Polyester enamelled wire enamel removing process and device

A polyester paint and paint stripping technology, which is applied in the field of enameled wire paint stripping, can solve the problems of difficult waste water treatment, inability to recycle, poor operating conditions, etc., achieves simple preparation and use operation methods, is conducive to industrial production, and is suitable for use. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

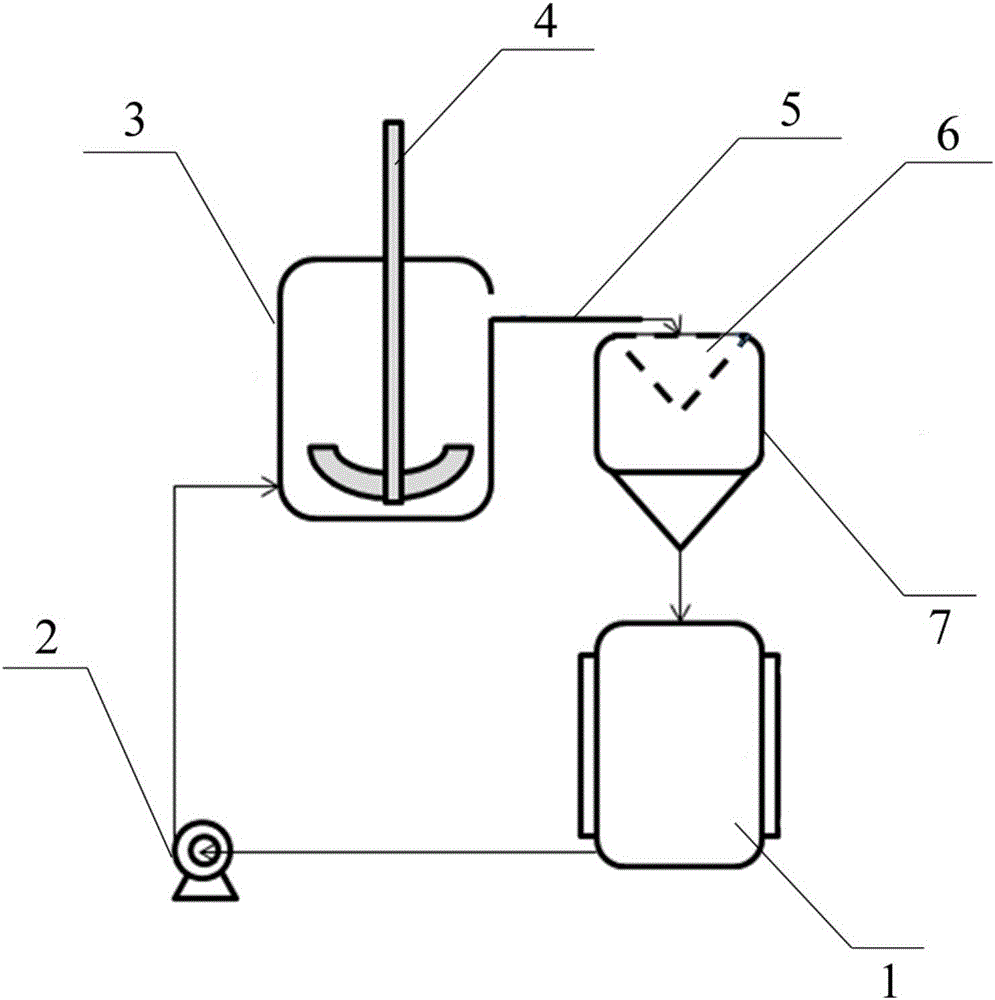

Embodiment 1

[0031] Prepare 30% aqueous sodium hydroxide solution in the lye tank as a paint remover and heat it to 90°C. Quickly pump paint stripper from lye tank into 1m with anchor paddle 3 In the paint stripping bucket, the pump speed of the paint stripper is 3m 3 / h. When overflow begins to appear, start stirring at a speed of 150 revolutions per minute. Put 0.5 tons of polyester enameled wire into the paint stripping bucket, immerse them all in the paint stripper, when the temperature in the paint stripping bucket reaches 90°C, start timing. After 1 hour, the paint film on the enameled wire all falls off, and overflows into the filter barrel for removing paint film with the lye, and the peeled paint film becomes flakes, and is filtered and recovered through the filter bag. The surface of the obtained copper wire is bright, the paint stripper can be recycled, and the paint stripping effect remains unchanged.

Embodiment 2

[0037] Prepare 10% potassium hydroxide aqueous solution in the lye tank as a paint remover, and heat it to 105°C. Quickly pump the paint stripper in the lye tank into the 1m with 45° inclined paddle 3 In the paint stripping bucket, the pump speed of the paint stripper is 6m 3 / h. When overflow begins to appear, start stirring at a speed of 300 revolutions per minute. Put 0.5 tons of polyester enameled wire into the paint stripping bucket, immerse them all in the paint stripper, when the temperature in the paint stripping bucket reaches 105°C, start timing. After 2.5 hours, the paint film on the enameled wire falls off completely, and overflows with the lye into the filter barrel for removing the paint film. The peeled paint film becomes flakes and is filtered and recovered through the filter bag. The surface of the obtained copper wire is bright, but there are a small amount of black spots on the surface of the copper wire, the paint remover can be recycled, and the paint r...

Embodiment 3

[0039] Prepare 40% aqueous sodium hydroxide solution in the lye tank as a paint remover and heat it to 90°C. Quickly pump paint stripper from lye tank into 1m with anchor paddle 3 In the paint stripping bucket, the pump speed of the paint stripper is 5m 3 / h. When overflow begins to appear, start stirring at a speed of 30 revolutions per minute. Put 0.5 tons of polyester enameled wire into the paint stripping bucket, immerse them all in the paint stripper, when the temperature in the paint stripping bucket reaches 90°C, start timing. After 0.45 hours, the paint film on the enameled wire falls off completely, and overflows with the lye into the filter barrel for removing the paint film, and the peeled paint film becomes flakes, and is filtered and recovered through the filter bag. The surface of the obtained copper wire is bright, the paint stripper can be recycled, and the paint stripping effect remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com