Nano manganese oxide molecular sieve for room temperature efficient nitrogen oxide removal and preparation method thereof

A technology of nitrogen oxides and manganese oxides, which is applied in the field of catalysis and environmental pollutant treatment, can solve the problems of short catalyst activity duration, high adsorption efficiency, and inaccessibility, and achieve enhanced adsorption storage capacity, high catalytic activity, and high adsorption The effect of storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Another aspect of the present invention provides a method for preparing the above-mentioned nano-manganese oxide molecular sieve. In the present invention, an ultrasonic-assisted preparation method is preferably used. Specifically, as an example, the preparation method of the present invention may include the following steps.

[0032] (1) Mix the divalent manganese salt, alkaline earth metal salt, and dilute acid uniformly to prepare the first mixed solution. Among them, the divalent manganese salt and the alkaline earth metal salt can be proportioned according to the doping amount of the above alkaline earth metal ions. That is, if the doping amount is 10%, the molar amount of the alkaline earth metal salt can be made 10% of the molar amount of the divalent manganese salt. The order of addition of the divalent manganese salt, alkaline earth metal salt, and dilute acid is not limited. For example, the divalent manganese salt can be dissolved in the dilute acid first, and...

Embodiment 1

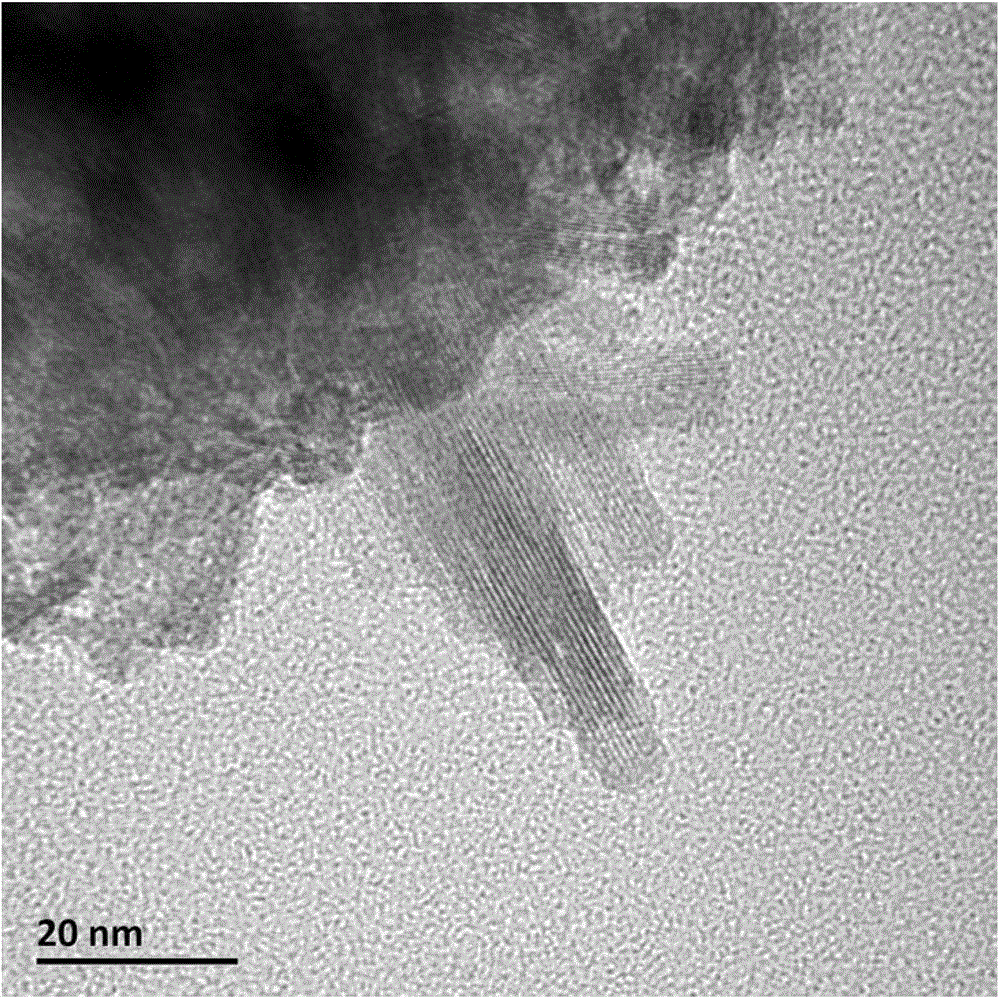

[0046] At room temperature, dissolve 1.76g of manganese sulfate in acidified deionized water (6ml of deionized water + 1.4ml of concentrated nitric acid), then add magnesium sulfate at a ratio of 10%, and stir until the mixed solution is clear. Then add potassium permanganate solution (1.178g potassium permanganate dissolved in 20ml deionized water) dropwise while stirring rapidly. After the addition is complete, immediately put the resulting mixed solution into an ultrasonic water bath (ultrasonic power is 350W). The temperature of the ultrasonic water bath is controlled by external circulating water. After 3 hours of sonication, the mixed product was separated by filtration and washed with deionized water. After the separated product is dried at 120°C / 12 hours, a magnesium-doped nano-manganese oxide molecular sieve is obtained.

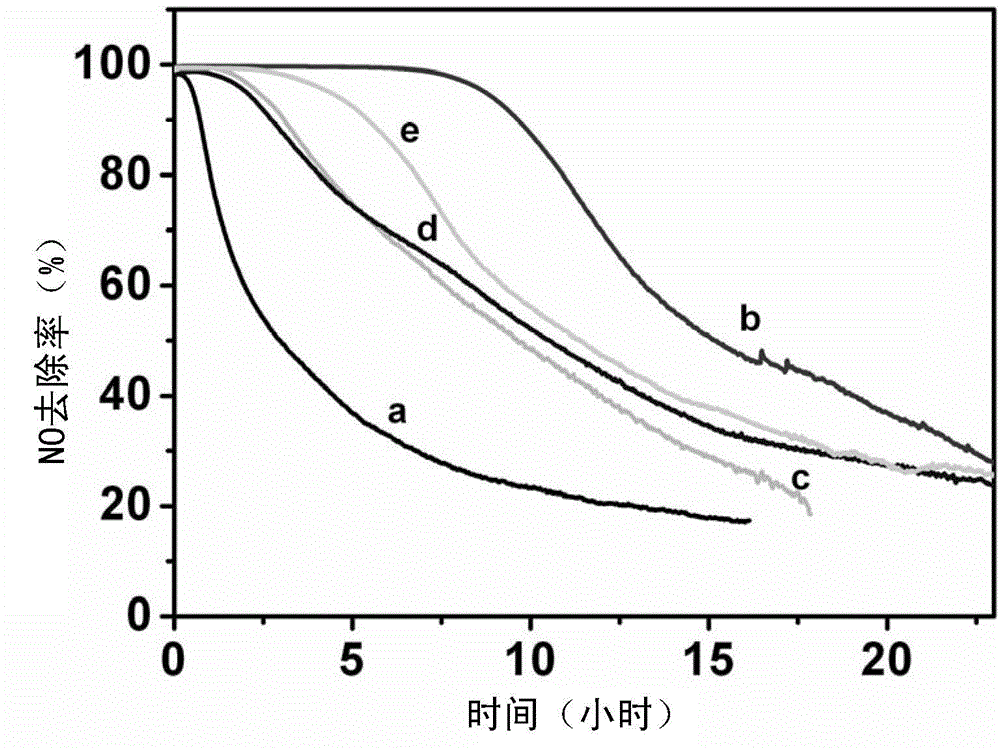

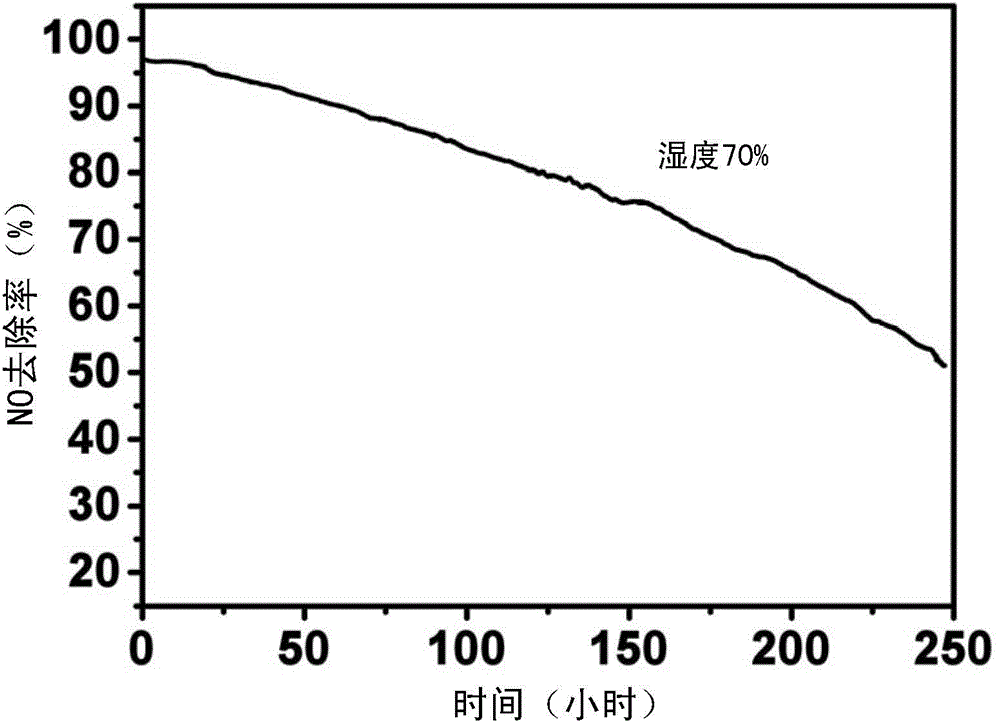

[0047] Test 1: Take 0.1 g of the prepared magnesium-doped nano-manganese oxide molecular sieve and put it into a quartz "U"-shaped reactor. The com...

Embodiment 2

[0050] Magnesium sulfate was added at a ratio of 5%, and the other methods were the same as in Example 1. According to the test results of test one in Example 1, see figure 2 The curve (a).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com