Paint remover for removing cathodic electrophoretic paint film on surface of steel plate

A technology of cathodic electrophoresis and paint stripper, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problem of large and long metal surface corrosion, which generally takes dozens of hours, etc., achieves low human toxicity, The effect of rapid paint stripping and shortened analysis and evaluation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

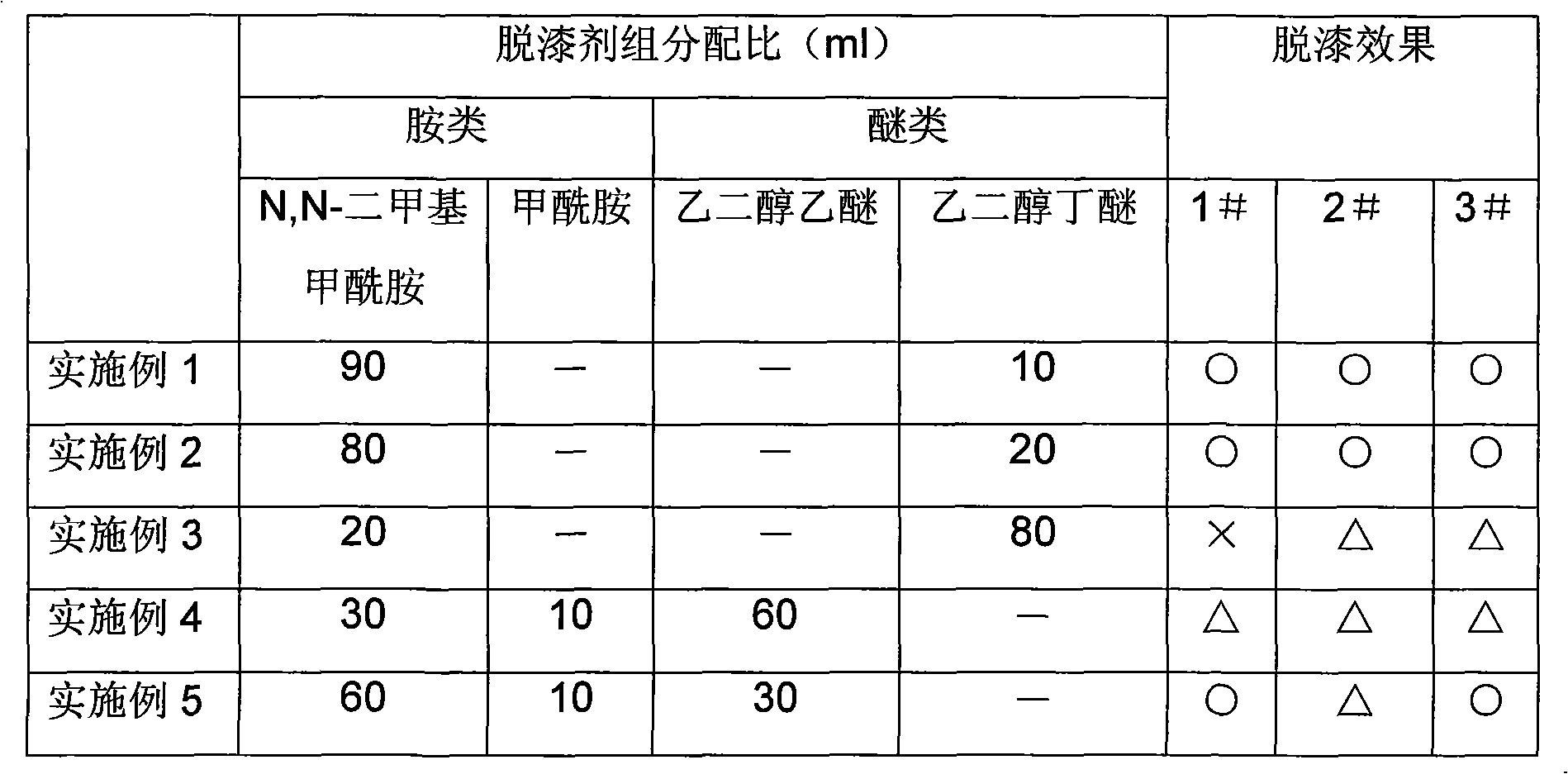

[0020] 1. Preparation of paint remover: Take 90ml of N,N-dimethylformamide (DMF) and 10ml of ethylene glycol butyl ether, and mix them evenly.

[0021] 2. Paint stripping test: Place 1#, 2#, and 3# samples in flat-bottomed conical flasks filled with paint remover, install an air condenser at the mouth of the bottle, and heat them in a water bath at 60°C for 8 minutes. The paint film begins to swell and break away from the surface of the steel plate, cool at room temperature, rinse the residual paint film on the surface of the steel plate with distilled water, and air dry.

Embodiment 2

[0023] 1. Preparation of paint remover: Take 80ml of N,N-dimethylformamide (DMF) and 20ml of ethylene glycol butyl ether, and mix them evenly.

[0024] 2. Paint stripping test: Place 1#, 2#, and 3# samples in flat-bottomed conical flasks filled with paint strippers, install an air condenser at the mouth of the bottle, and heat them in a water bath at 60°C for 10 minutes. The paint film begins to swell and break away from the surface of the steel plate, cool at room temperature, rinse the residual paint film on the surface of the steel plate with distilled water, and air dry.

Embodiment 3

[0026] 1. Preparation of paint remover: Take 20ml of N,N-dimethylformamide (DMF) and 80ml of ethylene glycol butyl ether, and mix them evenly.

[0027] 2. Paint stripping test: Place 1#, 2#, and 3# samples in flat-bottomed conical flasks filled with the above solutions respectively, install an air condenser at the mouth of the bottle, heat in a water bath at 60°C for 40 minutes, and then remove to normal temperature. Cool down, rinse the residual paint film on the surface of the steel plate with distilled water, and air dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com