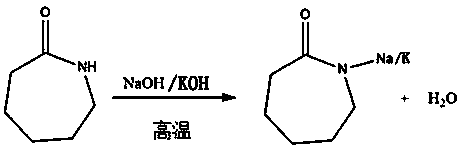

Synthetic method of 1,1'-dicaprolactam disulfide

A technology of dithiodicaprolactam and caprolactam, which is applied to the synthesis of rubber vulcanizing agent 1,1'-dithiodicaprolactam (DTDC) and the synthesis field of 1,1'-dithiodicaprolactam, can solve the problem of product Low yield, complex material recovery process, waste of caprolactam, etc., to achieve the effect of simple production process, strong operability, and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

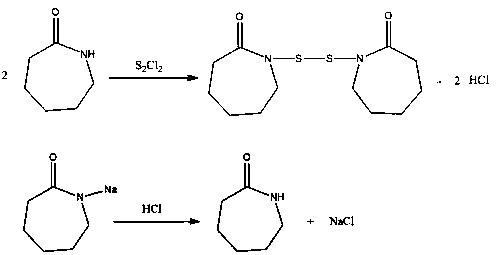

Method used

Image

Examples

Embodiment 1

[0027] Add 200g of caprolactam to a 1L reactor and slowly raise the temperature to 130°C. At this time, the caprolactam is in a molten state. Turn on the stirring. Under the condition of 0.1MPa, the water in the system is pumped out under reduced pressure for about 10 minutes; the temperature is slowly raised to 140°C and 67.15 is added. g sodium hydroxide solid, continue to pump out the water generated by the reaction under the condition of 0.1MPa under reduced pressure. After about 30 minutes, no water is distilled out in the system and the liquid level of the system is calm and bubble-free. Pour out slowly and cool to room temperature , Store in a dry place for later use after crushing. If not enough, you can repeat this step to prepare more sodium caprolactam.

[0028] According to the same method as above, the solid sodium hydroxide is replaced with an equimolar solid potassium hydroxide to obtain the potassium caprolactam salt.

Embodiment 2

[0030] Add 80.42g of caprolactam sodium salt prepared in Example 1, 5.82g of caprolactam, 550g of 120# solvent naphtha into a 1L reaction kettle, control the temperature to 35°C, turn on the stirring, and slowly drop 38.32g of sulfur monochloride into the system, After about 2h, the dropwise addition of sulfur monochloride was completed, and the temperature was maintained to continue stirring for about 2.5h, and the reaction was completed. Add 200g of water for washing, stir for 15 minutes, filter with suction and then dry the filter cake to obtain 75.68g of white solid powder with a yield of 92.47%. The melting point is 132-136°C by DSC, which is measured by HPLC. The purity is 99.06%.

Embodiment 3

[0032] Add 89.41g of caprolactam sodium salt prepared in Example 1, 6.14g of caprolactam, 600g of 120# solvent naphtha into a 1L reaction kettle, control the temperature to 35°C, turn on the stirring, and slowly drop 42.53g of sulfur monochloride into the system, After about 2.5h, the dropwise addition of sulfur monochloride was completed. Keep the temperature and continue to stir for about 2.5h, and the reaction was completed. Add 200g of water for washing, stir for 15 minutes, filter with suction and then dry the filter cake to obtain 83.41g of white solid powder with a yield of 91.83%. The melting point is 133-137℃ by DSC, and it is measured by HPLC. The purity is 99.17%.

[0033] Regarding the recovery of caprolactam, the waste water containing caprolactam and sodium chloride produced by multiple reactions can be collected, concentrated, and then extracted with toluene for multiple times, and then distilled under reduced pressure to obtain caprolactam to complete the recovery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com