochemistry

The invention provides a titanium dioxide photocatalytic material and a preparation method and application thereof. The method comprises the following steps: dissolving a diluted hydrochloric acid solution of titanium trichloride in absolute ethyl alcohol, wherein the volume ratio of the solution to the absolute ethyl alcohol is (1.435-5.74): (30-40), thereby preparing a precursor solution; carrying out hydrothermal treatment on the precursor solution for 5-12 hours to obtain a reaction solution; and cooling the reaction liquid, separating a product, and sequentially cleaning with ethanol and drying to obtain the titanium dioxide photocatalytic material. The TiO2 material has abundant surface defects and a large specific surface area, and the forbidden bandwidth of the material is reduced, so that the light absorption of the material is expanded to a visible region, and the reaction active sites on the surface of the material are increased; the surface defects can capture photo-induced electrons, so that the recombination rate of photo-induced carriers is reduced; thereby, more reaction active species are generated, so that the performance of photocatalytic hydrogen production and removal of NO in air is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for preparing CO by reverse water gas shift method and preparation method thereof

ActiveCN110479323BImprove efficiencyMany surface defectsPhysical/chemical process catalystsCarbon monoxidePtru catalystPhysical chemistry

The invention provides a catalyst for preparing CO by a reverse water gas shift method and a preparation method thereof, the catalyst expression is Pd-I / CeO 2 , wherein the mass percentage of Pd is 1-4wt.%, and the surface I / Pd molar ratio is 0.2-0.5. The present invention finely controls the preparation process of the catalyst, first expands the crystal lattice of cerium oxide through chlorine atoms, then dopes iodine atoms into the catalyst, and finally removes the excessively doped iodine element through the oxidation-reduction cycle process to obtain a catalyst with a specific structure and performance catalysts. The catalyst is used in the reaction of preparing CO by the reverse water gas shift method, the conversion rate of CO in the reaction zone of 400-600 DEG C is 26.2-50%, and the selectivity of CO is 97-99%. Significantly higher than existing catalysts.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com