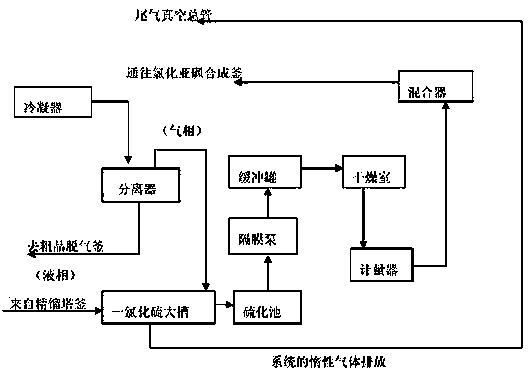

Pressure-relief discharge, absorption, treatment and recycling method in production process of thionyl chloride

A technology for thionyl chloride and production process, which is applied in the fields of pressure relief, exhaust, absorption and recycling in the production process of thionyl chloride, can solve problems such as unbalanced synthesis reaction and system pressure increase, and improve production efficiency , the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

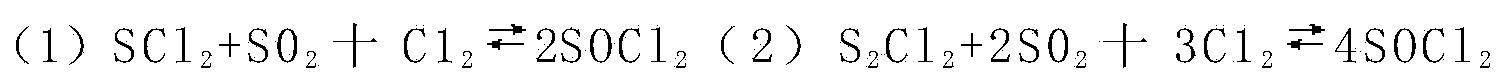

Method used

Image

Examples

Embodiment 1

[0023] When the reaction just started, add the sulfur monochloride liquid that liquid level is 60% in the sulfur dichloride synthesis kettle, pass into chlorine gas 106M 3 / h, feed sulfur dioxide into the mixer, the flow rate is 58M 3 / h, the flow ratio of chlorine and sulfur dioxide is 1.83, when the system pressure is 0.16MPa, the sulfur monochloride tank is opened, the gas in the separator and rectification tower is discharged into the sulfur monochloride tank, and the system pressure is at After an instant rise, it begins to fall. After 3 minutes, the system pressure drops to 0.13MPa, the inlet end of the sulfur monochloride tank is automatically closed, and the gas enters the buffer tank through the diaphragm pump. Two hours after the reaction started, the pressure in the buffer tank was 0.25MPa, and the sulfur dioxide content was measured as 99.3% after the sample was taken out and dried.

Embodiment 2

[0025] Six hours after the reaction started, when the gas pressure in the buffer tank reached 0.25MPa, it was detected that the purity of the dried sulfur dioxide was 99.0%, and the gas in the buffer tank was released. When the sulfur monochloride tank was closed, the diaphragm pump did not work When, open the exhaust valve on the large tank of sulfur monochloride, and close after this process lasts one minute.

Embodiment 3

[0027] Ten hours after the reaction started, the gas pressure in the buffer tank reached 0.25 MPa again, and the purity of the dried sulfur dioxide was 99.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com