Nontoxic environment-friendly paint remover

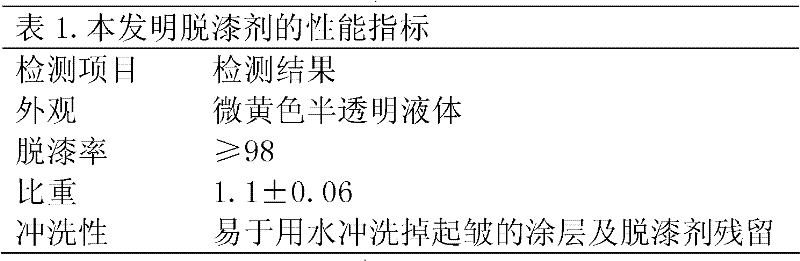

A non-toxic, environmentally friendly, paint remover technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of fast volatilization speed, serious corrosion, narrow applicable environment, etc., and achieve fast paint removal speed and flash point High, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

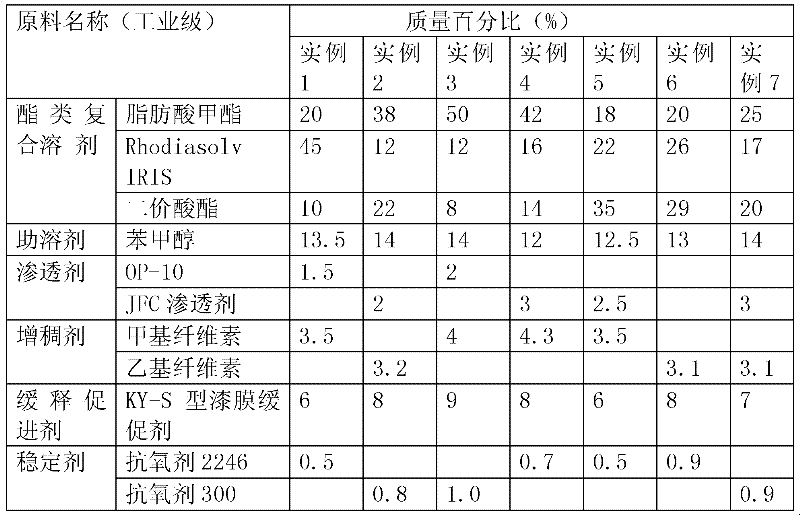

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the non-toxic and environmentally friendly paint remover of the above-mentioned embodiment: first, take the thickener and stabilizer of the formula amount and add them to benzyl alcohol for pre-dissolution, and the dissolved solution is A component for use; secondly, put the ester solvent in Mix evenly at room temperature, add penetrant and sustained-release accelerator in turn under stirring, and stir for 30 minutes to obtain component B; finally, add component A to component B under stirring and fully stir for 30 minutes, then filter. Invented non-toxic and environmentally friendly paint remover.

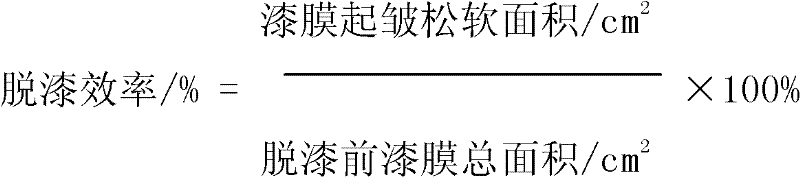

[0035] The paint stripping efficiency calculation method of nontoxic environmental protection paint stripper of the present invention is as follows

[0036] Paint stripping efficiency is one of the main indicators for testing paint stripping performance, and its test method refers to the industry standard HG / T2881 1997 "Test Method for Paint Strip...

example 2

[0039] Example 2 The non-toxic and environmentally friendly paint remover is applied on the oil storage tank to remove the paint on the polyurethane paint film within 15 minutes, and the paint removal efficiency is greater than 92%; through the application of a certain military factory, the paint on the tank surface can be removed within 10 minutes. Anti-corrosion coating, the paint removal efficiency is greater than 92%; after being tested by a certain department of the Navy, it can be painted on the deck of a ship, and the ship deck paint can be removed within 15 minutes, and the paint removal efficiency is greater than 94%; it has been applied by an electronics factory in Hebei , soak the electronic optical drive components in the paint remover of the present invention, the fluorocarbon paint can be removed within 6 minutes, and the paint removal efficiency is greater than 95%; it can be used in an auto parts factory in Anji, and the electrophoretic paint and acrylic acid can...

example 3

[0040] Example 3 The non-toxic and environmentally friendly paint remover is applied on the oil storage tank to remove the paint on the polyurethane paint film within 15 minutes, and the paint removal efficiency is greater than 90%; through the application of a certain military factory, the paint on the surface of the tank can be removed within 10 minutes. Anti-corrosion coating, the paint removal efficiency is greater than 93%; after being tested by a certain department of the Navy, it can be painted on the deck of a ship, and the ship deck paint can be removed within 15 minutes, and the paint removal efficiency is greater than 94%; it has been applied by an electronics factory in Hebei , soak the electronic optical drive components in the paint remover of the present invention, the fluorocarbon paint can be removed within 6 minutes, and the paint removal efficiency is greater than 90%; it can be used in an auto parts factory in Anji, and the electrophoretic paint and acrylic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com